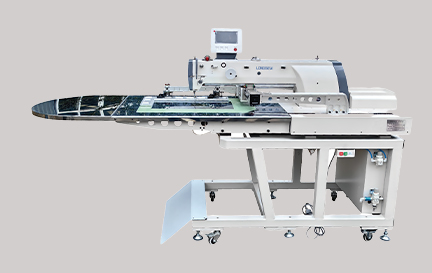

woven sack sewing machine

The Importance of Woven Sack Sewing Machines in the Packaging Industry

In today's fast-paced manufacturing environment, efficiency and quality are paramount. One crucial component of the packaging process is the sewing of woven sacks, which are widely used in various industries for transporting and storing products such as grains, seeds, and fertilizers. The primary tool for this task is the woven sack sewing machine. This article explores the significance of these machines, their functioning, and their impact on the packaging industry.

Understanding Woven Sacks

Woven sacks, often made from polypropylene or polyethylene, are known for their excellent strength, durability, and water resistance. These sacks are created through a process of weaving plastic strands into a fabric-like material. As a result, they are lightweight yet robust enough to hold substantial weights without tearing. The versatility of woven sacks makes them suitable for various applications, including agriculture, food, construction, and chemical industries.

The Role of Woven Sack Sewing Machines

Woven sack sewing machines are designed specifically for the task of closing these bags securely. Unlike traditional sewing machines that may be used on fabric, woven sack sewing machines feature adapted mechanisms to handle the toughness of woven material. They employ a variety of stitching methods, including chain stitching and lock stitching, ensuring that the sacks are not only sealed but also durable enough to withstand the rigors of transportation and storage.

One of the key advantages of using woven sack sewing machines is their ability to operate at high speeds. Modern machines can sew up to several hundred sacks per hour, significantly increasing production efficiency. This high-speed operation is essential for keeping pace with the demands of industries that rely on quick turnaround times for packaging products.

Features and Technological Advancements

woven sack sewing machine

Today's woven sack sewing machines come equipped with advanced features that enhance their functionality. Many machines are now automated, integrating digital controls that allow for precise adjustments in stitching parameters. These features not only improve the quality of the stitching but also reduce the likelihood of errors, leading to fewer defective sacks.

Moreover, advancements such as automatic roll feeders, variable speed controls, and programmable stitching patterns have made these machines easier to operate. Operators can now produce different sack sizes and designs with minimal downtime, thereby increasing overall productivity. Some machines are even fitted with sensors to detect material thickness, automatically adjusting the sewing pressure to ensure optimal results.

Economic Impact

The economic implications of woven sack sewing machines are significant. By optimizing the packaging process, businesses can reduce labor costs and waste, streamline their operations, and ultimately enhance their profitability. Efficient sewing machines also ensure that products remain safe and secure during transit, minimizing potential losses due to damaged packaging.

In a competitive market, companies that invest in high-quality woven sack sewing machines can position themselves as leaders in their respective industries. The ability to produce sturdy, reliable packaging quickly can lead to improved customer satisfaction and increased sales, solidifying a company's reputation.

Conclusion

Woven sack sewing machines play an essential role in the packaging industry, offering speed, efficiency, and quality in the production of woven sacks. The advancements in technology and automation have made these machines not only more effective but also user-friendly. As industries continue to evolve and demand greater efficiency, the reliance on these specialized machines is likely to increase. Investing in modern woven sack sewing machines is a strategic decision that can pay dividends in terms of productivity, profits, and customer trust. As such, they represent both a significant contribution to manufacturing processes and a vital tool for businesses aiming for long-term success in the competitive packaging landscape.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025