High-Quality Two Needle Lockstitch Machines for Precision Sewing

The Two Needle Lockstitch Machine An Overview

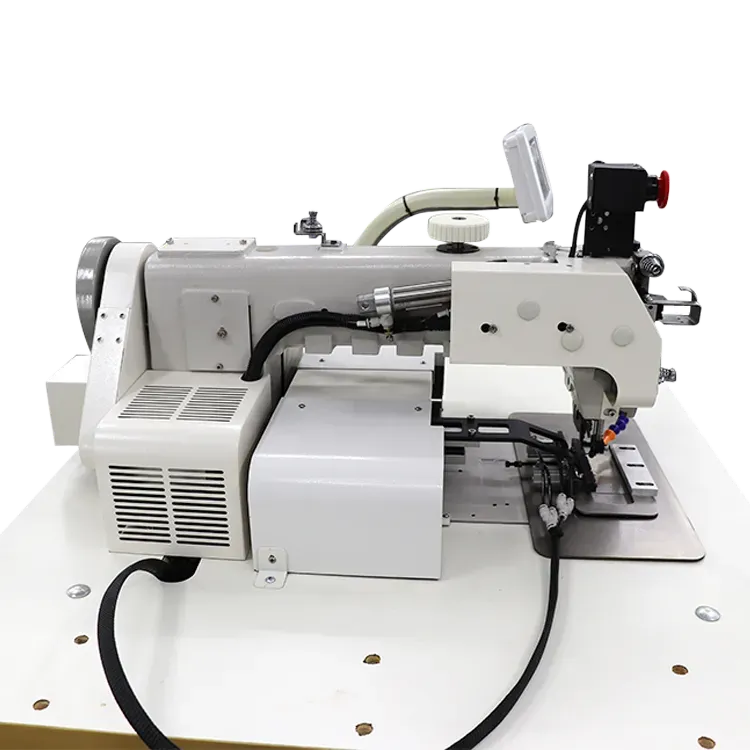

The two needle lockstitch machine represents a significant advancement in the world of textile and garment manufacturing. By employing two needles instead of one, this machine enables the creation of complex stitch patterns that are not only strong but also aesthetically pleasing. It has become an essential tool in various sectors, from apparel production to upholstery and beyond.

Design and Functionality

At its core, the two needle lockstitch machine operates on a straightforward principle it uses two needles to create a series of interlocking stitches. Each needle works in conjunction with a bobbin located beneath the fabric. As the needles penetrate the fabric, they create loops that are interlocked by the bobbin thread, forming a durable stitch. This mechanism provides significant strength and reduces the likelihood of seam rupture, making it ideal for heavy fabrics and seams subjected to stress.

One of the standout features of this machine is its ability to produce decorative and functional stitches simultaneously. Many manufacturers take advantage of this capability to create intricate designs, which can enhance the product's visual appeal while maintaining structural integrity. For instance, decorative stitching can be seamlessly integrated into the seams of jackets, bags, and other items where aesthetics and strength are both critical.

Advantages

The advantages of the two needle lockstitch machine are manifold. First and foremost, it offers increased efficiency in sewing operations. By allowing two threads to be used at the same time, it cuts down on the time required to sew products compared to single-needle machines. This efficiency is particularly beneficial in high-volume manufacturing environments, where productivity is a key consideration.

two needle lockstitch machine

Additionally, the machine's ability to create two parallel seams makes it suitable for various applications in the textile industry. It can be employed in sewing side seams of garments, attaching pockets, or working on heavy-duty bags. The parallel stitching not only improves the structural integrity of sewn items but also allows for greater flexibility in design, catering to the unique requirements of different projects.

Moreover, the two needle lockstitch machine is designed for heavy workloads. Its robust construction enables it to handle thicker materials, such as denim, canvas, and leather, which are commonly used in the production of both fashion and functional items. This versatility makes it a valuable asset for manufacturers aiming to diversify their offerings.

Challenges

Despite its many advantages, the two needle lockstitch machine is not without challenges. The complexity of operating and maintaining the machine requires skilled labor, which can be a limitation for some manufacturers. Additionally, thread tension must be meticulously adjusted to avoid issues such as thread breakage or skipped stitches. This demands a certain level of expertise and experience from the operators.

Conclusion

In conclusion, the two needle lockstitch machine has revolutionized the textile industry by providing a reliable and efficient solution for sewing operations. Its ability to produce strong, decorative stitches in a variety of materials makes it an indispensable tool for manufacturers aiming to balance quality and creativity in their products. As technology continues to evolve, these machines are likely to become even more sophisticated, offering further enhancements to functionality and efficiency. Whether in high-fashion or industrial applications, the two needle lockstitch machine is here to stay, shaping the future of garment manufacturing for years to come.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025