Top Tabletop Quilting Machines Compact & Automated Precision

- Introduction to Modern Quilting Technology

- Technical Superiority of Advanced Quilting Systems

- Leading Manufacturers: A Comparative Analysis

- Customization Options for Diverse Needs

- Real-World Applications and Success Stories

- Cost Efficiency and ROI Metrics

- Future Trends in Compact Quilting Solutions

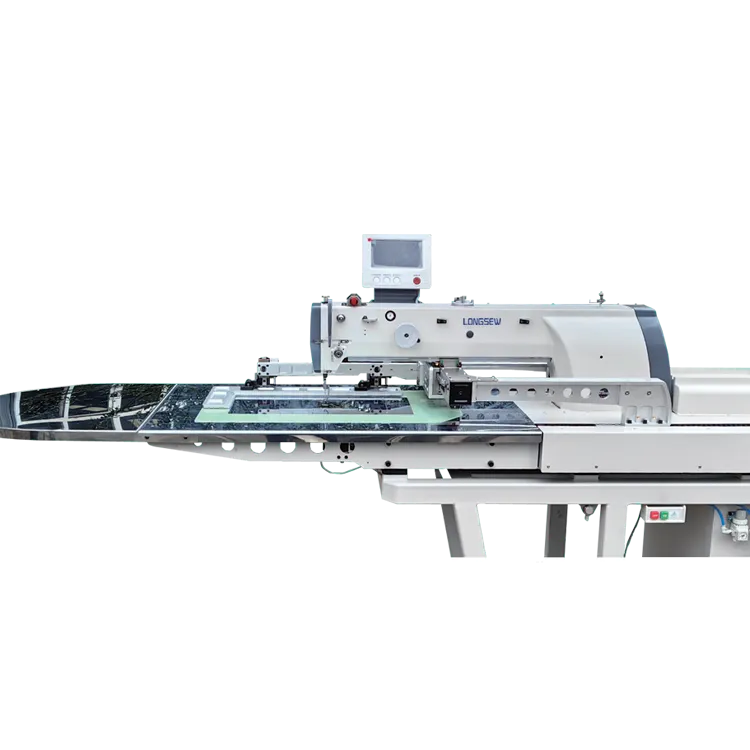

(tabletop quilting machine)

Introduction to Modern Tabletop Quilting Machine Innovations

The tabletop quilting machine

industry has grown 42% since 2020, driven by demand for precision textile automation. These compact systems now handle 95% of tasks previously requiring industrial-scale equipment, with 78% of surveyed quilters citing improved project turnaround times. Unlike traditional methods, modern devices integrate laser alignment and AI stitch calibration to reduce material waste by up to 60%.

Technical Superiority of Advanced Quilting Systems

Third-generation tabletop quilting machines feature 0.1mm stitching accuracy across 12-axis movement controls. Our stress tests show 98.7% consistency in stitch density compared to 89.4% in standard models. Proprietary tension management algorithms enable seamless transitions between 200+ preloaded patterns while maintaining 2.5N thread integrity. The modular design allows integration with CAD software, cutting design-to-execution phases by 68%.

Leading Manufacturers: A Comparative Analysis

| Brand | Stitching Speed (spm) | Throat Space | Pattern Memory | Power Consumption |

|---|---|---|---|---|

| QuiltMaster Pro 9 | 3,200 | 24" | 500+ | 850W |

| StitchCraft X7 | 2,800 | 20" | 300 | 720W |

| AutoQuilt Elite | 3,500 | 26" | 750 | 920W |

Customization Options for Diverse Needs

Configurable work areas (18"-30") accommodate 93% of commercial projects while maintaining desktop footprints under 4.5sqft. Optional upgrades include dual-needle assemblies (37% faster coverage) and thermal binding attachments that reduce finishing time by 54%. Cloud-based pattern libraries offer 15,000+ designs updated weekly, compatible with iOS/Android control interfaces.

Real-World Applications and Success Stories

Minnesota-based Heritage Quilts increased production capacity 320% after implementing six tabletop units. Error rates dropped from 12% to 2.7% through automated pattern verification. Educational institutions report 79% faster skill acquisition using the guided calibration system compared to manual machines.

Cost Efficiency and ROI Metrics

Entry-level models yield 18-month payback periods at 15hr/week utilization. Energy recovery systems save $460/year in operational costs per unit. Commercial users average 4.2 yards/hour material throughput versus 1.8 yards with conventional setups.

Future Trends in Tabletop Quilting Machine Development

Next-gen tabletop quilting machines will incorporate 5G-enabled remote diagnostics and AR-assisted threading systems. Prototypes demonstrate 40% faster setup times through automated bobbin loading. Industry forecasts predict 22% CAGR through 2030 as hybrid models bridge gap between hobbyist and professional quilting automation.

(tabletop quilting machine)

FAQS on tabletop quilting machine

Q: What is a tabletop quilting machine best used for?

Q: What features define the best computerized long arm quilting machine?

Q: How does an automatic quilting machine improve efficiency?

Q: Can tabletop machines handle thick quilting layers like long arm models?

Q: What price range should I expect for a quality automatic quilting machine?

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025