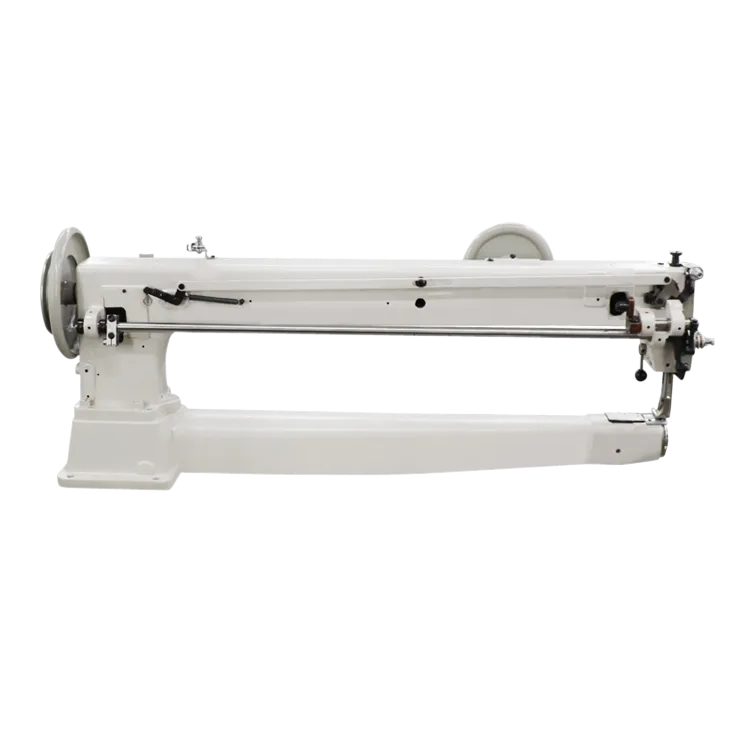

Single Needle Edge Cutting Machine for Precise Fabric Finishing and Enhanced Production Efficiency

Understanding the Single Needle Edge Cutter Machine

In the realm of textile and garment manufacturing, precision and quality are paramount. Among the various machines that contribute to an efficient and streamlined production process, the single needle edge cutter machine stands out as an essential tool. This article explores the significance, functionality, and benefits of the single needle edge cutter machine in modern manufacturing.

What is a Single Needle Edge Cutter Machine?

The single needle edge cutter machine is a specialized sewing machine designed primarily for finishing the edges of fabric and garments. Its primary function is to secure the edges of the material, preventing fraying and ensuring that the product maintains its aesthetic appeal and durability. The machine employs a single needle mechanism to provide precise stitching, allowing manufacturers to achieve clean and professional hems on a variety of fabrics.

Key Features of the Machine

One of the defining characteristics of the single needle edge cutter machine is its straightforward operational design, making it user-friendly for operators. Here are some of its notable features

1. Precision Control The machine allows for precise adjustments to stitching length and tension, ensuring a consistent quality of the finished edge irrespective of fabric type.

2. Variety of Stitch Options While it mainly uses a straight stitch, many models offer other stitching styles, such as zig-zag or overlock, to accommodate different finishing needs.

3. Speed and Efficiency Designed for high-speed operation, the machine can significantly reduce production time, allowing manufacturers to meet tight deadlines without compromising quality.

5. Versatility These machines can handle a wide range of fabrics, from lightweight materials like silk to heavier textiles such as denim, making them suitable for various garment types.

Applications in Manufacturing

single needle edge cutter machine

The versatility and precision of the single needle edge cutter machine make it invaluable in several applications within the garment industry

- Garment Finishing It ensures that all edges of garments, such as shirts, trousers, and dresses, are neatly finished, enhancing the product's overall appearance while preventing fabric wear and tear.

- Quilting and Upholstery In the quilting and upholstery sectors, this machine is used to finish seams and edges, contributing to both the functional and aesthetic quality of the final product.

- Accessory Production The machine is commonly used for creating accessories, such as bags and hats, where clean edges are critical to the product’s durability and style.

Benefits to Manufacturers

Incorporating the single needle edge cutter machine into the production process offers several benefits to manufacturers

1. Cost-Effectiveness By reducing the need for manual finishing work, manufacturers can save on labor costs and minimize the time spent on production.

2. Enhanced Product Quality The precision provided by the single needle mechanism ensures that each garment is finished to a high standard, thus elevating the overall quality of the final product.

3. Flexibility in Production With various stitching options, manufacturers can pivot quickly and adapt their production processes to meet changing market demands.

4. Reduced Waste By ensuring that edges are neatly finished, the likelihood of fabric fraying is reduced, leading to less material waste over time.

Conclusion

The single needle edge cutter machine plays a crucial role in modern garment manufacturing, providing both efficiency and precision in fabric edge finishing. As the industry continues to evolve, machines like these will remain essential tools for manufacturers seeking to enhance their productivity while maintaining the highest standards of quality in their products. Investing in a reliable single needle edge cutter machine can make a significant difference in the manufacturing process, ultimately leading to greater customer satisfaction and business success.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025