Sewing Machines for Heavy-Duty Sailcloth and Marine Fabric Projects

The Importance of Sail Cloth Sewing Machines in the Marine Industry

Sail cloth sewing machines play a crucial role in the marine industry, particularly for the manufacturing and repair of sails for boats and yachts. With the rising popularity of sailing, as well as advancements in technology and materials, the demand for high-quality, durable sails has surged. This has led to an increased importance of specialized sewing machines that can handle the unique challenges posed by sailcloth.

Understanding Sailcloth

Sailcloth is a specific type of fabric, primarily made from materials like polyester, nylon, or sometimes even natural fibers. These materials are chosen for their strength, lightweight properties, and resistance to environmental stressors such as UV rays and saltwater. However, their unique characteristics also present challenges when it comes to sewing. Sailcloth is typically thicker and tougher than regular fabric, requiring machines that can endure the extra strain and provide precise stitching to ensure the integrity and performance of the sails.

The Role of Sail Cloth Sewing Machines

Sail cloth sewing machines are engineered to tackle these challenges. Firstly, they come equipped with powerful motors and heavy-duty needles that can penetrate through multiple layers of sailcloth. Furthermore, these machines often feature specialized feed systems that ensure the even feeding of thick materials, preventing puckering or misalignment during the sewing process.

One of the most significant innovations in sail cloth sewing technology is the advent of walking foot machines. These machines utilize a mechanism that allows the upper and lower feed dogs to move simultaneously, thus providing better control over the fabric. This is particularly useful when sewing curves or handling large pieces of material, which is common in sail construction.

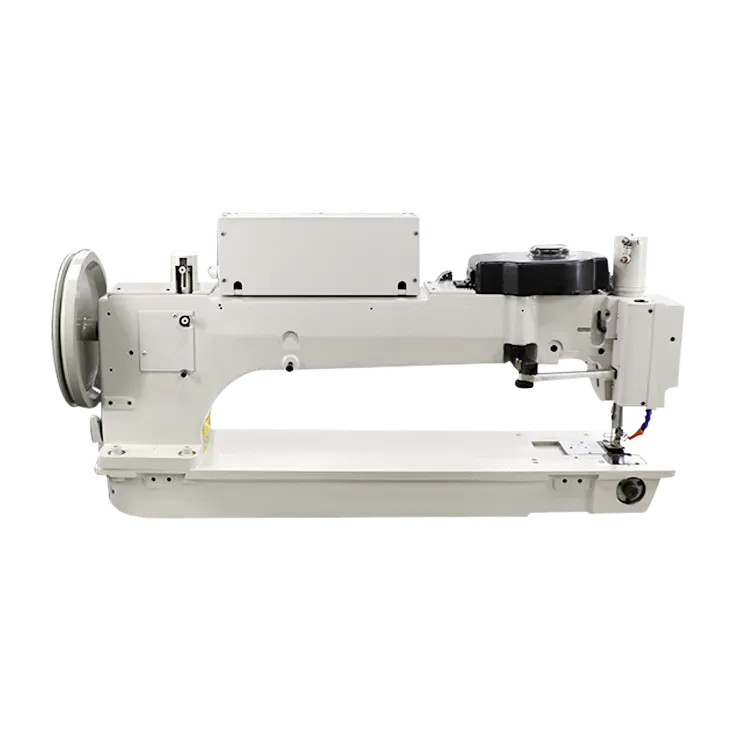

sail cloth sewing machine

The Benefits of Using Sail Cloth Sewing Machines

Utilizing sail cloth sewing machines not only enhances the quality of the finished product but also improves efficiency in production. With the right equipment, sailmakers can produce sails that are not only durable but also custom-fitted to the needs of specific vessels. Additionally, these machines reduce the chances of defects, which can lead to costly repairs or replacements down the line.

Moreover, the investment in high-quality sewing machines also allows for more intricate designs and adaptations in sail production. Sailboats are often subject to various performance requirements based on different sailing conditions. Advanced sewing machines enable makers to incorporate features like reinforcements, windows, and unique shapes that optimize sail performance.

Maintenance and Upkeep

While sail cloth sewing machines are designed for durability, they still require regular maintenance to ensure longevity and optimum performance. This includes routine cleaning, lubrication, and occasional adjustments to the tension settings and feed systems. For many businesses involved in sail production and repair, having a dedicated technician for maintenance can minimize downtime and ensure that projects are completed within deadlines.

Conclusion

In conclusion, sail cloth sewing machines are indispensable tools within the marine industry. They not only facilitate the creation of high-quality sails that meet the demands of modern sailing but also contribute to the overall efficiency and precision of sail manufacturing. As the sailing community continues to grow, the evolution of sewing technology will undoubtedly play a significant role in advancing this segment of the marine industry, ensuring that sailors can rely on their sails for performance and safety on the open water.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025