Understanding the Functionality and Benefits of Saddle Stitch Machines in Modern Crafting

The Saddle Stitch Machine A Comprehensive Overview

In the world of leatherworking and bookbinding, precision and durability are paramount. One method that has stood the test of time for achieving strong, attractive seams is the saddle stitch. This technique, coupled with the right machinery, the saddle stitch machine, has transformed how artisans create leather goods and books.

What is Saddle Stitching?

Saddle stitching is a hand-sewn method that involves using two needles and a single length of thread. The stitch itself forms a distinctive pattern that is not only strong but also visually appealing, making it a favored choice for crafters and manufacturers alike. The elegance of the saddle stitch lies in its simplicity; each stitch creates a locking effect that provides durability, ensuring that seams can withstand stress and strain over time.

The Evolution of Saddle Stitch Machines

Historically, saddle stitching was a manual process that required skill and attention to detail. Craftspeople would painstakingly puncture holes in leather or paper, carefully guiding their needles to ensure an even finish. However, the introduction of saddle stitch machines has streamlined this process significantly. These machines combine technological advancements with traditional craftsmanship to produce high-quality stitched goods more efficiently.

Early saddle stitch machines were fairly rudimentary, essentially automating the hand-stitching process to some degree. Over the years, technology has advanced, and today's machines feature programmable settings, allowing for a variety of stitch lengths, tensions, and patterns. These innovations enable users to produce consistent results, minimizing the variance that often accompanies hand-sewn products.

Key Features of Saddle Stitch Machines

Modern saddle stitch machines come with a myriad of features designed to enhance usability and output quality. Here are some of the most notable aspects

1. Dual Needle System As saddle stitching requires two needles, most machines come equipped to handle this need seamlessly. This allows for the efficient execution of the stitch pattern, mirroring the quality of hand-stitched items.

2. Adjustable Stitch Length Depending on the application, the ability to modify stitch length is crucial. Whether for delicate bookbinding or robust leather bags, being able to adapt stitch size enhances the versatility of the machine.

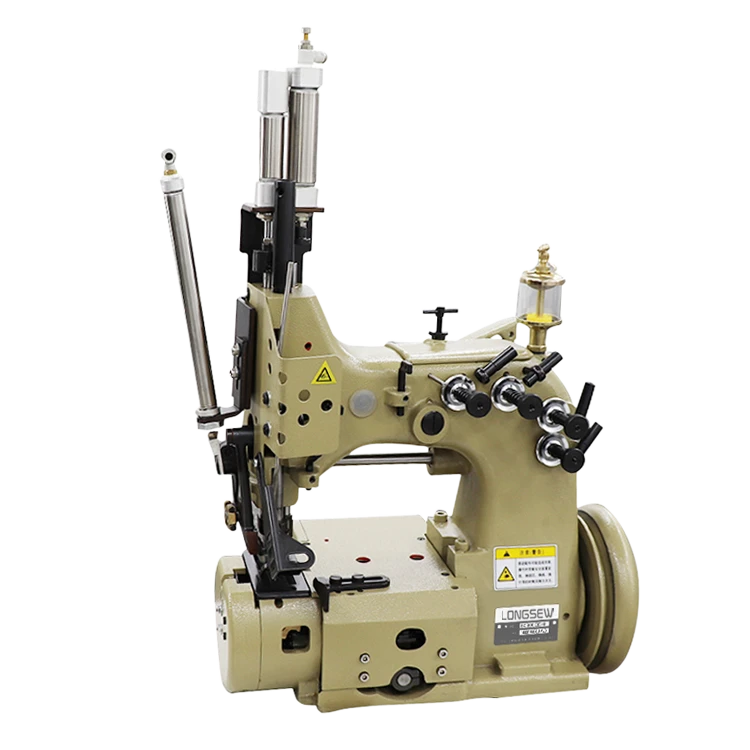

saddle stitch machine

3. Built-in Hole Puncher Many modern saddle stitch machines incorporate a hole-punching mechanism that pre-punches holes for the needles to pass through, ensuring uniform spacing and reducing prep time.

4. Heavy-Duty Construction Given that saddle stitch machines often work with tough materials like leather, they are built to endure the rigors of industrial sewing. Heavy frames and powerful motors ensure that they can handle thick materials with ease.

5. User-Friendly Controls Automation in sewing has led to the development of intuitive control panels that allow users to easily set up their stitching parameters and monitor the sewing process in real-time.

Applications of Saddle Stitch Machines

Industries utilizing saddle stitch machines span a wide spectrum. In leather goods manufacturing, applications include wallets, belts, handbags, and even shoes. The strength of the saddle stitch makes it particularly favorable for items that experience significant wear and tear.

In the world of bookbinding, saddle stitch machines are instrumental in producing notebooks, journals, and other stationery products. The aesthetic appeal of a saddle stitch also contributes to the overall design, making these products more marketable.

The Future of Saddle Stitch Machines

As sustainability becomes increasingly important in manufacturing, many saddle stitch machines are starting to incorporate eco-friendly technologies. Innovations in energy-efficient motors and the utilization of recycled materials are paving the way for more environmentally responsible production methods.

Furthermore, the integration of smart technology is poised to revolutionize the saddle stitch industry. Automated stitching patterns and real-time quality control are just the beginning as manufacturers strive to enhance productivity while maintaining craftsmanship.

Conclusion

The saddle stitch machine represents a harmonious blend of traditional techniques and modern technology, catering to the needs of diverse industries while upholding the quality and durability that saddle stitching is known for. As these machines evolve, they continue to play a crucial role in shaping the future of leatherworking and bookbinding, ensuring that artisans and manufacturers alike can produce beautiful, long-lasting products that meet the demands of consumers today. With each stitch, they not only create products but also maintain the rich heritage of craftsmanship that saddle stitching embodies.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025