pattern sewing machine for shoes

The Role of Pattern Sewing Machines in Shoe Production

In the world of footwear manufacturing, precision and efficiency are paramount. As consumer demands evolve and trends shift, the need for specialized equipment becomes increasingly important. One such innovation that has revolutionized the shoe production process is the pattern sewing machine. These machines not only enhance productivity but also improve the quality of the final product. In this article, we will explore the significance of pattern sewing machines in the production of shoes and their impact on the footwear industry.

Understanding Pattern Sewing Machines

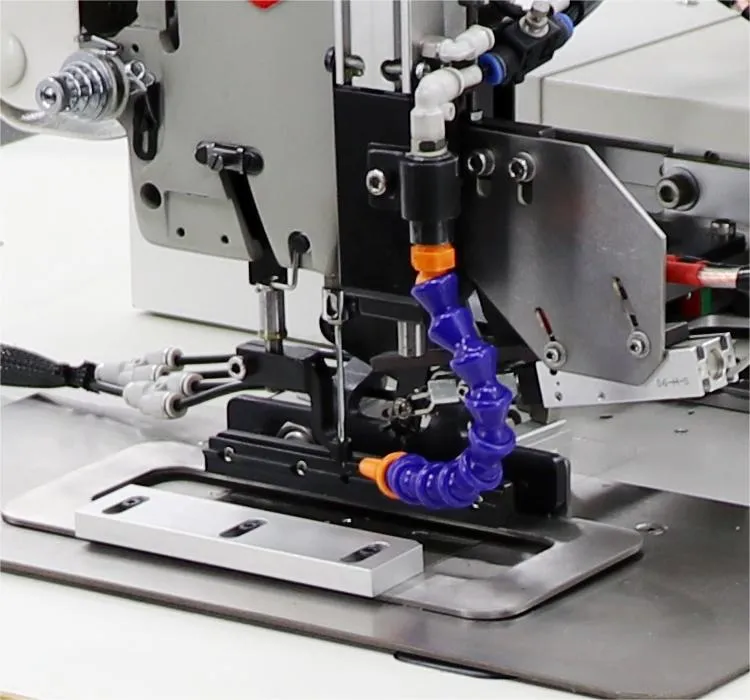

Pattern sewing machines are specialized devices designed to sew specific patterns into fabric or material. In the context of shoe manufacturing, these machines enable manufacturers to sew various components of a shoe with precision. They can handle complex designs and ensure that the seams are not only strong but also aesthetically pleasing. High-quality stitch patterns can enhance the durability of shoes while also making them visually appealing to consumers.

Efficiency in Production

One of the most significant advantages of using pattern sewing machines in shoe production is the increase in efficiency. These machines can operate much faster than manual sewing techniques, allowing manufacturers to produce a higher volume of shoes in a shorter amount of time. For instance, when a company receives a large order, pattern sewing machines can quickly adapt to different styles and sizes without significant downtime. This flexibility is crucial in an industry that often faces fluctuating demand and rapidly changing fashion trends.

Moreover, pattern sewing machines often come with automated features that minimize human error. Automation technology enables consistent stitch quality across large batches of shoes, ensuring that each product meets the brand’s quality standards. This level of reliability is essential, particularly for brands that seek to uphold their reputation for excellence.

Quality Control and Precision

pattern sewing machine for shoes

Quality control is a critical factor in shoe manufacturing. Consumers expect shoes not only to be stylish but also to withstand daily wear and tear. Pattern sewing machines contribute to this aspect of quality control by ensuring precise alignment of materials and even stitch distribution. This precision is vital for components like the upper, lining, and sole of the shoe, which must meet specific standards for both comfort and durability.

Additionally, pattern sewing machines offer the ability to create intricate designs that might be too complex for manual sewing. Brands can incorporate unique patterns and logos directly into the shoe design, adding a personal touch that appeals to a target market. This level of customization enhances the brand's image and can lead to increased customer loyalty.

Environmental Impact and Sustainability

As the footwear industry increasingly focuses on sustainability, pattern sewing machines play an integral role in reducing waste. Traditional sewing methods often lead to excess material waste due to inaccurate cuts and manual stitching errors. However, with the precision offered by pattern sewing machines, manufacturers can optimize the cutting process to ensure minimal waste. This efficiency not only benefits the environment but can also lead to cost savings for manufacturers.

Manufacturers can also explore eco-friendly materials, and pattern sewing machines can easily adapt to sewing these new materials. As more brands strive to create sustainable products, the versatility of pattern sewing machines becomes a valuable asset in the design and production of environmentally-friendly footwear.

Conclusion

In conclusion, pattern sewing machines have become an essential tool in the modern shoe manufacturing landscape. They enhance efficiency, ensure precise quality control, and contribute to sustainable production practices. As the demand for innovative and stylish footwear continues to grow, the role of pattern sewing machines will undoubtedly expand, shaping the future of the industry. Manufacturers that invest in these advanced machines are likely to stay competitive in an ever-evolving marketplace, ultimately benefiting both the business and the consumer. The footwear industry stands at the crossroads of fashion and technology, and pattern sewing machines are leading the way toward a more efficient, high-quality, and sustainable future in shoe production.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025