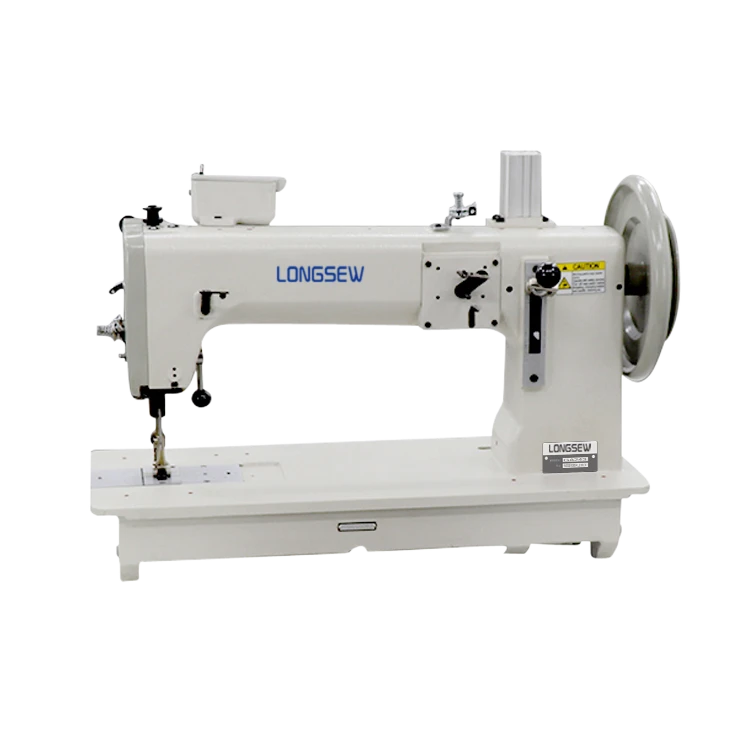

lock stitch sewing machine

Understanding Lock Stitch Sewing Machines

Lock stitch sewing machines have been an essential tool in the textile and fashion industries for many years. Whether you are a professional tailor, a fashion designer, or a sewing enthusiast, understanding how these machines work can significantly enhance your sewing experience and output. This article will provide an overview of lock stitch sewing machines, their features, and their applications.

At its core, a lock stitch sewing machine creates a basic stitch by interlocking two threads the upper thread and the bobbin thread. The upper thread is held on a spool, which is threaded through the machine's needle. The bobbin, located beneath the sewing bed, holds the lower thread. As the needle goes down, it pierces the fabric and wraps around the bobbin thread, effectively locking the two threads together. This process creates a secure and durable stitch, which is particularly important for clothing and upholstery.

One of the key advantages of lock stitch machines is their versatility. They can be used for a wide range of fabrics, from lightweight materials like chiffon to heavy-duty fabrics like denim or canvas. This adaptability makes them a favorite among seamstresses and garment manufacturers. Additionally, many lock stitch machines come with adjustable stitch lengths and widths, allowing users to customize their sewing projects according to individual requirements.

Lock stitch machines also contribute to the efficiency of the sewing process. Many modern models are equipped with features such as automatic needle threading, a built-in thread cutter, and adjustable presser feet. These enhancements streamline the sewing process and reduce the time taken for each project. Moreover, these machines can often handle multiple layers of fabric, which is essential for creating items like quilts or bags.

lock stitch sewing machine

In the realm of garment construction, lock stitch machines are commonly used for seam finishing, hems, and topstitching. The secure nature of the lock stitch makes it ideal for these applications, ensuring that garments are both durable and aesthetically pleasing. Furthermore, this type of stitch is less likely to unravel than other stitch types, providing added longevity to clothing items.

Lock stitch machines have evolved over the years, incorporating advanced technology that improves stitching quality and operational efficiency. Computerized lock stitch machines allow for precise control over stitching patterns, making them not only suitable for traditional sewing tasks but also for intricate designs that require accuracy. These machines often come with a range of built-in stitches, offering users creative versatility for decorative sewing.

While lock stitch machines are highly efficient and reliable, it is crucial for users to maintain them properly. Regular cleaning and lubrication are essential to keep the machine running smoothly. It is also important to use the correct type of thread and needle, as this can impact the stitch quality and overall performance of the machine.

In conclusion, lock stitch sewing machines play a vital role in the sewing industry, offering a combination of versatility, efficiency, and durability. Whether used for professional garment production or personal sewing projects, understanding their operation and maintenance can significantly improve the quality of your work. As technology continues to advance, these machines will undoubtedly continue to evolve, further enhancing their capabilities and applications in the world of sewing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025