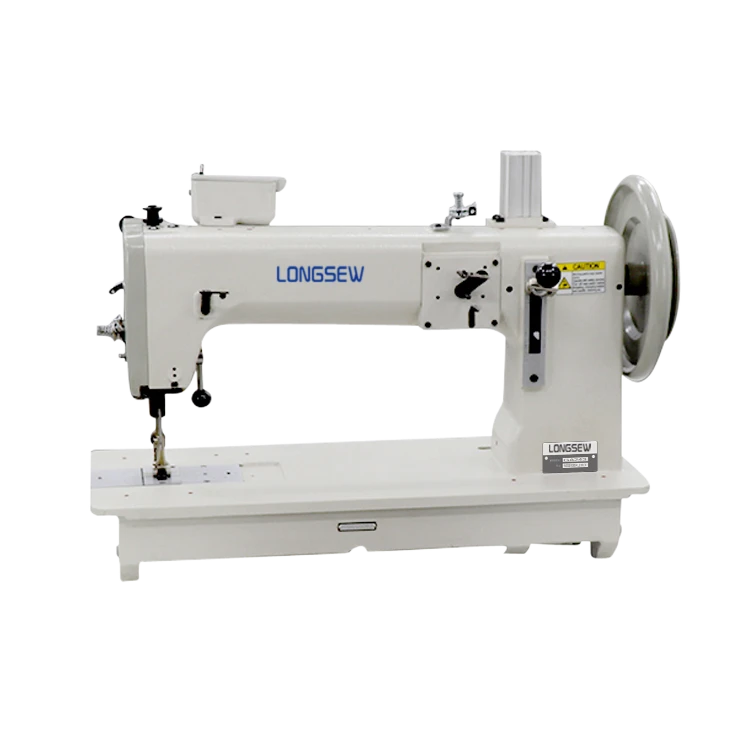

lock stitch sewing machine

The Lock Stitch Sewing Machine A Revolution in Textile Manufacturing

The lock stitch sewing machine is a cornerstone of the textile and garment industry, renowned for its efficiency and versatility. This innovative piece of machinery has transformed the way fabrics are joined together, enabling manufacturers to produce high-quality garments quickly and reliably. Understanding the lock stitch sewing machine's mechanics, applications, and evolution offers insight into its significance in modern textile manufacturing.

Mechanism of the Lock Stitch

At the heart of the lock stitch sewing machine is the unique mechanism that creates the interlocking stitches essential for strong seams. This machine utilizes two threads the top thread (needle thread) and the bottom thread (bobbin thread). When the needle penetrates the fabric, it loops the top thread around the bottom thread, forming a lock stitch. This design not only creates robust seams but also minimizes the risk of unraveling, ensuring that garments maintain their integrity through wear and wash.

The simplicity of the lock stitch mechanism is one of its greatest strengths. It can be operated at high speeds, allowing for rapid production without sacrificing quality. Additionally, the stitch is characterized by its even tension across the seam, making it desirable for many types of textiles, including lightweight fabrics and heavier materials like denim.

Versatility in Applications

The lock stitch sewing machine is versatile and can be employed across various applications in the textile industry. From the production of garments to upholstery and industrial textile products, this machine can handle multiple sewing requirements. Its adaptability makes it a preferred choice for manufacturers, enabling them to meet different design and construction needs efficiently.

Lock stitch sewing machines are used extensively in apparel manufacturing, from T-shirts to tailored suits. The ability to create various stitch types—such as straight, zigzag, and decorative stitches—enhances their usability. Moreover, with advancements in technology, modern lock stitch machines can be equipped with computerized controls, enabling precise stitch regulation, automated pattern sewing, and integration with CAD design systems, further expanding their capabilities.

lock stitch sewing machine

Evolution and Innovations

The lock stitch sewing machine has undergone significant evolution since its inception in the mid-19th century. The first practical lock stitch sewing machine was patented by Elias Howe in 1846, followed by Isaac Merritt Singer's improvements, which made sewing machines more accessible to the public. These early machines were hand-operated, but advancements in engineering eventually led to the creation of electric versions, revolutionizing production speed and efficiency.

In recent years, technological innovations, such as the introduction of robotic sewing systems and computer-aided manufacturing processes, have begun to reshape the landscape of textile manufacturing. These advancements allow for greater precision and quality control, reducing human error and increasing production efficiency. Automation in the sewing process has enhanced the capabilities of lock stitch machines, enabling manufacturers to produce complex garments with intricate designs without compromising on speed or accuracy.

Environmental Considerations

As the textile industry faces increasing scrutiny regarding environmental sustainability, the lock stitch sewing machine is also being adapted to meet these challenges. Manufacturers are now exploring eco-friendly sewing practices by incorporating sustainable materials and energy-efficient machinery into their production processes. The ability to efficiently use fabric and reduce waste during the sewing process is becoming increasingly important, with lock stitch machines playing a crucial role in minimizing excess material usage.

Conclusion

The lock stitch sewing machine remains a fundamental tool in textile manufacturing, combining simplicity, reliability, and versatility. Its ability to create durable seams has made it indispensable for garment production and various applications in the industry. With ongoing innovations and a focus on sustainability, the lock stitch sewing machine is poised to continue evolving, ensuring its relevance in a rapidly changing market. As the industry moves forward, this remarkable piece of technology will undoubtedly play a critical role in shaping the future of textile manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025