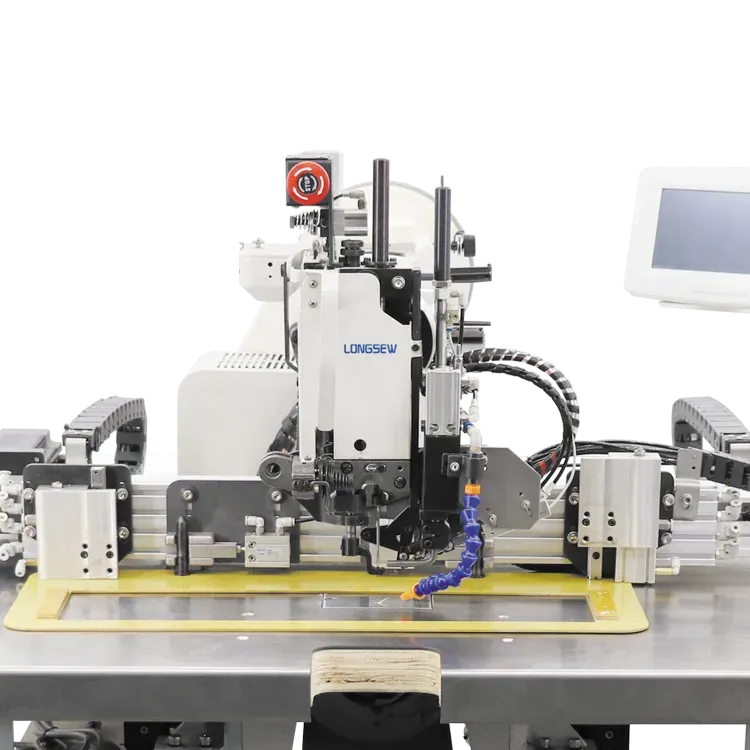

leather glove sewing machine

The Art and Craft of Sewing Leather Gloves The Role of Sewing Machines

Leather gloves have long been a symbol of elegance, craftsmanship, and durability. Whether for fashion, warmth, or protection, the process of creating leather gloves is an intricate art that requires precision, skill, and the right tools—especially sewing machines. As the demand for high-quality leather gloves rises, specialized sewing machines tailored for this purpose have become essential in the glove-making industry.

Sewing leather is not as straightforward as sewing cotton or polyester fabrics. Leather, being a natural material, has unique properties such as density, texture, and elasticity. A standard sewing machine may struggle with leather, often causing issues like skipped stitches, thread breakage, or uneven seams. This is where specialized leather glove sewing machines come into play. These machines are designed with robust motors and strengthened needles that can handle the thickness and toughness of leather while ensuring smooth and consistent stitching.

One of the critical features of sewing machines used for leather glove production is the walking foot mechanism. This mechanism allows the needle to work in conjunction with the feed dogs, enabling them to move together while working through multiple layers of material. This synchronized movement ensures even feeding and minimizes the risk of puckering or misalignment, which is crucial for creating gloves that fit perfectly.

Moreover, leather glove sewing machines often have adjustable stitch lengths and widths, allowing artisans to tailor their stitching to the specific requirements of each glove design. For example, a shorter stitch length might be preferred for areas that need more strength, while a longer stitch may be suitable for decorative elements. This flexibility enables manufacturers to create both functional and aesthetically pleasing products.

leather glove sewing machine

The importance of precision in glove-making cannot be overstated. Each glove must be cut meticulously to ensure that the fingers fit comfortably and allow for dexterity. The sewing machine, therefore, becomes an extension of the craftsman’s hand. With the right machine, skilled artisans can execute intricate patterns and details, from stitching down the seams to adding embellishments that enhance the glove’s appeal.

In addition to traditional methods, modern technology has introduced automated sewing machines capable of performing complex tasks without constant supervision. These machines can boost production rates and ensure consistency, making them an attractive option for larger manufacturers. However, the human touch remains irreplaceable in high-end, custom glove-making, where artisans still rely on manual sewing techniques to produce exquisite, one-of-a-kind pieces.

Sewing leather gloves is not just about stitching; it represents a blend of art and technology. The right sewing machines empower craftsmen to push the boundaries of design while maintaining the quality and durability that leather is known for. As fashion trends evolve, the role of sewing machines in leather glove production will continue to be crucial, shaping the future of this timeless accessory.

In conclusion, leather glove sewing machines play a vital role in preserving the artistry and craftsmanship associated with glove-making. Whether for fashion houses or local artisans, these machines enable the creation of leather gloves that are not only functional but also a true reflection of the craftsman's skill and creativity.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025