Efficient Sewing Solutions for Jumbo Bags in Industrial Applications

The Importance of Jumbo Bag Loop Sewing Machines in Modern Manufacturing

In the realm of manufacturing, efficiency and precision are paramount. As industries continue to evolve, the demand for robust, reliable machinery increases. One area that has seen significant advancements is in the production of jumbo bags, specifically pertaining to the sewing processes involved. Jumbo bag loop sewing machines play an indispensable role in ensuring that these bags—used extensively for packaging bulk materials—are constructed with the durability and quality required for demanding applications.

Understanding Jumbo Bags

Before delving into the machinery that produces them, it’s essential to understand what jumbo bags are. Also known as FIBCs (Flexible Intermediate Bulk Containers), jumbo bags are large, durable bags designed to transport and store dry bulk materials. They are widely used across various industries, including agriculture, construction, and chemicals, due to their ability to hold significant quantities—often over a ton—while being lightweight and cost-effective.

The Role of Loop Sewing Machines

Jumbo bag loop sewing machines are specifically designed to handle the unique requirements of sewing these large bags. These machines utilize advanced technology to ensure precise stitching, which is critical for maintaining the integrity of the bags. The loops sewn into the bags are essential for lifting and securing them during transportation. Therefore, the strength of these seams directly affects the safety and reliability of the bags.

Key Features of Jumbo Bag Loop Sewing Machines

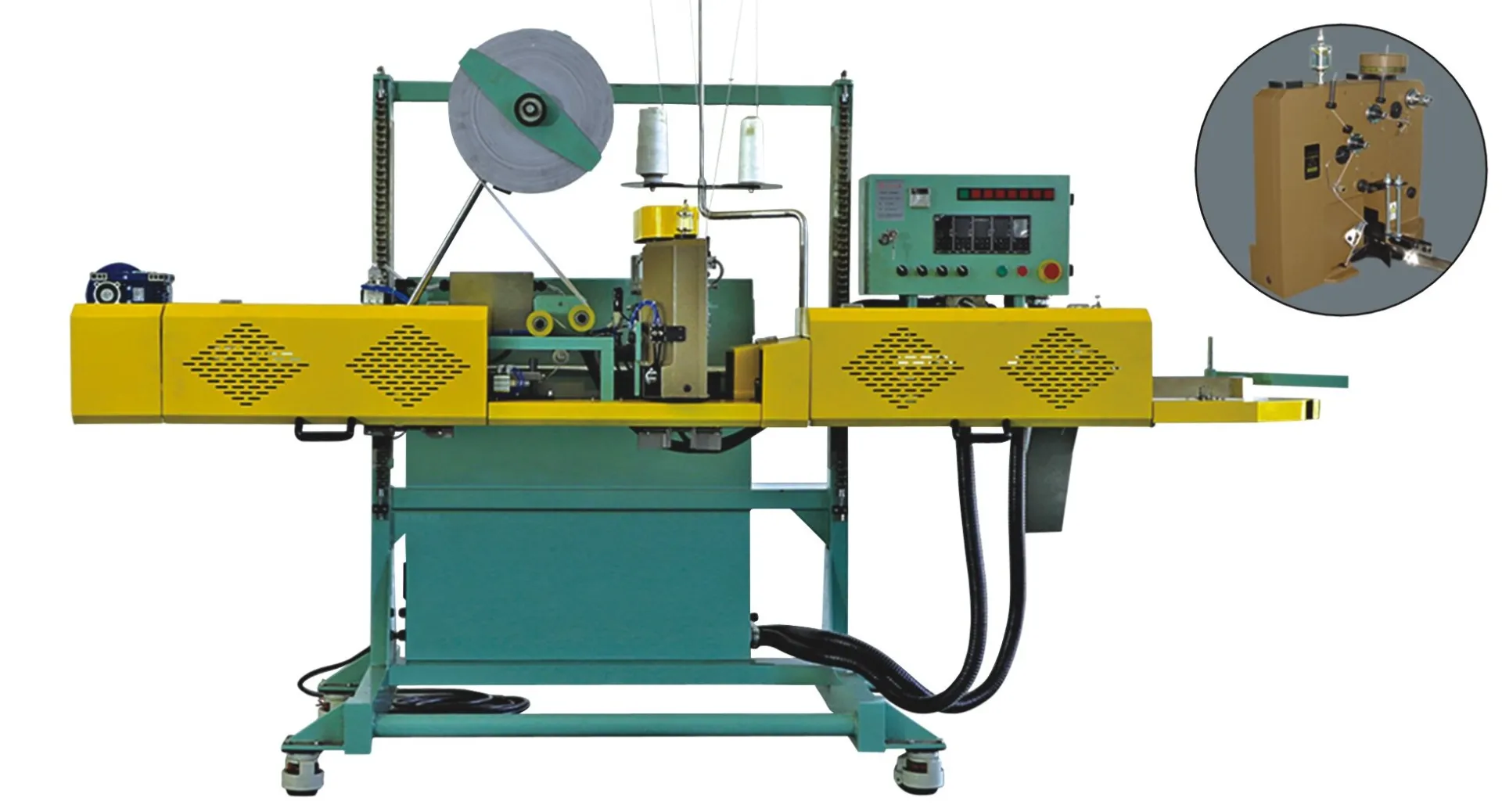

1. Heavy-duty Construction Jumbo bag loop sewing machines are built to withstand the rigors of sewing heavy materials. They feature sturdy frames and components that resist wear and tear, ensuring a long lifespan.

2. High Speed and Efficiency These machines operate at high speeds, significantly increasing production output. Efficiency is crucial in manufacturing where time is money, and the ability to produce more bags quickly can lead to substantial cost savings.

jumbo bag loop sewing machine

3. Precision Engineering Accurate stitching is vital for the performance of jumbo bags. Loop sewing machines are designed to deliver consistent stitch quality, minimizing the risk of failures due to seam splitting or unraveling.

4. User-Friendly Controls Modern machines often come with intuitive controls and automation features, allowing operators to set parameters quickly and adjust for different bag designs. This adaptability enhances productivity as manufacturers can switch between various bag styles without extensive downtime.

5. Safety Features Given the weight of the materials involved, safety is always a concern in manufacturing environments. Advanced loop sewing machines are designed with safety mechanisms to protect operators from accidents during operation.

The Impact on Industry

The integration of jumbo bag loop sewing machines into manufacturing processes has had a transformative effect on various sectors. For instance, in the agricultural industry, the ability to efficiently package fertilizers and seeds in durable bags translates to reduced waste and enhanced product delivery. In the construction sector, these machines ensure that materials like sand and gravel are securely packaged, minimizing spillage and loss during transport.

Additionally, with growing environmental concerns, many manufacturers are looking to produce biodegradable or recyclable jumbo bags. Advanced sewing machines can accommodate these new materials, allowing companies to innovate and adhere to sustainable practices.

Conclusion

Jumbo bag loop sewing machines represent a critical component of modern manufacturing. As industries continue to expand and evolve, the need for efficient, reliable, and precise machinery will only grow. The role of these machines not only enhances productivity but also ensures that manufacturers can meet the demands of diverse markets with confidence. By investing in high-quality loop sewing machines, businesses can secure their operations, improve product quality, and drive growth in an increasingly competitive landscape.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025