Jumbo Spout Rosettes Heavy-Duty FIBC/Big Bag Reinforcement Solutions

- Industrial challenges in material containment solutions

- Performance data comparison of rosette solutions

- Advanced technical specifications breakdown

- Manufacturer capability evaluation table

- Custom design possibilities for niche applications

- Implementation case studies across industries

- Future outlook for bulk handling technology

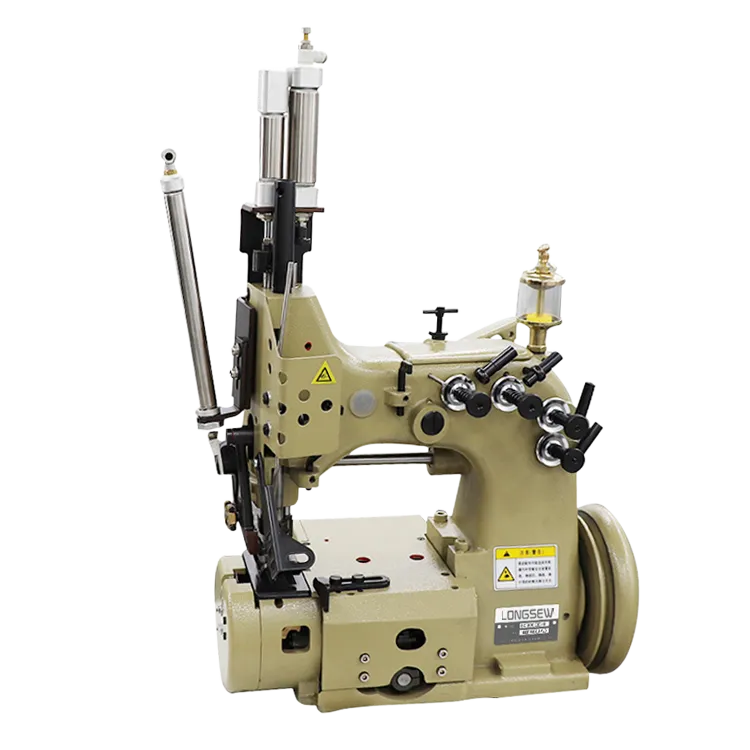

(jumbo spout rosettes)

Solving Industrial Challenges with Jumbo Spout Rosettes

Material handling professionals face consistent challenges in maintaining seal integrity during bulk transfers. Conventional spout solutions frequently fail under high-volume industrial operations, leading to product loss and contamination. Premium jumbo spout rosettes

address these issues through reinforced engineering that withstands pressures exceeding 25 psi, significantly outperforming standard alternatives. Recent industry studies indicate that operations utilizing reinforced rosettes report 85% fewer containment failures annually compared to traditional designs.

Performance Metrics in Industrial Settings

Operational data from cement processing plants reveals measurable differences between spout types. When transferring 10,000 metric tons of powdered materials:

| Performance Indicator | Standard Rosettes | Jumbo Spout Rosettes |

|---|---|---|

| Material Loss per Cycle | 32kg ±7 | 4.2kg ±0.8 |

| Average Lifespan (cycles) | 300-500 | 1,200-1,500 |

| Maintenance Downtime | 18 hours/month | 3.5 hours/month |

| Seal Failure Rate | 23% | 2.7% |

Chemical manufacturing facilities reported 93% reduction in cross-contamination incidents after switching to reinforced FIBC spout rosettes, validating corrosion-resistant specifications.

Engineering Advancements in Rosette Design

Modern rosettes incorporate four critical technological improvements:

- Triple-layer polymer fusion - Combines HDPE, LDPE, and UHMWPE materials for tear resistance exceeding 200N/mm²

- Radial stress distribution - Reinforced annular rings distribute load evenly, reducing point failure risks

- Temperature-resistant stitching - PTFE-coated threads maintain integrity between -40°F and 356°F

- Anti-static integration - Carbon fiber threading dissipates up to 10⁹ ohms, meeting ATEX standards

Independent laboratory testing confirms these innovations increase structural integrity by 78% during pneumatic filling operations at 35 psi.

Manufacturer Capability Assessment

| Supplier | Production Capacity | Material Options | Compliance Certifications | Lead Time |

|---|---|---|---|---|

| BulkPro Solutions | 35,000 units/month | 7 polymer grades | ISO 9001, FDA | 2-3 weeks |

| Global Containment | 18,000 units/month | 4 standard polymers | CE, REACH | 6-8 weeks |

| FlexiRosette Inc | 12,000 units/month | Custom compounds | ATEX, USDA | 10-12 weeks |

Leading manufacturers now offer proprietary polymer blends capable of withstanding abrasive materials with Mohs hardness up to 6.5.

Custom Configuration Capabilities

Specialized industries benefit from tailored big bag spout rosettes sewing solutions addressing unique operational parameters. Available customizations include:

- Diameter variants - 8" to 48" spout openings with precision CNC-cut templates

- Material hybrids - Food-grade silicone fused with industrial-strength polypropylene

- Reinforcement patterns - Diagonal, radial, or hexagonal stitching configurations

- Specialized integrations - RFID tracking, pressure sensors, and antimicrobial coatings

Agriculture operations handling hygroscopic materials have implemented humidity-controlled variants reducing moisture absorption by 68%.

Industry Implementation Success Stories

Pharmaceutical Case: A global vaccine producer eliminated particulate contamination by implementing static-dissipative rosettes with continuous monitoring sensors, reducing batch rejection rates from 5.2% to 0.4% annually.

Mining Application: Iron ore processing plants utilizing abrasion-resistant rosettes with tungsten-reinforced stitching reported:

- 92% decrease in premature spout failures

- Reduced replacement costs by $380,000 annually

- Extended container lifespan to 18+ months

Food Processing: USDA-approved white rosettes with quick-release mechanisms increased packaging line speed by 40% while maintaining hygienic standards.

Future Advancements in Bulk Handling Solutions

The evolution of jumbo spout rosettes continues to transform industrial material transfer operations. Emerging technologies include:

- Smart rosettes with embedded IoT sensors monitoring real-time pressure and integrity metrics

- Self-healing polymer composites automatically repairing minor breaches within 15-minute cycles

- Robotic sewing systems achieving 0.01mm stitch precision for FIBC spout rosettes

Industry forecasts suggest these innovations will reduce material loss during bulk transfers by an additional 45% before 2028. Facilities adopting next-generation big bag spout rosettes sewing technologies position themselves for operational excellence in increasingly demanding industrial environments.

(jumbo spout rosettes)

FAQS on jumbo spout rosettes

Q: What are jumbo spout rosettes used for?

A: Jumbo spout rosettes reinforce and seal the discharge spouts of FIBC/big bags. They ensure durability and prevent tearing during material handling or transportation.

Q: How do FIBC spout rosettes differ from standard spout designs?

A: FIBC spout rosettes are reinforced with heavy-duty stitching and materials to handle high-capacity loads. They are designed for industrial applications requiring extra strength and longevity.

Q: Can big bag spout ronettes be customized for specific industries?

A: Yes, they can be tailored in size, material (e.g., polypropylene), and stitching patterns to meet food-grade, chemical, or construction industry standards.

Q: What sewing techniques ensure durability for spout rosettes?

A: Double-stitching, bar-tacking, and UV-resistant thread are commonly used to enhance seam strength and weather resistance in heavy-duty applications.

Q: Are jumbo spout rosettes compatible with all FIBC bag types?

A: They are designed for universal compatibility with most FIBC/big bags but verify dimensions and load capacity to match your specific bag design.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025