Innovative Solutions for FIBC Bag Production with High-Quality Sewing Machines and Technology

The Importance of FIBC Sewing Machines in the Packaging Industry

In the modern packaging industry, the demand for efficient and reliable manufacturing processes has never been higher. One critical component of this sector is the FIBC (Flexible Intermediate Bulk Container), commonly known as bulk bags. These large, durable bags are designed to transport a variety of materials, from granules to powders, and they have become indispensable in sectors ranging from agriculture to construction. The production of these bags heavily relies on specialized machinery, with FIBC sewing machines playing a pivotal role.

The Importance of FIBC Sewing Machines in the Packaging Industry

One of the main features of FIBC sewing machines is their ability to create strong, secure seams. The integrity of an FIBC relies on its seams, which must be robust enough to hold heavy loads without tearing or ripping. This is particularly crucial in industries where safety and reliability are paramount. For instance, in the chemical industry, improperly sewn bags can lead to product loss or contamination, which can have serious financial and environmental repercussions. FIBC sewing machines are designed with specialized stitching techniques, such as double stitching and reinforced seams, to address these concerns.

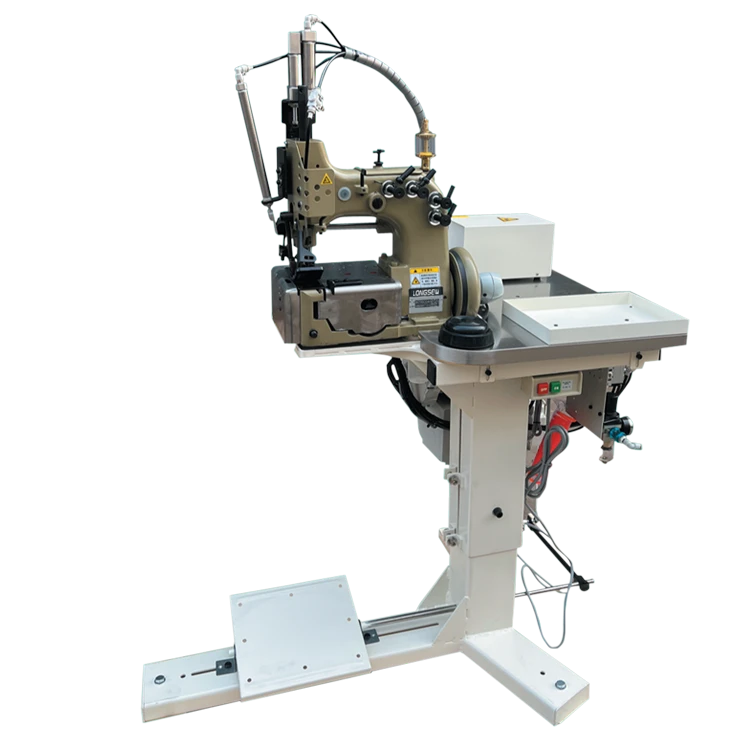

fibc sewing machine

Moreover, FIBC sewing machines are often equipped with advanced technology that enhances productivity and quality control. Automation features, such as programmable controls and automatic thread trimming, streamline the sewing process, reducing production times and labor costs. Additionally, many modern machines come with sensors that detect discrepancies or defects in the stitching, allowing operators to make real-time adjustments and maintain high quality standards.

The versatility of FIBC sewing machines is another significant advantage. These machines can be adapted to produce a variety of bag sizes and styles, catering to the diverse needs of different industries. From standard bulk bags to specialized designs with multiple fill and discharge options, the flexibility of FIBC sewing machines ensures that manufacturers can meet specific customer requirements efficiently.

Furthermore, the rise of sustainability in manufacturing has led to the development of eco-friendly FIBC options, further driving the innovation of FIBC sewing machines. Many manufacturers are exploring biodegradable and recyclable materials, necessitating sewing machines that can handle these new types of fabrics without compromising on the quality and strength of the seams. This evolution reflects the industry's commitment to sustainable practices and responsiveness to market demands.

In conclusion, FIBC sewing machines are integral to the successful production of bulk bags, directly impacting the packaging industry’s efficiency, quality, and sustainability. As the demand for FIBCs continues to grow, driven by global trade and the need for safe, effective storage solutions, the importance of investing in advanced sewing technology cannot be overstated. Manufacturers who recognize and embrace the capabilities of FIBC sewing machines are better positioned to thrive in an increasingly competitive marketplace, ensuring product safety and customer satisfaction while also aligning with sustainable practices. The future of bulk bag manufacturing lies in the hands of these specialized machines, which continue to evolve, setting new standards in the industry.

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025

-

Revolutionizing Efficiency with Automatic Sewing MachinesNewsMar.28,2025

-

Mastering Precision with Sewing Machines and ToolsNewsMar.28,2025

-

Mastering Precision with Double Needle and Chain Stitch Sewing MachinesNewsMar.28,2025

-

Leather Sewing Machines for Every NeedNewsMar.28,2025

-

Find the Best Deals on the Adler 205 370 Sewing MachineNewsMar.28,2025

-

The Essential Guide to Overlock Sewing MachinesNewsMar.18,2025