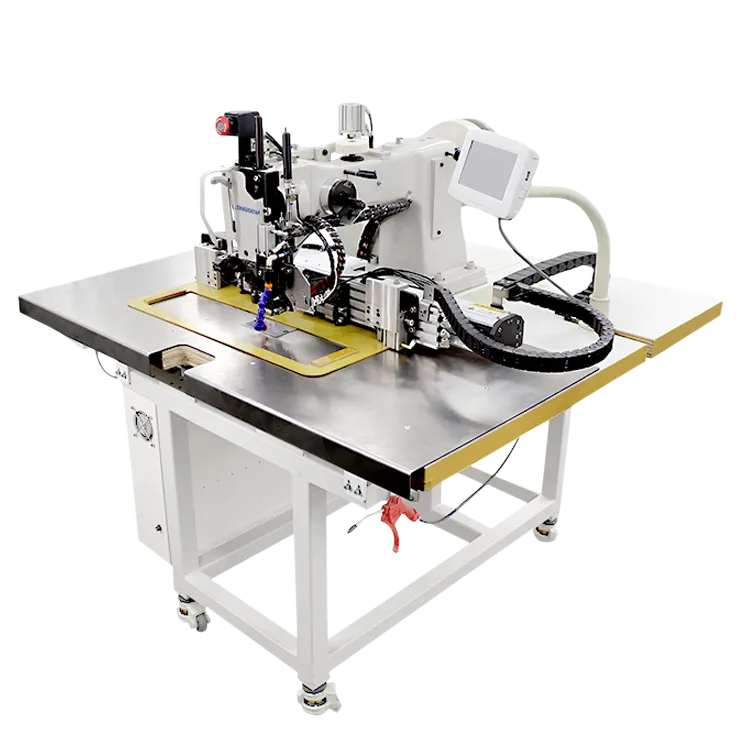

industrial walking foot sewing machine

The Industrial Walking Foot Sewing Machine Revolutionizing Fabric Handling

In the realm of industrial sewing, the walking foot sewing machine holds a pivotal role, especially in the production of heavy fabrics and intricate materials. This versatile machine is engineered to improve fabric handling and achieve precise stitches in various layered seam applications. Its unique design sets it apart from conventional machines, addressing the challenges posed by thicker and slippery materials such as leather, canvas, and multi-layered textiles.

Understanding the Walking Foot Mechanism

The core feature of a walking foot sewing machine is its walking foot mechanism. Unlike standard sewing machines, where the presser foot only holds the fabric from above, the walking foot also moves the fabric from below. This synchronized movement of the needle and foot ensures that multiple layers of fabric feed evenly through the machine, preventing puckering and misalignment. A walking foot is particularly beneficial when working with materials that lack grip, as it minimizes slippage and allows for consistent stitch formation.

Applications in Various Industries

The industrial walking foot sewing machines are widely used across several sectors. In the textile industry, they are indispensable for sewing upholstery fabrics, which must bear heavy use and require durability. In the leather goods sector, these machines excel at crafting items like bags, belts, and shoes, where precision and strength are paramount. The garment manufacturing industry also utilizes walking foot machines for constructing layered garments, where different materials are often combined.

In addition to these applications, walking foot machines are increasingly finding their way into the production of outdoor gear, such as tents, awnings, and tarps. The heavy-duty nature of these machines allows them to handle the thick threads and robust materials required in such environments, ensuring longevity and resilience against weather conditions.

Advantages Over Traditional Sewing Machines

1. Improved Fabric Feed The most significant advantage of a walking foot sewing machine is its ability to feed materials smoothly. This is essential when dealing with multiple layers or varied textures, which are common in heavy-duty sewing tasks.

industrial walking foot sewing machine

2. Precision Stitching The synchronized movement of the walking foot minimizes unintentional shifting of fabric, resulting in more accurate and uniform stitches. This precision is crucial in industries where quality is non-negotiable.

3. Versatility Walking foot machines are compatible with various materials, making them a versatile choice for manufacturers. Whether working with thick leather or delicate fabrics, these machines can adapt to ensure quality outcomes.

4. Durability Constructed with heavy-duty components, walking foot sewing machines are built to withstand the demands of industrial use. They can operate continuously and under rigorous conditions, making them a valuable asset for any manufacturing environment.

5. Multi-functionality Many modern walking foot sewing machines come equipped with additional features, such as adjustable stitch lengths, differential feed, and the ability to switch between straight and zigzag stitching. This multi-functionality enhances their utility across different sewing projects.

Challenges and Considerations

Despite their many advantages, walking foot sewing machines are not without challenges. They typically require a higher initial investment compared to standard sewing machines, which can be a barrier for smaller businesses. Additionally, proper training is essential to maximize their potential, as the nuances of operating a walking foot machine can differ significantly from traditional sewing equipment.

Maintenance is another crucial aspect, as these machines require regular attention to ensure optimal performance. Keeping the walking foot and needle in good condition is essential to prevent issues that could affect sewing accuracy.

Conclusion

The industrial walking foot sewing machine has revolutionized the way heavy fabrics are sewn, providing solutions to challenges faced by manufacturers across various industries. Its ability to handle multiple layers and maintain precision has made it a staple in the sewing landscape. As technology advances and demands in the textile industry evolve, the walking foot machine is likely to remain an essential tool, driving innovation and quality in fabric production. For businesses aiming to enhance their sewing capabilities, investing in a walking foot sewing machine can undoubtedly prove to be a wise and beneficial choice.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025