Ιαν . 23, 2025 02:54

Back to list

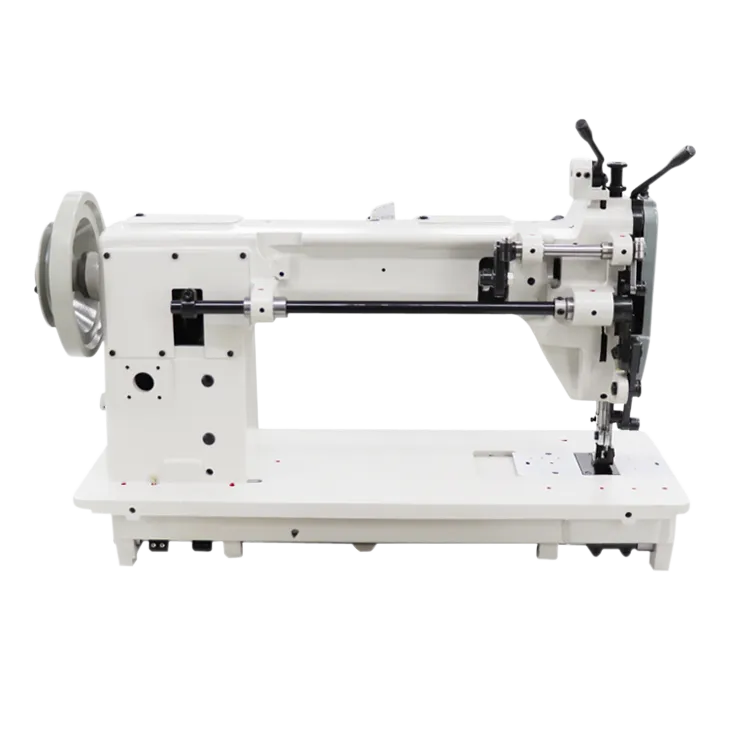

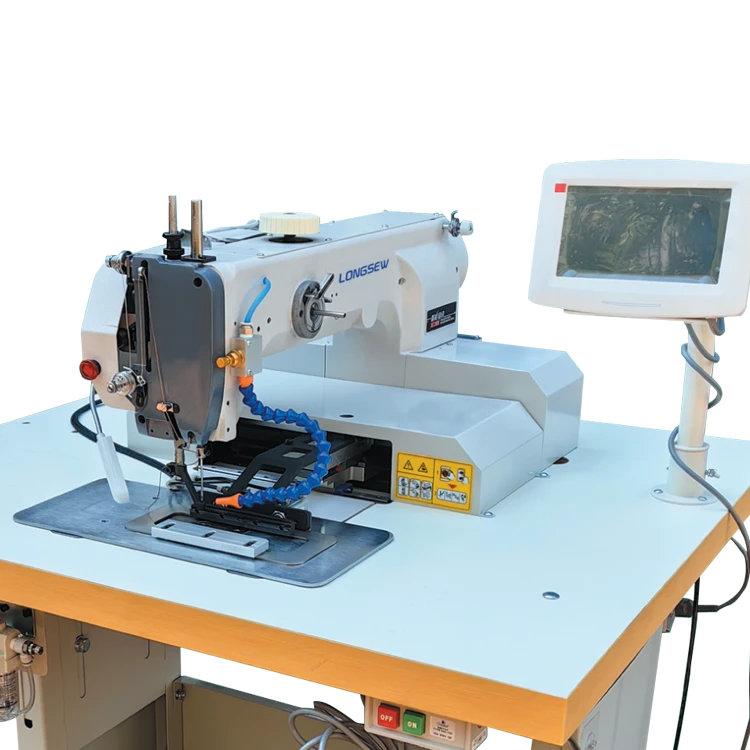

heavy duty sewing machine motor

A heavy-duty sewing machine motor is a critical component for anyone serious about sewing larger projects or working with heavy fabrics. Having spent years in the sewing industry, I've witnessed the significant difference a high-quality motor brings to the table. Not only does it enhance the sewing experience, but it also extends the durability of your machine, allowing you to tackle a wide range of materials with confidence.

Furthermore, ease of maintenance is a vital consideration. Heavy-duty sewing machine motors that allow for easy access for cleaning and occasional lubrication can make a significant difference in longevity and performance. In my professional journey, I once dealt with a motor that required specialized tools and considerable time just to perform basic maintenance. It was a lesson learned; a user-friendly design can save a lot of time and resources over the years. In terms of authority and trust, it's beneficial to be aware of expert opinions and consumer reviews. Consult online sewing communities, forums, or even a trusted sewing machine dealer. Their insights often come from hands-on experience with various models and can provide valuable guidance. Once, a recommendation from a seasoned tailor led me to a high-torque motor model that has never let me down, proving the importance of expert advice. Price is another factor that needs careful assessment. While it might be tempting to go for the cheapest option, investing in a slightly higher-end motor often proves cost-effective in the long run. Quality motors tend to require less frequent replacements and are less likely to incur repair costs. I’ve personally found that spending a little more upfront saved me a considerable amount of money and hassle down the road. In conclusion, a heavy-duty sewing machine motor is an investment that can radically enhance both personal and professional sewing projects. Evaluating power, construction, noise levels, maintenance requirements, expert recommendations, and price can lead to a motor that enhances your sewing experience, provides durability, and ensures satisfaction. By choosing a reliable and sturdy motor, you are setting yourself up for success in any heavy-duty sewing project you decide to undertake.

Furthermore, ease of maintenance is a vital consideration. Heavy-duty sewing machine motors that allow for easy access for cleaning and occasional lubrication can make a significant difference in longevity and performance. In my professional journey, I once dealt with a motor that required specialized tools and considerable time just to perform basic maintenance. It was a lesson learned; a user-friendly design can save a lot of time and resources over the years. In terms of authority and trust, it's beneficial to be aware of expert opinions and consumer reviews. Consult online sewing communities, forums, or even a trusted sewing machine dealer. Their insights often come from hands-on experience with various models and can provide valuable guidance. Once, a recommendation from a seasoned tailor led me to a high-torque motor model that has never let me down, proving the importance of expert advice. Price is another factor that needs careful assessment. While it might be tempting to go for the cheapest option, investing in a slightly higher-end motor often proves cost-effective in the long run. Quality motors tend to require less frequent replacements and are less likely to incur repair costs. I’ve personally found that spending a little more upfront saved me a considerable amount of money and hassle down the road. In conclusion, a heavy-duty sewing machine motor is an investment that can radically enhance both personal and professional sewing projects. Evaluating power, construction, noise levels, maintenance requirements, expert recommendations, and price can lead to a motor that enhances your sewing experience, provides durability, and ensures satisfaction. By choosing a reliable and sturdy motor, you are setting yourself up for success in any heavy-duty sewing project you decide to undertake.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025