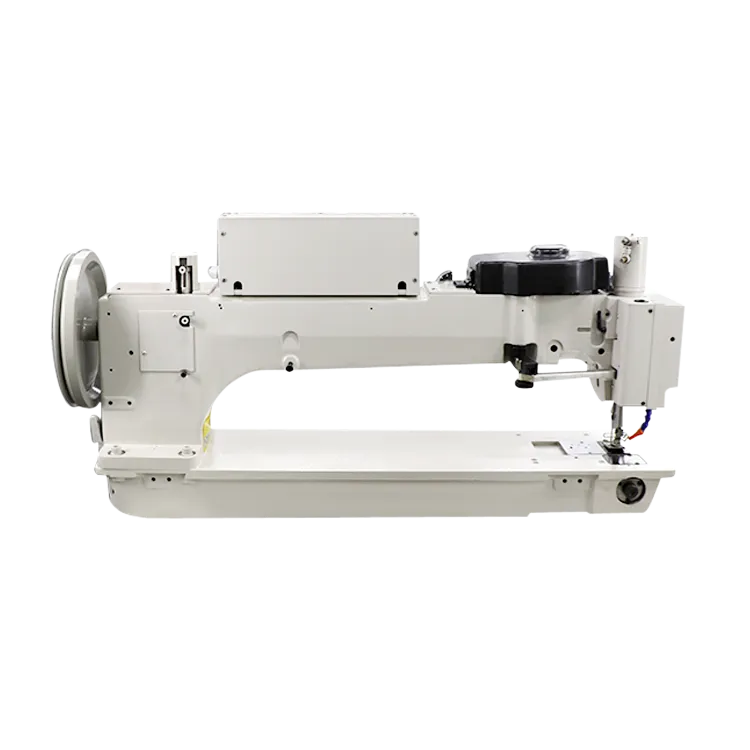

Durable Industrial Lock Stitch Sewing Machine for Heavy Fabrics and Professional Use

Understanding Heavy Duty Lock Stitch A Key Element in Industrial Sewing

In the world of sewing and garment manufacturing, the choice of stitch type can significantly influence the durability and aesthetic appeal of a finished product. Among the various types of stitches available, the heavy duty lock stitch stands out for its strength and versatility, making it a preferred choice in industrial applications.

What is a Lock Stitch?

A lock stitch is a type of stitch made by interlocking two threads one from the top (needle thread) and one from the bottom (bobbin thread). This mechanism constructs a tight, secure stitch that has a flat appearance on the surface of the fabric, which minimizes bulk and creates a clean finish. The heavy duty variant of the lock stitch is specifically designed for tough materials and heavy workloads, making it essential for industries that demand durability, such as upholstery, heavy garments, and canvas products.

Advantages of Heavy Duty Lock Stitch

1. Strength and Durability The primary advantage of the heavy duty lock stitch is its robust nature. The interlocking of threads creates a situation where the stitch can withstand significant tension and shear forces. This makes it ideal for items subjected to strain, such as work wear, outdoor gear, and automotive upholstery.

2. Compatibility with Heavy Materials While traditional sewing machines might struggle with thicker fabrics, heavy duty sewing machines equipped to use lock stitches can easily handle materials like leather, denim, and canvas. This capability broadens the applications of heavy duty lock stitches within various industries.

3. Enhanced Aesthetic Quality The lock stitch produces a neat and professional-looking finish. Since the stitch lies flat on the surface of the fabric, it minimizes the risk of fabric bunching or puckering, ensuring that the final product meets high aesthetic standards.

4. Versatility Heavy duty lock stitch machines can often handle a variety of tasks beyond simple stitching. They can create decorative stitches, sew seams, and perform buttonholes, making them a staple in factories and workshops.

heavy duty lock stitch

Applications of Heavy Duty Lock Stitch

The applications of heavy duty lock stitch technology are extensive. Industries that frequently utilize this stitch include

- Apparel Manufacturing Many industrial clothing manufacturers rely on heavy duty lock stitch for work uniforms, safety gear, and outdoor apparel that require durability. - Upholstery Furniture manufacturers often use heavy duty lock stitches to ensure that seams can withstand daily wear, especially in residential and commercial settings. - Automotive Industry From seat covers to interior linings, heavy duty lock stitches provide the necessary strength and longevity required in automotive applications.

- Outdoor Gear and Equipment Camping gear, backpacks, and tarps need to endure harsh conditions; heavy duty lock stitching guarantees that these products remain functional and intact.

Challenges and Considerations

While heavy duty lock stitches offer numerous benefits, sewing professionals must also be mindful of certain challenges. An incorrect tension setting can lead to issues such as thread breakage or uneven stitching. Additionally, the choice of thread type plays a critical role in the performance of the lock stitch; using threads that are too fine can compromise the stitch's integrity.

Conclusion

In summary, the heavy duty lock stitch is a vital component in various sewing applications where strength, durability, and aesthetics are paramount. Its ability to interlock threads securely allows manufacturers to produce high-quality products capable of resisting the rigors of everyday use. As industries continue to evolve and demand greater durability in their products, the relevance of the heavy duty lock stitch remains a central tenet in the field of industrial sewing. Understanding its benefits and applications will enable manufacturers and sewing professionals to make informed decisions about their stitching needs, thus enhancing the quality of their output.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025