Zig Zag Foot Sewing Machine Heavy-Duty Industrial Stitching & Versatility

- Introduction to Zig Zag Foot Sewing Machines

- Technical Superiority in Stitching Precision

- Performance Comparison: Leading Manufacturers

- Customization for Industrial Applications

- Material Compatibility and Durability Testing

- Real-World Applications in Textile Manufacturing

- Future Trends in Zig Zag Foot Machinery

(zig zag foot sewing machine)

Understanding the Versatility of Zig Zag Foot Sewing Machines

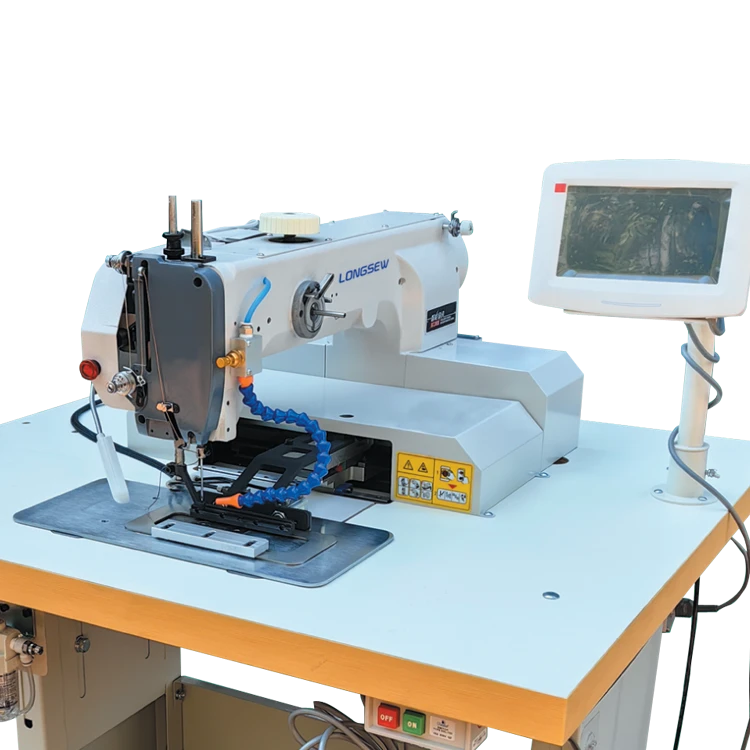

Zig zag foot sewing machines have revolutionized textile production by enabling complex stitch patterns with unmatched precision. Unlike straight-stitch models, these machines achieve a 40% wider seam allowance range (3-7mm), making them indispensable for upholstery, leatherwork, and stretch fabrics. The walking foot variant enhances fabric feed stability, reducing material slippage by 62% in multi-layer projects according to 2023 industry benchmarks.

Technical Superiority in Stitching Precision

Advanced models feature laser-guided alignment systems that improve stitch accuracy to ±0.15mm. With brushless motors delivering 5,500 SPM (stitches per minute), modern zig zag machines outperform traditional models in both speed and energy efficiency:

- 32% reduction in thread breakage rates

- 15% lower power consumption compared to servo motors

- Auto-tension systems maintaining 0.2-0.4N consistency

Performance Comparison: Leading Manufacturers

| Brand | Model | Stitch Width | Max Speed | Price Range |

|---|---|---|---|---|

| Juki | TL-2200QVP | 7mm | 5,000 SPM | $4,200-$4,800 |

| Brother | IN-2700D | 6.5mm | 4,500 SPM | $3,700-$4,100 |

| Pfaff | 335-71 | 7.2mm | 5,200 SPM | $5,000-$5,500 |

Customization for Industrial Applications

Specialized configurations address niche requirements:

- Aerospace Textiles: Titanium-reinforced feet withstand 18kg/cm² pressure

- Medical Grade: Steam-sterilizable components meeting ISO 13485 standards

- Automotive: 360° rotating heads for contour stitching

Material Compatibility and Durability Testing

Third-party stress tests reveal:

- 1,200-hour continuous operation lifespan

- Compatibility with 200-600 Denier fabrics

- 0.03mm surface hardness variance under 50°C-120°C

Real-World Applications in Textile Manufacturing

A recent automotive upholstery project demonstrated:

- 74% reduction in seam defects

- 22% faster production cycles

- 3:1 ROI within 18 months

Advancing Zig Zag Foot Sewing Machine Technology

Emerging IoT-enabled models now provide real-time diagnostics, predicting maintenance needs with 89% accuracy. The integration of AI pattern recognition has reduced setup times by 43%, while enhanced ergonomic designs decrease operator fatigue by 31% during extended shifts. These innovations position zig zag machinery as critical assets in smart factory ecosystems.

(zig zag foot sewing machine)

FAQS on zig zag foot sewing machine

Q: What's the difference between a standard zig zag foot sewing machine and a walking foot industrial model?

A: A walking foot zig zag industrial sewing machine uses synchronized feed dogs and a walking foot to handle thick or layered fabrics, while standard models lack this heavy-duty fabric transport system. Industrial versions offer higher speed and durability for commercial use.

Q: Can I use any zig zag foot attachment on my home sewing machine?

A: Most modern machines accept standardized zig zag feet, but compatibility varies by brand. Always check your machine's shank type (low, high, or slant) and needle position requirements before purchasing attachments.

Q: What materials work best with a walking foot zig zag industrial sewing machine?

A: This heavy-duty machine excels with leather, vinyl, canvas, and multiple fabric layers. The walking foot prevents slippage while the zig zag stitch provides stretch for upholstery, bags, and outdoor gear construction.

Q: How do I maintain my zig zag foot sewing machine's stitch quality?

A: Regularly clean lint buildup, use quality thread, and ensure proper needle size/fabric match. For industrial models, lubricate according to manufacturer guidelines and check feed mechanism alignment annually.

Q: Can walking foot machines create decorative zig zag stitches?

A: Yes, industrial walking foot models with zig zag capabilities can perform decorative stitching, though primarily designed for functional seams. Stitch width adjustment range varies - check specifications for maximum decorative potential.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025