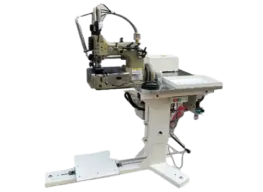

Versatile Electric Leather Sewing Machine for Professional Crafting and Repair Projects at Home and Beyond

Exploring Electric Leather Sewing Machines A Comprehensive Overview

In the realm of crafting leather goods, the right tools can make all the difference. Among these tools, electric leather sewing machines have emerged as indispensable allies for both amateur and professional artisans. These machines combine the power of automation with the precision required for leatherwork, leading to improved efficiency and creativity in the crafting process.

The Advantages of Electric Leather Sewing Machines

One of the primary benefits of electric leather sewing machines is their ability to handle various thicknesses and types of leather with ease. Traditional manual sewing machines may struggle with thicker materials, leading to inconsistent stitches or even damage to the machine. In contrast, electric machines are designed with powerful motors and specialized feed systems, enabling them to effortlessly stitch through multiple layers of leather, canvas, or other tough materials.

Another significant advantage is the speed at which work can be completed. Electric sewing machines often feature adjustable speed settings, allowing users to tailor their sewing speed to the intricacies of their project. For detailed work, a slower speed can provide the precision needed to navigate curves and corners, while a higher speed can enhance productivity for larger, more straightforward tasks. This versatility is crucial for leather crafters who might be producing everything from wallets to heavy-duty bags.

Features to Look For

electric leather sewing machine

When considering the purchase of an electric leather sewing machine, several key features should be taken into account. First, the type of motor is critical—industrial-grade motors offer greater torque and reliability, which is essential for continuing projects without interruptions. Additionally, needle and foot options greatly influence the machine’s performance. Leather-specific needles and walking feet can prevent slippage and create uniform stitches, making them ideal for leatherwork.

Adjustability is another factor to consider. Many electric machines allow users to customize stitch length and width, which is especially important for various leather types and project needs. Furthermore, automatic features, such as thread tension adjustment and reverse stitching capabilities, can enhance the sewing experience by reducing manual adjustments.

Maintenance and Care

Proper maintenance of electric leather sewing machines is vital to ensure their longevity and consistent performance. Regular cleaning to remove debris and dust, along with periodic lubrication of moving parts, can prevent malfunctions and maximize efficiency. It's also essential to choose the right type of thread and needles; using high-quality materials designed for leather will enhance stitch strength and durability.

Conclusion

Electric leather sewing machines represent a significant advancement in the world of leather crafting, merging technological efficiency with traditional techniques. For artisans looking to elevate their craft, investing in a quality electric sewing machine can unlock new possibilities, allowing for the creation of intricate and durable leather pieces. Whether crafting functional everyday items or unique bespoke designs, these machines offer a blend of speed, precision, and versatility that is hard to beat. As the leatherworking community continues to grow, embracing advancements in technology while honoring traditional skills will undoubtedly lead to a vibrant future filled with creativity and innovation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025