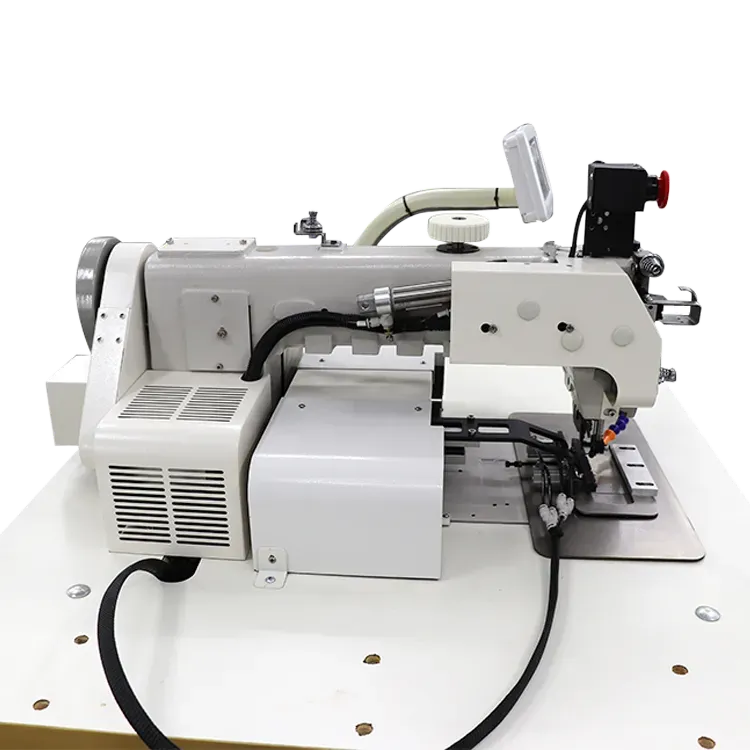

single needle ubt machine

The Single Needle UBT Machine A Revolution in Textiles

In the ever-evolving world of textile manufacturing, the introduction of advanced machinery plays a crucial role in enhancing productivity and quality. One notable innovation is the Single Needle UBT (Under Bed Trimmer) machine. This sophisticated piece of equipment has revolutionized sewing processes, providing manufacturers with unprecedented efficiency and precision.

Understanding the Single Needle UBT Machine

The Single Needle UBT machine is a specialized sewing machine designed for various applications, particularly in garment manufacturing. Its defining feature is the single needle mechanism, which offers enhanced control over the stitching process. Unlike multi-needle machines, the Single Needle UBT focuses on delivering high-quality seams with a significant reduction in fabric waste. The UBT function further enhances its capabilities by trimming excess fabric automatically, leading to cleaner finishes and less manual intervention.

Key Advantages

1. Precision and Control One of the main advantages of the Single Needle UBT machine is its ability to provide precise stitching. With a single needle, operators have better control over the sewing process, reducing the risk of errors that can arise from using multiple needles. This precise control is crucial for intricate designs and delicate fabrics, ensuring that every stitch is placed flawlessly.

2. Efficiency and Speed In today’s fast-paced textile industry, efficiency is paramount. The incorporation of the under bed trimmer allows for continuous sewing without the need for manual trimming, drastically reducing downtime and increasing overall productivity. Operators can complete tasks more quickly, allowing manufacturers to meet tight deadlines and increasing throughput in production lines.

3. Reduced Material Waste The UBT feature minimizes fabric waste during the sewing process. By trimming excess material automatically, the machine ensures that the fabric is utilized effectively, reducing costs associated with excess material disposal. This not only saves money but also aligns with sustainable practices by promoting environmentally-friendly manufacturing methods.

single needle ubt machine

4. Versatility The Single Needle UBT machine can handle a variety of fabric types, making it a versatile addition to any sewing workshop. Whether working with lightweight fabrics like chiffon or heavier materials like denim, the machine can be adjusted to cater to different textile needs. This adaptability makes it an essential tool for manufacturers who deal with diverse product lines.

5. Ease of Use and Maintenance Operators appreciate the straightforward design of the Single Needle UBT machine. Its user-friendly interface and simplified settings allow for easy adjustments, making it accessible even for those with limited sewing machine experience. Additionally, maintenance of the machine is relatively simple, with fewer components that require regular servicing compared to more complex multi-needle machines.

Applications in the Textile Industry

The Single Needle UBT machine is widely used in various segments of the textile industry. It is particularly beneficial in garment production, where high-quality seams are essential. From basic garments to intricate designs, the precision offered by this machine ensures that the final product meets high-quality standards.

Furthermore, in industries like upholstery and leather goods, where thick materials are often used, the Single Needle UBT machine excels due to its robust construction and capability to handle multiple layers of fabric without compromising on stitch quality.

Conclusion

In conclusion, the Single Needle UBT machine marks a significant advancement in textile manufacturing, combining precision, efficiency, and adaptability. For manufacturers aiming to improve their production processes, investing in such technology is essential. As the industry continues to evolve, the role of sophisticated machinery like the Single Needle UBT will undeniably be at the forefront of shaping the future of textile production.

With ongoing innovations, this machine exemplifies how technology can enhance traditional processes, ensuring that manufacturers remain competitive in a rapidly changing marketplace. As we look ahead, the Single Needle UBT machine stands as a testament to the importance of embracing technology for continued growth and excellence in the textile industry.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025