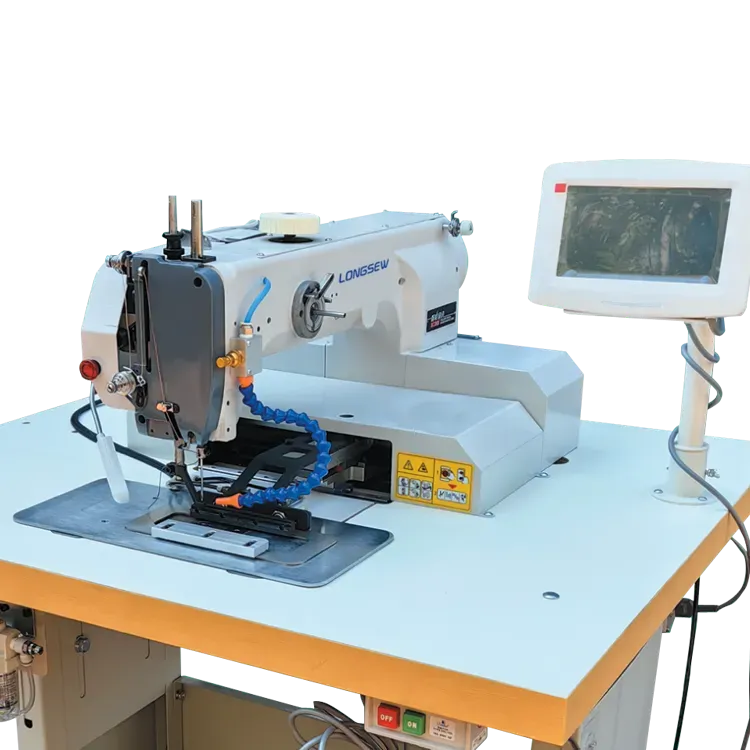

needle lockstitch machine

A Comprehensive Overview of the Needle Lockstitch Machine

The needle lockstitch machine holds a prominent place in the world of textile manufacturing and garment production. This machine, often referred to simply as a lockstitch machine, is a staple in both industrial and domestic sewing environments. Its design, functionality, and versatility have evolved significantly, making it an essential tool for seamstresses and manufacturers alike.

Understanding the Needle Lockstitch Mechanism

At its core, the needle lockstitch machine operates on a straightforward yet effective principle. The machine utilizes a single needle to create stitches by interlocking two threads the upper thread, wound around a spool, and the lower thread, usually a bobbin placed beneath the needle plate. As the needle pierces through the fabric, it carries the upper thread down, which then loops around the lower thread to form a secure stitch. The synchronized movement of the needle and the feed mechanism ensures consistent and precise stitching.

This mechanism is advantageous for various sewing applications, producing a tightly woven stitch that provides strength and durability. The lockstitch is particularly favored for seaming fabrics, making it ideal for a range of clothing, upholstery, and other textile products.

Types of Needle Lockstitch Machines

There are various types of needle lockstitch machines, each designed for specific applications. The most common include

1. Industrial Lockstitch Machines These are heavy-duty machines designed for high-volume production. They often come with additional features such as automatic thread trimmers and programmable controls to enhance efficiency.

2. Domestic Sewing Machines Tailored for home use, these machines vary in complexity and features. Many models offer built-in stitches and user-friendly controls, making them accessible for hobbyists and beginner seamstresses.

4. Flatbed vs. Cylinder Bed Flatbed machines are suitable for most sewing tasks. In contrast, cylinder bed machines are designed for sewing tubular items, like sleeves and cuffs, making them valuable in garment production.

needle lockstitch machine

Advantages of Needle Lockstitch Machines

The needle lockstitch machine offers numerous advantages that contribute to its widespread use

- Strength and Durability The lockstitch is renowned for creating strong seams that withstand stress and strain, making it particularly advantageous for heavy fabrics and items subjected to wear.

- Versatility This type of machine can be used on various fabrics, from lightweight materials like silk to heavier canvas and denim, broadening its utility in diverse sewing projects.

- Ease of Use Many needle lockstitch machines are designed with user-friendly features, making them accessible for both beginners and experienced users.

- Economic Efficiency In industrial settings, lockstitch machines contribute to streamlined production processes, reducing both time and labor costs with their fast stitching speeds.

Maintenance and Repair

To ensure optimal performance, regular maintenance of needle lockstitch machines is crucial. Common maintenance tasks include oiling moving parts, cleaning the bobbin case to prevent lint buildup, and checking the tension of both upper and lower threads. Furthermore, understanding common issues—such as thread breakage, skipped stitches, or fabric bunching—can empower users to troubleshoot effectively and prolong the machine's life.

Conclusion

In conclusion, the needle lockstitch machine is an indispensable tool in the textile industry, boasting a rich history and an unwavering relevance in today’s manufacturing landscape. Its design simplicity, coupled with its robust stitching capabilities, makes it a choice for diverse applications, from professional garment production to home-based sewing projects. As technology continues to evolve, the needle lockstitch machine remains a benchmark of quality and efficiency, ensuring that the art of sewing thrives in an ever-changing world. Whether for industrial use or personal creativity, the lockstitch machine continues to be a vital component in shaping fabrics into finished products that enrich our lives.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025