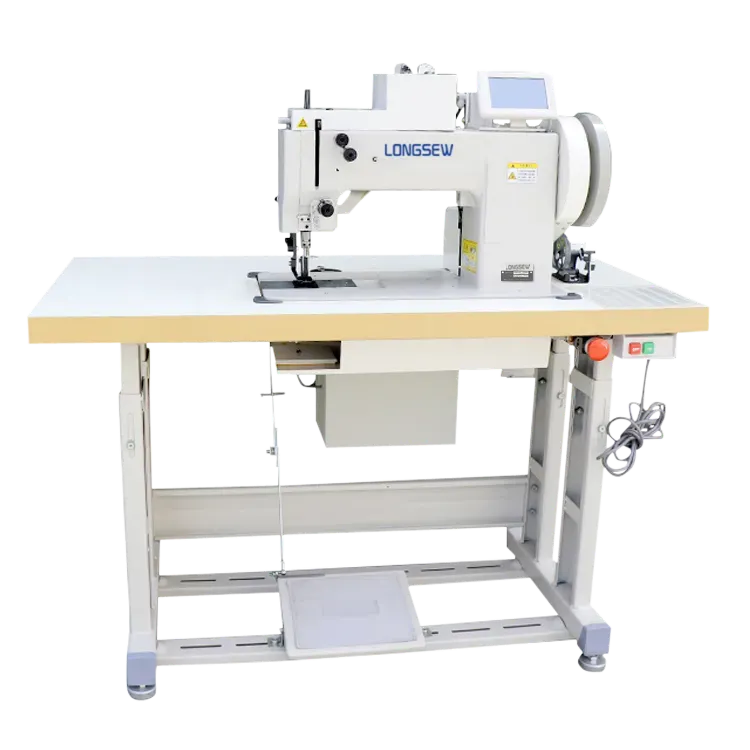

Motorized Chinese Leather Sewing Machine for Efficient Craftsmanship and Professional Results

The Rise of Motorized Chinese Leather Sewing Machines

The global leather industry has witnessed a significant transformation over the past few decades, largely due to advancements in technology and manufacturing processes. One of the most notable developments is the emergence of motorized leather sewing machines, particularly those produced in China. These machines have revolutionized the way leather goods are made, offering speed, precision, and efficiency that were previously unimaginable.

A Historical Perspective

Traditionally, leather sewing was a labor-intensive process that required skilled artisans to meticulously stitch leather by hand. While this method produced high-quality products, it was time-consuming and often limited the volume of production. As demand for leather goods surged, particularly in fashion and automotive industries, the need for faster, more efficient manufacturing solutions became apparent.

The introduction of motorized sewing machines in the mid-20th century marked a pivotal point in this evolution. At that time, Western countries led the charge with their advanced technology and manufacturing expertise. However, as the global economy began to shift, Asian countries, particularly China, emerged as powerhouses in manufacturing. Chinese companies quickly adapted and innovated, developing motorized leather sewing machines that catered specifically to the needs of a growing market.

Features of Motorized Chinese Leather Sewing Machines

Motorized leather sewing machines made in China are equipped with numerous features that enhance their functionality and efficacy. One standout feature is the electric motor, which not only increases sewing speed but also ensures greater consistency in stitches. This is particularly important in leatherwork, where precision is crucial to maintaining the aesthetic appeal and durability of the final product.

Additionally, many Chinese motorized sewing machines come with built-in computer systems that allow for intricate pattern designs and automatic adjustments based on the type and thickness of leather being used. This technological advancement significantly reduces the need for skilled labor, lowering production costs and increasing overall efficiency.

Moreover, the durability and robustness of these machines have gained recognition. Made with high-quality materials, they are designed to withstand the rigors of heavy-duty sewing, making them an ideal choice for factories and workshops focusing on leather production.

motorized chinese leather sewing machine

Economic Impact

The widespread adoption of motorized Chinese leather sewing machines has had profound effects on the global leather market. For manufacturers, these machines have enabled them to meet rising consumer demand without sacrificing quality. By increasing production capacity, businesses can take on larger orders and react more swiftly to market trends.

For individual artisans and small-batch producers, these machines present an opportunity to elevate their craftsmanship. Traditional methods can be combined with modern technology, allowing for unique and bespoke leather goods that satisfy the growing consumer preference for handcrafted items. As a result, the motorized sewing machine serves as a bridge between artisanal quality and industrial efficiency.

Furthermore, the affordability of these machines compared to their Western counterparts has made them accessible to a wider range of producers. Start-ups and small businesses can invest in these machines without breaking the bank, fostering creativity and innovation in the leather goods market.

Challenges and Future Prospects

Despite their many advantages, motorized Chinese leather sewing machines are not without challenges. Issues such as quality control, machine maintenance, and technical support can pose problems for manufacturers who are unfamiliar with technological nuances. Additionally, competition is fierce, with numerous brands vying for market share both domestically and internationally.

Looking ahead, the future of motorized leather sewing machines in China appears promising. As technology continues to evolve, we can anticipate further advancements in automation, artificial intelligence, and user-friendly design features. Manufacturers will likely enhance their sustainability efforts as well, developing machines that are more energy-efficient and capable of using eco-friendly materials.

In conclusion, motorized Chinese leather sewing machines represent a significant leap forward in the production of leather goods. They embody the fusion of tradition and innovation, empowering manufacturers and artisans alike to redefine what is possible in leather crafting. As technology continues to advance, the leather industry will undoubtedly see even greater transformations, setting the stage for new trends and opportunities in the years to come.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025