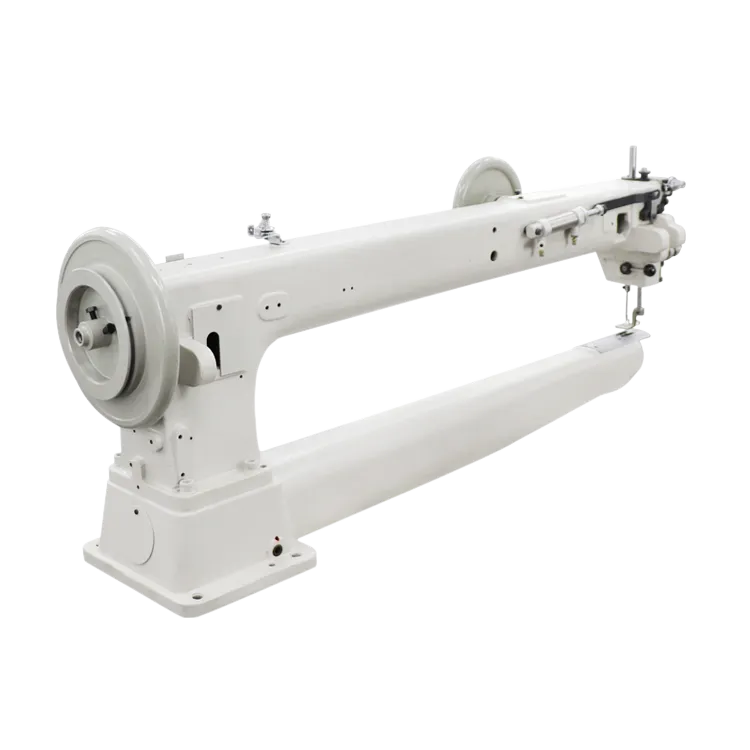

long reach and elevated arm sail fabrication equipment

Understanding the Long Arm and High Arm Sail Making Machine

The art of sail making has long been an integral part of maritime culture, enabling vessels to harness wind power for navigation and travel. As the industry evolved, so too did the tools and machines used in the crafting of sails. Among the most significant innovations in recent years is the long arm and high arm sail making machine. This advanced piece of equipment represents a leap in efficiency, accuracy, and versatility in the sail manufacturing process.

At its core, the long arm and high arm sail making machine is designed to handle large pieces of fabric required for sail production. Traditional sail making often involved manually cutting, sewing, and assembling sails, which was not only labor-intensive but also prone to human error. The introduction of this specialized machine mitigates many of the challenges associated with manual production. By utilizing a long arm design, this machine can accommodate larger fabric sections without the need for constant repositioning of the material.

Moreover, the high arm feature enhances the machine’s ability to work with thicker fabrics and multiple layers, which is essential for creating durable and reliable sails. This capability allows manufacturers to produce high-quality sails that can withstand the rigors of the open sea while maintaining optimal performance. The high arm also provides the necessary clearance for stitching heavy seams that are commonplace in sail construction, thereby making the process more efficient.

'long arm and high arm sail making machine'

One of the standout features of the long arm and high arm sail making machine is its automation capability. Modern machines are often equipped with computerized systems that allow for precision cutting and stitching. This significantly reduces the risk of errors that may arise during manual sewing, ensuring that each sail is made to exact specifications. Advanced software can also assist in design alterations, enabling manufacturers to quickly adapt to different sail designs whether for racing yachts, cruising boats, or even large commercial vessels.

Furthermore, this machine stands out in terms of versatility. The adaptability of the long arm and high arm sail making machine extends beyond just sail production. It can be employed in other fabric-related industries, such as tent making, awning production, and even in some automotive applications. This multi-functionality makes it a valuable investment for manufacturers looking to optimize their workspace and increase productivity.

The sustainability of manufacturing also benefits from advancements in machinery like the long arm and high arm sail making machine. With more precise cutting and sewing, there is less fabric waste, effectively making the production process more environmentally friendly. Given the growing focus on sustainability within the maritime industry, these machines help manufacturers adopt greener practices while still meeting market demands.

In conclusion, the long arm and high arm sail making machine represents a significant advancement in the field of sail production. By increasing efficiency, ensuring precision, and enhancing versatility, it serves as an essential tool for sail makers who seek to uphold the highest standards in craftsmanship while navigating the demands of modern time. As technology continues to evolve, it is likely that we will see further innovations in the sail making process, paving the way for improved performance and sustainability in the maritime industry. Whether for sport, leisure, or commercial use, the sails produced with this modern machinery undoubtedly contribute to the ongoing legacy of sailing and the skilled craft of sail making.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025