leather bag making machine

The Evolution of Leather Bag Making Machines

In the world of fashion, leather bags have long been synonymous with luxury, durability, and style. From high-end designer pieces to everyday carryalls, leather bags hold a revered place in both utility and fashion. As the demand for leather goods continues to rise, the industry has witnessed significant advancements in production techniques — particularly in the realm of leather bag making machines. These machines have revolutionized the way leather goods are crafted, streamlining processes that were once labor-intensive and time-consuming.

The Role of Leather Bag Making Machines

Leather bag making machines serve multiple purposes in the production process. They are equipped to cut, stitch, and assemble various components of the bag with precision and efficiency. Traditional methods of leather crafting often relied heavily on skilled artisans, which, while ensuring high quality, limited the scalability of production. With the advent of specialized machinery, manufacturers can now produce high-quality leather bags in larger quantities without compromising on detail and craftsmanship.

Types of Leather Bag Making Machines

1. Cutting Machines These machines accurately cut leather pieces according to intricate patterns. Laser cutting technology is becoming increasingly popular in this sector due to its accuracy and speed. This precision minimizes waste and enhances the overall sustainability of the production process.

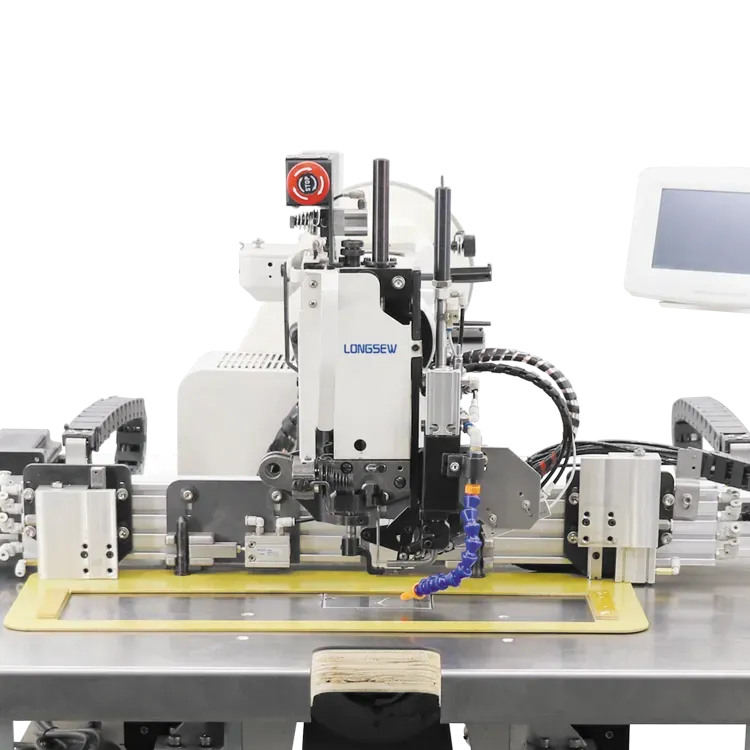

2. Stitching Machines Stitching machines are crucial for assembling the components of a leather bag. Unlike traditional hand-stitching, which can be painstakingly slow, modern stitching machines offer various stitching options, including straight, zigzag, and decorative stitches, allowing manufacturers to achieve intricate designs quickly and efficiently.

3. Die Cutting Machines Used for shaping specific components, die cutting machines can create various designs quickly. The use of dies ensures that each piece is uniform, which is essential for the overall aesthetic and functionality of the bag.

4. Edge Finishing Machines The edges of leather bags must be finished meticulously to enhance durability and appearance. Edge finishing machines offer consistent results that would be challenging to achieve through manual labor, providing a polished look that is crucial for high-end products.

5. Embossing and Printing Machines These machines allow for customization and branding of leather products. Whether it’s a logo or unique design, embossing and printing technology can add distinctiveness to any leather bag.

leather bag making machine

Benefits of Automation in Leather Bag Production

The integration of technology in leather bag manufacturing presents numerous benefits. Firstly, it significantly reduces production time, enabling brands to meet growing consumer demands efficiently. This speed also allows for quicker adaptation to market trends and seasonal changes in fashion.

Secondly, automating the production process enhances quality control. Machines can consistently replicate the same output, resulting in uniformity that is difficult to achieve through handcrafting alone. This consistency in quality is paramount, especially for luxury brands that pride themselves on their craftsmanship.

Finally, the use of these machines can lead to cost savings. While the initial investment in machinery may be substantial, the long-term benefits, such as lower labor costs and increased output, often outweigh the expenses. Moreover, with improved efficiency and reduced waste, manufacturers can enhance their profit margins.

Challenges and Considerations

Despite the compelling advantages, the transition to mechanized production does pose challenges. The need for skilled machine operators can create a skills gap in the workforce, as traditional artisans may not have the necessary technical training. Additionally, reliance on machines can reduce the amount of human touch that some consumers cherish in handcrafted goods.

Brands must balance automation with craftsmanship to maintain their identity and appeal to consumers who appreciate artisanal quality. Finding that equilibrium will be crucial in shaping the future of leather bag production.

Conclusion

The leather bag making machine has transformed the industry by combining traditional craftsmanship with modern technology. As manufacturers continue to innovate and adapt these machines, the leather goods market is poised for growth. By enhancing efficiency, quality, and sustainability, these machines ensure that the tradition of leather crafting endures, even as it evolves to meet contemporary demands. The future of leather bags is bright, blending timeless elegance with innovative production methods, creating products that are not only beautiful but also reflect the values of modern consumers.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025