Innovative Solutions for Efficient Bulk Bag Production and Manufacturing Equipment Options

The Evolution and Importance of Bulk Bag Making Machines

In today’s fast-paced manufacturing industry, efficiency and precision are pivotal to maintaining a competitive edge. Among various technological advancements, bulk bag making machines stand out as essential equipment for companies involved in packaging large quantities of materials. These machines are specifically designed to produce flexible intermediate bulk containers (FIBCs), commonly referred to as bulk bags. This article delves into the fundamental aspects of bulk bag making machines, their functionality, and their significance in modern manufacturing.

Understanding Bulk Bags

Bulk bags are flexible containers capable of holding substantial weights, typically ranging from 500kg to 2000kg or more. They are extensively used in various industries including agriculture, chemicals, pharmaceuticals, and construction. Their primary purpose is to facilitate the transportation and storage of dry bulk materials, granulated substances, and powders. The design of bulk bags allows for easy handling, loading, and unloading, making them a preferable choice over traditional packaging methods such as drums or boxes.

Functionality of Bulk Bag Making Machines

Bulk bag making machines automate the production of these versatile bags, significantly enhancing manufacturing efficiency. The machines operate through a series of meticulous steps

1. Material Feeding The process begins with feeding raw materials, typically woven polypropylene or polyethylene, into the machine. These materials are chosen for their durability and resistance to moisture and chemical exposure.

2. Fabric Cutting and Seaming The machine skillfully cuts the fabric into precise dimensions before welding or sewing the seams together. This step ensures that the bags are robust and capable of withstanding heavy loads.

3. Forming and Filling Once the basic bag structure is formed, additional features such as spouts or duffle tops may be added. These features allow for convenient filling and discharge of contents.

4. Quality Control An integrated quality inspection system ensures that each bag meets industry standards for strength and safety before it is packaged for shipment.

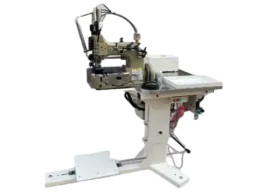

bulk bag making machine

Advantages of Bulk Bag Making Machines

1. Increased Productivity These machines can produce a high volume of bulk bags in significantly less time than manual production methods. This advantage reduces lead times and helps meet customer demand promptly.

2. Cost-Effectiveness By automating the manufacturing process, companies can significantly reduce labor costs and minimize material waste, leading to better profit margins.

3. Consistency and Quality Bulk bag making machines ensure uniformity in production, leading to consistent bag quality. This is crucial for industries where product integrity is vital.

4. Customization Many modern machines offer customization options for bag sizes, designs, and printing. Businesses can create branded bulk bags that enhance their marketing while serving logistical needs.

The Future of Bulk Bag Manufacturing

As demand for bulk bags continues to grow, the technology behind bulk bag making machines is also evolving. Innovations such as smart manufacturing, artificial intelligence, and IoT integration are anticipated to streamline processes further, improving efficiency and reducing operational costs. Additionally, as sustainability becomes a significant concern, there is a growing trend towards using recyclable materials in bulk bag production, which aligns with global environmental goals.

Conclusion

In conclusion, bulk bag making machines play a crucial role in modern manufacturing, enabling industries to package and transport materials efficiently and safely. Their ability to enhance productivity, reduce costs, and maintain consistent quality has made them indispensable in various sectors. As technology continues to advance, the future of bulk bag production promises even greater innovations that will further elevate its significance in the global market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025