Innovative Automatic Sewing Machines Designed for Efficient Factory Production and Enhanced Workflows

The Rise of Automatic Sewing Machines in Factories

In the rapidly evolving landscape of the textile and garment industry, automatic sewing machines are becoming an indispensable asset for factories worldwide. These advanced machines represent a significant leap in technology, improving efficiency, productivity, and quality while addressing the growing demands of the market.

Enhanced Efficiency

One of the most significant advantages of automatic sewing machines is their ability to enhance efficiency. These machines are built to operate at high speeds, performing tasks that would take human workers considerably longer. With advanced features such as automated thread cutting, fabric feeding, and stitching patterns, they minimize downtime and reduce the need for manual intervention. This not only accelerates the production process but also ensures a more consistent output, allowing factories to meet tight deadlines and increasing their competitiveness.

Improved Quality Control

Quality is paramount in the textile industry, and automatic sewing machines contribute significantly to maintaining high standards. Equipped with precision-engineered components and sophisticated software, these machines produce uniform stitches and consistent seam quality that are often challenging to achieve through manual sewing. Many models are also designed to automatically adjust tension and stitch length based on fabric type, further ensuring the integrity of the finished product. With fewer human errors, factories can significantly reduce waste and rework, leading to improved quality control and lower production costs.

Labor Considerations

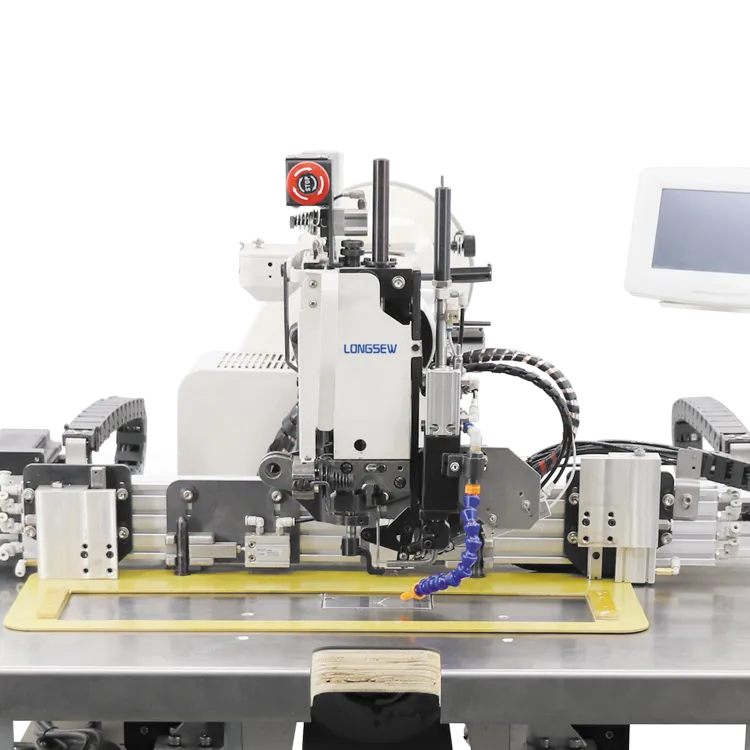

automatic sewing machine for factory

While the introduction of automatic sewing machines raises concerns about job displacement, it also creates new opportunities within the industry. As factories adopt these technologies, the demand for skilled technicians and operators who can maintain and program the machines increases. Moreover, labor-intensive tasks can be reassigned to more complex and creative activities that require human oversight, allowing workers to focus on higher-value assignments. This shift can lead to a more skilled workforce, capable of adapting to the evolving technological landscape.

Sustainability and Cost-Effectiveness

The shift towards automatic sewing machines aligns with the growing focus on sustainability in the manufacturing sector. These machines are designed to optimize material usage, reducing fabric waste through precise cutting and sewing techniques. Additionally, the efficiency gains translate into lower energy consumption per unit produced, making automatic sewing machines a more sustainable choice. In the long run, the initial investment in these technologies can lead to significant cost savings, making them an attractive option for factory owners seeking to enhance their bottom line.

Adaptability and Technological Integration

Modern automatic sewing machines are not just faster and more efficient; they are also increasingly adaptable. With the integration of Industry 4.0 principles, these machines can communicate with other systems within the factory, such as inventory management and production scheduling software. This interconnectedness allows for real-time monitoring and data analysis, enabling factory managers to make informed decisions that optimize production flow and resource allocation.

Conclusion

As the textile and garment industry continues to face the challenges of globalization and consumer demand for faster, high-quality products, automatic sewing machines will play a vital role in shaping the future of factory operations. By enhancing efficiency, improving quality control, and promoting sustainability, these machines stand at the forefront of technological innovation in manufacturing. As factories embrace this new wave of automation, they not only enhance their productivity but also contribute to a smarter, more sustainable industrial ecosystem. The future of sewing in factories is not just about speed; it's about harnessing technology to elevate every aspect of production while meeting the dynamic needs of the market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025