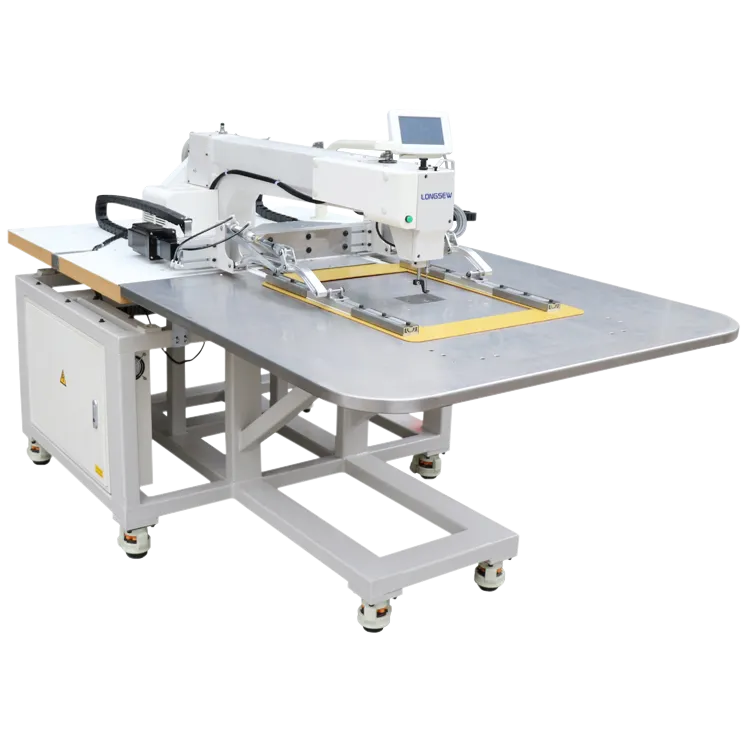

industrial flatbed sewing machine

The Importance of Industrial Flatbed Sewing Machines in Modern Manufacturing

In the realm of textile manufacturing, efficiency, precision, and speed are paramount. Among the various tools that manufacturers rely on, industrial flatbed sewing machines hold a prominent position. These machines are indispensable in producing a wide range of products, from clothing and upholstery to industrial textiles and accessories. Understanding their importance can shed light on why they are the backbone of the sewing industry.

An industrial flatbed sewing machine is designed for heavy-duty, high-volume sewing tasks. Unlike domestic sewing machines, which are typically built for occasional use, industrial flatbed machines are engineered to withstand the demands of continuous operation. They feature robust construction and powerful motors, allowing them to handle thicker materials and multiple layers with ease. This durability makes them ideal for factories that require consistent performance over long periods, reducing downtime and increasing productivity.

One of the key advantages of flatbed sewing machines is their versatility. They can be equipped with various attachments and feet, enabling them to perform a multitude of stitches and techniques. Whether it’s straight stitching, zig-zag stitching, or even specialty stitches like decorative or buttonhole stitching, flatbed machines can adapt to diverse sewing requirements. This flexibility allows manufacturers to produce a wide variety of products without needing to change machines frequently, streamlining the production process.

industrial flatbed sewing machine

Moreover, the design of these machines facilitates ease of use and precision. The flatbed surface offers ample workspace for fabric manipulation, which is crucial for achieving accuracy in stitching. Operators can easily guide the material through the machine, maintaining straight lines and consistent patterns. This level of control is particularly important for industries that prioritize high-quality finishes, such as fashion and upholstery.

In addition to their operational advantages, industrial flatbed sewing machines contribute to cost efficiency in manufacturing. With the ability to sew faster than domestic machines, they significantly reduce the time needed for production cycles. Faster production rates mean that manufacturers can meet market demands promptly, reducing lead times and increasing customer satisfaction. Furthermore, the durability and reliability of these machines minimize repair costs and ensure longevity, making them a smart investment for businesses.

The rise of e-commerce and fast fashion has intensified the competition in the sewing industry. As companies strive to optimize their production processes and reduce costs, investing in high-quality industrial flatbed sewing machines has become essential. They not only boost productivity but also enhance the quality of the final products, setting manufacturers apart in a crowded market.

In conclusion, industrial flatbed sewing machines play a vital role in modern textile manufacturing. Their strength, versatility, and efficiency equip manufacturers to navigate the challenges of today's fast-paced market. As the industry continues to evolve, these machines will remain crucial in driving growth and innovation in the textile sector.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025