Mrz . 04, 2025 02:50

Back to list

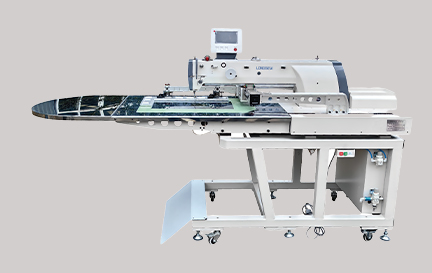

chain stitch sewing machine

The harness sewing machine, a specialized piece of equipment, has long been lauded in industries that require durable and robust stitching, especially in harness and heavy-duty fabric creation. Those who have had the opportunity to work with a harness sewing machine understand the distinct advantages it offers. With precise engineering and exceptional build quality, these machines are capable of stitching thick materials such as leather, canvas, and heavy synthetic fabrics with ease and efficiency. This expertise-driven exploration will delve into the essential experience, features, and benefits of harness sewing machines.

The authority of a harness sewing machine within its niche stems from its capacity to meet stringent quality standards. Within industries where fabric strength and integrity are crucial, such as automotive upholstering or outdoor gear manufacturing, these machines set the benchmark. Brands specializing in these machines often provide extensive warranties, technical support, and training materials, emphasizing their commitment to customer satisfaction and the dependable performance of their products. Trustworthiness, a critical component of any high-value purchase, is inherently tied to the harness sewing machine's track record. Manufacturers and suppliers who focus on these machines are typically long-established entities with significant expertise and positive reputations built over years of serving specialized industries. Consumers seeking to invest in these sewing machines often prioritize companies known for their rigorous quality control and dedication to technological innovation - factors that instill confidence in their purchasing decision. In conclusion, the harness sewing machine represents a pinnacle of sewing technology, crafted specifically to handle the rigors of manufacturing durable, high-quality products. For those in industries where strength and reliability are non-negotiable, investing in a harness sewing machine is not merely a matter of upgrading equipment; it is an enhancement of craft and capability. The experience gained, fueled by the machine's expertise-driven design, is unparalleled, offering a level of authority in craftsmanship that few other tools can match. Trust in these machines is not misplaced, as they have consistently demonstrated their worth in the most demanding of environments.

The authority of a harness sewing machine within its niche stems from its capacity to meet stringent quality standards. Within industries where fabric strength and integrity are crucial, such as automotive upholstering or outdoor gear manufacturing, these machines set the benchmark. Brands specializing in these machines often provide extensive warranties, technical support, and training materials, emphasizing their commitment to customer satisfaction and the dependable performance of their products. Trustworthiness, a critical component of any high-value purchase, is inherently tied to the harness sewing machine's track record. Manufacturers and suppliers who focus on these machines are typically long-established entities with significant expertise and positive reputations built over years of serving specialized industries. Consumers seeking to invest in these sewing machines often prioritize companies known for their rigorous quality control and dedication to technological innovation - factors that instill confidence in their purchasing decision. In conclusion, the harness sewing machine represents a pinnacle of sewing technology, crafted specifically to handle the rigors of manufacturing durable, high-quality products. For those in industries where strength and reliability are non-negotiable, investing in a harness sewing machine is not merely a matter of upgrading equipment; it is an enhancement of craft and capability. The experience gained, fueled by the machine's expertise-driven design, is unparalleled, offering a level of authority in craftsmanship that few other tools can match. Trust in these machines is not misplaced, as they have consistently demonstrated their worth in the most demanding of environments.

Next:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025