Optimizing FIBC Belt Sewing Techniques for Enhanced Durability and Performance in Cargo Handling

The Importance of FIBC Belt Sew Ensuring Quality and Safety in Bulk Transport

Flexible Intermediate Bulk Containers (FIBCs), also known as bulk bags, are an essential component in various industries for transporting and storing granular materials, powders, and other bulk goods. A crucial aspect of ensuring the durability and reliability of these containers lies in the sewing techniques used, particularly the FIBC belt sew. This article will delve into the significance of FIBC belt sew, the methods employed, and its impact on the overall performance of bulk bags.

Understanding FIBC Bags

FIBC bags are constructed from woven polypropylene fabric and are designed to hold large quantities of materials. They come in various shapes and sizes, often tailored to meet specific requirements for different applications. The construction of these bags must be robust to withstand the stresses associated with transporting heavy loads. Proper sewing techniques, particularly at the seams and belt areas, are essential for maintaining structural integrity and safety during handling.

The Role of Belt Sew in FIBC Bags

The term belt sew refers to the sewing technique used to attach the belts or lifting loops to the FIBC. These lifting loops are crucial for maneuvering the bags with forklifts or cranes. The quality of the belt sew directly affects the bag's load-bearing capacity and safety during transportation. If the seams are not properly sewn, the lifting loops may fail, leading to accidents and potential loss of materials.

Techniques for Quality FIBC Belt Sew

1. Double Stitching One of the most common techniques used for FIBC belt sew is double stitching. This method involves sewing two parallel lines of stitches along the seam, providing additional strength and reducing the risk of seam failure. Double stitching is particularly important for heavy-duty FIBCs that carry significant loads.

fibc belt sew

2. Use of High-Strength Thread The choice of thread plays a pivotal role in the durability of the belt sew. High-strength polyester or nylon threads are often used due to their resistance to abrasion and UV degradation. These threads are designed to endure the stresses of lifting and transporting bulk materials, thereby enhancing the overall lifespan of the FIBC.

3. Reinforcement Panels For added durability, manufacturers often incorporate reinforcement panels at the attachment points of the lifting loops. These panels distribute the load more evenly, reducing the strain on the seams and minimizing the risk of failure.

4. Quality Control Rigorous quality control measures are crucial in ensuring that the FIBC belt sew meets industry standards. Regular inspections and testing are performed during the manufacturing process to verify the strength and reliability of the seams. Adhering to international standards, such as ISO 21898, can significantly enhance safety and performance.

The Impact of Poor Belt Sew

The consequences of inadequate FIBC belt sew can be severe. A failure in the lifting loops can result in the bag dropping unexpectedly, causing damage to the contents, injury to personnel, and potential environmental hazards. Additionally, poor sewing can lead to leaks or spills, further complicating logistics and increasing costs. Therefore, investing in high-quality sewing techniques is essential for ensuring the safe handling of bulk materials.

Conclusion

In the realm of bulk transport, FIBC bags are invaluable, and their effectiveness largely hinges on the quality of construction, particularly in the area of belt sew. By utilizing advanced sewing techniques, high-strength materials, and stringent quality control, manufacturers can produce FIBC bags that ensure safety, reliability, and efficiency in transporting bulk goods. As industries continue to rely on FIBC bags for their operations, understanding and prioritizing the importance of belt sew will be crucial for optimizing performance and safeguarding both personnel and materials.

In summary, investing in robust sewing techniques is not just a manufacturing concern; it is an essential practice that directly impacts the success of bulk handling operations. As the demand for efficient logistics solutions grows, so does the need for high-quality FIBC bags, making belt sew a pivotal aspect of modern supply chain management.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

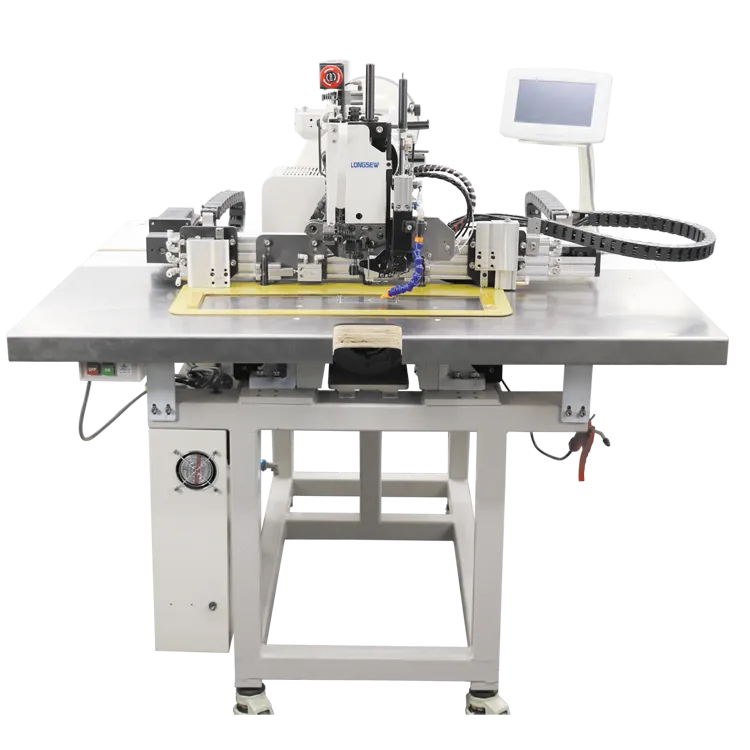

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025