Essential Guide to Upholstery Machine Needles for Optimal Sewing Performance

Understanding Upholstery Machine Needles

Upholstery is an art form that combines creativity and technical skill to produce beautiful, functional pieces for furniture and home décor. One of the essential tools in the upholstery process is the upholstery machine needle, a seemingly simple but crucial component that significantly impacts the quality and durability of the finished product.

Understanding Upholstery Machine Needles

There are a few key features to consider when selecting the right upholstery machine needle. The needle size is crucial; thicker materials require larger, heavier needles. Typically, upholstery needles range from size 80/12 for lightweight fabrics to size 110/18 for heavy-duty materials like leather, canvas, and multiple layers of fabric. Choosing the correct needle size helps to prevent damage to both the fabric and the needle itself, ensuring smooth and efficient stitching.

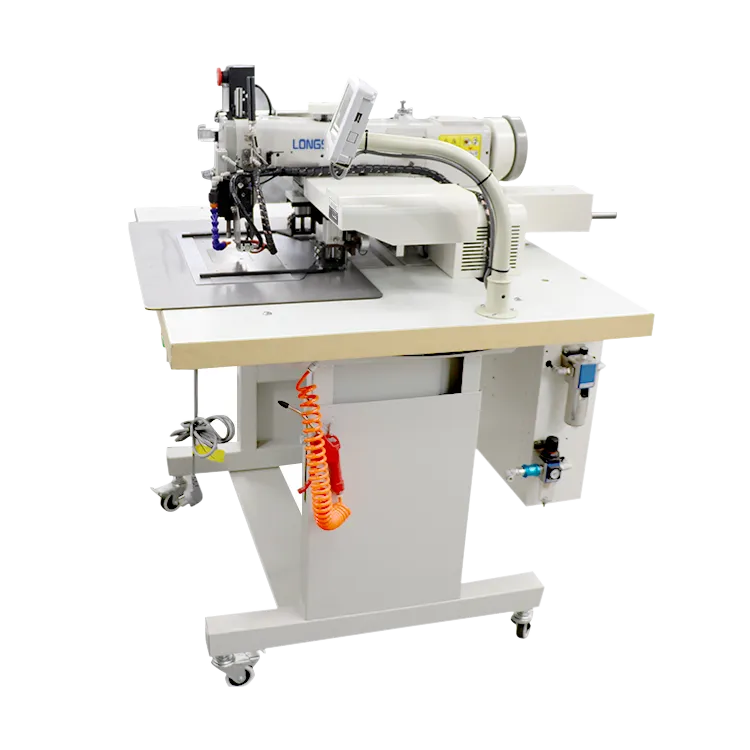

upholstery machine needles

Additionally, the type of needle point is essential. There are several styles, including the universal point, which is versatile for various applications, and the wedge point, specially designed for thick materials like leather or upholstery fabrics. The wedge point slices through layers without creating snags, making it ideal for upholstery projects.

Using the wrong needle can lead to several issues, such as skipped stitches, fabric damage, or even needle breakage, which can interrupt the workflow and lead to costly repairs. Therefore, understanding the different types of upholstery machine needles and their uses will enable upholsterers to achieve professional results.

Moreover, as technology in the sewing machine industry evolves, so do the needles. Modern upholstery needles may feature innovations such as anti-friction coatings or specialized eye designs that reduce thread breakage and improve sewing efficiency. These advancements allow for faster, smoother stitching, which is vital in a production setting.

In conclusion, selecting the correct upholstery machine needle is an integral part of successful upholstery work. By understanding the various needle types, sizes, and advancements in needle technology, upholsterers can enhance their skills, improve the quality of their finished products, and ultimately bring their creative visions to life. Whether you are a professional or a DIY enthusiast, investing time in choosing the right needle pays off in increased efficiency and superior craftsmanship.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025