Innovative Design for Efficient Cylinder Sewing Machines in Modern Textile Production

The Revolutionary Impact of Cylindrical Sewing Machines

In the ever-evolving world of textile and garment manufacturing, the cylindrical sewing machine has carved out a significant niche. Known for its unique design and functionality, this machine has transformed the way industries approach sewing processes, enhancing efficiency and output quality.

Cylindrical sewing machines are engineered to handle tubular fabrics and garments, which are commonly found in the apparel industry. Unlike conventional flat sewing machines, the cylindrical variant is designed to accommodate the rounded shapes of items such as sleeves, cuffs, and other tubular components. This makes it indispensable in the production of items like shirts, blouses, and trousers. The machine’s ability to sew circular seams with precision allows manufacturers to achieve clean finishes and minimized fabric waste, leading to both cost effectiveness and enhanced product quality.

One of the key advantages of cylindrical sewing machines is their versatility. While they excel in producing tubular sections, many advanced models come equipped with interchangeable attachments and features that allow for a variety of stitching patterns and techniques. This adaptability means that manufacturers can produce a wide range of garments without needing to invest in multiple types of sewing machines. In a competitive marketplace, the ability to rapidly shift production to accommodate different designs can provide a strategic edge.

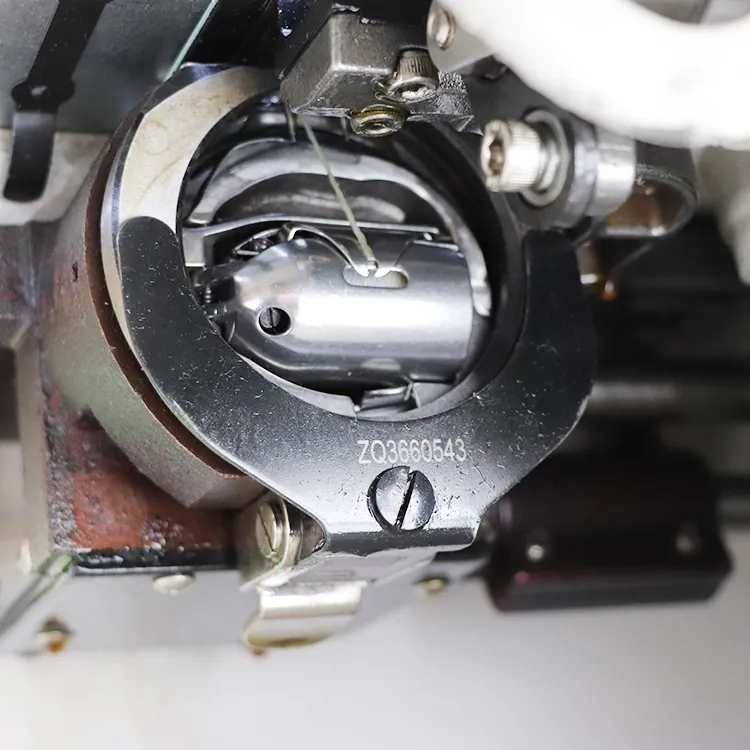

cylindrical sewing machine

Moreover, the implementation of cylindrical sewing machines has improved production speed. With innovations in technology, automated features such as thread trimming and automatic tension adjustments have been integrated into these machines. Such advancements reduce the amount of manual adjustments needed, thereby accelerating the sewing process and allowing companies to meet tight deadlines and large order quantities more efficiently.

The ergonomic design of cylindrical sewing machines also contributes to operator comfort and productivity. The configuration allows for better visibility of the sewing area, reducing strain on operators and minimizing errors. Enhanced operator comfort not only boosts morale but can also lead to lower turnover rates, benefitting companies by retaining skilled labor.

In our fast-paced fashion industry, where trends can change overnight, the efficiency, adaptability, and precision of cylindrical sewing machines secure their place as a vital asset. As manufacturers continue to innovate and streamline processes, it is clear that these machines will remain at the forefront of sewing technology, shaping the future of garment production. Ultimately, their impact goes beyond just efficiency; they enable creativity and quality in a market that constantly demands more from its players.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025