Innovative Cylinder Sewing Machine for Efficient Fabric Processing and Seamless Production

The Evolution and Significance of the Cylinder Sewing Machine

The cylinder sewing machine is a specialized type of sewing equipment designed to meet the unique needs of the garment industry, particularly in the production of items requiring a cylindrical shape. This innovative machine has substantially influenced the fashion and textile sectors, enabling manufacturers to enhance productivity, accuracy, and overall quality in their garment production processes.

Historical Background

The origins of the cylinder sewing machine can be traced back to the 19th century, a period marked by significant advancements in textile manufacturing. Before the advent of this specialized machine, sewing was predominantly done by hand or with flat-bed sewing machines, which were ill-equipped to efficiently sew tubular garments like sleeves, cuffs, and the bodies of certain apparel. As clothing styles evolved, the demand for more efficient sewing solutions grew, leading to the development of the cylinder sewing machine.

Design and Functionality

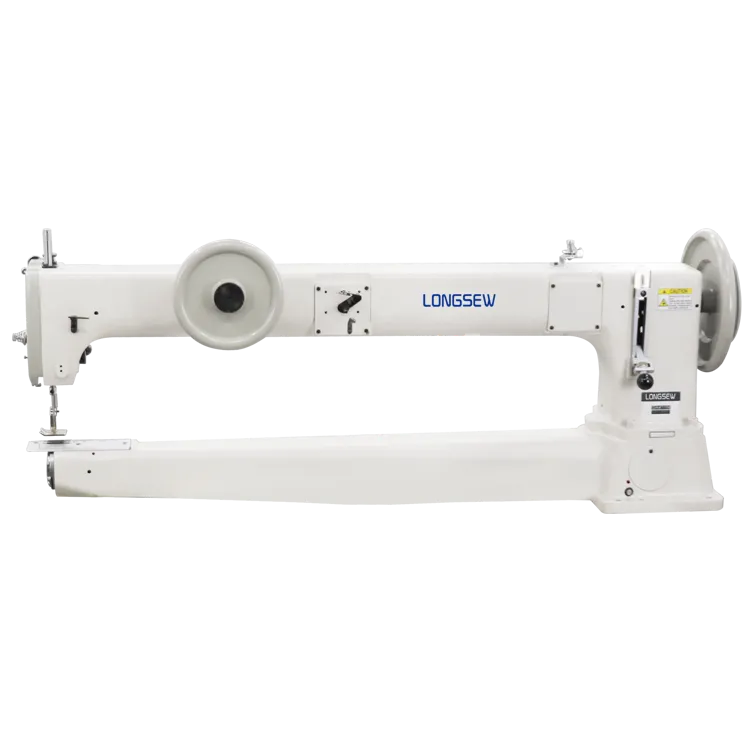

The cylinder sewing machine features a unique cylindrical arm that provides a seamless workspace for sewing tubular items. This distinctive design allows for easy maneuverability of fabric around the needle, which is crucial for achieving precise stitches in garments such as t-shirts, pants, and other fitted apparel. Unlike traditional flat-bed machines, the cylinder design eliminates the struggle associated with handling rolled or curved materials, thus improving both the speed and accuracy of the sewing process.

Advantages of Cylinder Sewing Machines

cylinder sewing machine

One of the significant advantages of the cylinder sewing machine is its ability to handle a variety of fabrics, from lightweight materials like silk to heavier fabrics like denim. The machine's specialized presser feet and adjustable tension settings make it adaptable to different sewing requirements, allowing for the creation of intricate patterns and high-quality finishes. Additionally, cylinder sewing machines can often accommodate multiple threading options, enhancing versatility in stitching techniques and styles.

Another crucial benefit is the time efficiency it offers. Assembly line production is streamlined due to the machine’s ability to sew complicated seams in a shorter time frame. This efficiency not only meets the increasing demand for quick turnaround times in the fashion industry but also helps businesses reduce labor costs and increase overall productivity.

Technological Advancements

The continuous evolution of technology has further enhanced the functionality of cylinder sewing machines. Modern versions are often equipped with computerized controls, enhancing precision and offering various stitch patterns that can be customized according to the manufacturer’s needs. This technological integration has allowed for the rapid adaptation to changing fashion trends and consumer tastes without sacrificing quality.

Conclusion

In conclusion, the cylinder sewing machine represents a significant development in the world of garment manufacturing. Its design specifically addresses the complexities associated with sewing cylindrical shapes, making it an indispensable tool in modern apparel production. As technological advancements continue to emerge, the capabilities of cylinder sewing machines are only expected to grow, enabling the fashion industry to keep pace with evolving consumer demands and preferences. Thus, the cylinder sewing machine remains a vital asset, contributing to the efficiency, creativity, and sustainability of clothing manufacturing in today’s fast-paced world.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025