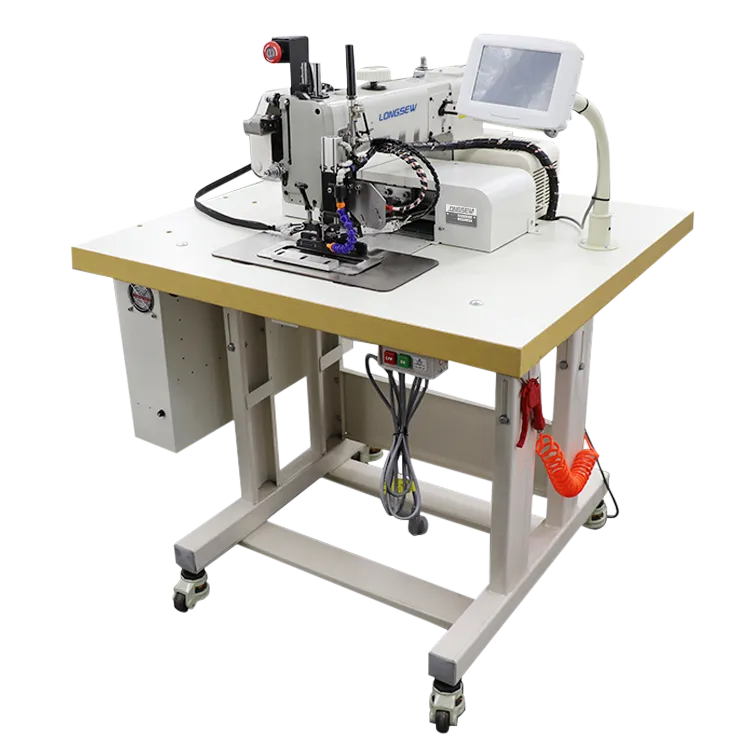

Advanced CNC Pattern Sewing Machines for Precision Fabric Crafting and Design

The Rise of CNC Pattern Sewing Machines in the Textile Industry

In the ever-evolving world of textile manufacturing, the integration of technology has sparked a revolution, leading to unprecedented efficiency and precision in production processes. One of the most significant advancements in this field is the introduction of CNC (Computer Numerical Control) pattern sewing machines. These machines represent a remarkable shift from traditional sewing methods, facilitating the seamless creation of intricate patterns and designs with minimal human intervention.

What is a CNC Pattern Sewing Machine?

A CNC pattern sewing machine is an innovative tool that employs computer software to control the sewing process. Unlike conventional sewing machines, which require manual input for every stitch and pattern, CNC machines are programmed with precise specifications. This programmability allows them to work with great accuracy, producing intricate designs that would be labor-intensive and time-consuming if done manually.

The core technology relies on a computer interface, where designers input specific patterns and parameters. The machine then executes the design autonomously, ensuring consistency across multiple fabric pieces. This capability is particularly beneficial in industries requiring mass production of textiles, where uniformity is crucial.

Advantages of CNC Pattern Sewing Machines

1. Increased Precision CNC pattern sewing machines are renowned for their exceptional precision. The technology eliminates human error associated with manual sewing. This precision translates into higher quality products, reducing the likelihood of defects and enhancing customer satisfaction.

2. Efficiency and Speed The speed at which CNC machines operate is significantly higher than manual sewing techniques. They can quickly produce complex patterns, which can drastically reduce production time. This efficiency not only optimizes resource use but also allows businesses to fulfill larger orders in shorter timeframes.

3. Design Flexibility With computerized programming, designers have the freedom to create intricate and unique patterns without the constraints of manual sewing. This flexibility encourages innovation and allows brands to respond rapidly to market trends and customer preferences.

cnc pattern sewing machine

4. Cost-Effectiveness While the initial investment in CNC technology might be high, the long-term savings are substantial. The reduction in labor costs, combined with lower material waste and enhanced production rates, makes CNC pattern sewing machines a wise investment for textile manufacturers.

5. Reduced Workforce Requirements The automation provided by CNC machines reduces the need for a large workforce. This transition may raise concerns regarding job displacement; however, it creates opportunities for upskilling workers to manage and maintain these advanced machines, enhancing their value in the workforce.

Impact on the Textile Industry

The introduction of CNC pattern sewing machines has had a transformative impact on the textile industry. Companies adopting this technology have reported not only enhanced production capabilities but also a significant increase in creative potential. Designers can experiment with new patterns and collections more freely and with reduced risk, fostering a culture of innovation.

Moreover, the sustainability of textile manufacturing is benefited by CNC technology. The precision of machine stitching allows for less fabric waste during the cutting and sewing processes, aligning with the industry's growing focus on eco-friendly practices.

Challenges and Future Prospects

Despite the myriad advantages, the adoption of CNC pattern sewing machines is not without challenges. The initial investment and ongoing maintenance costs can be steep, particularly for small to medium-sized enterprises. Additionally, the need for skilled technicians to operate and program these machines is critical, necessitating substantial training and education resources.

Looking towards the future, the continued advancement of CNC technology is expected to further integrate artificial intelligence and machine learning. This evolution could lead to even more sophisticated sewing machines that can learn from previous designs and adjust their programming in real-time, setting a new standard for the textile industry.

In conclusion, CNC pattern sewing machines are at the forefront of a significant transformation in the textile manufacturing landscape. Their ability to enhance precision, efficiency, and creativity positions them as invaluable tools in the industry. As technology continues to evolve, the potential for CNC machines to reshape textile production is limitless, paving the way for a more innovative and sustainable future.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025