Jan . 09, 2025 12:40

Back to list

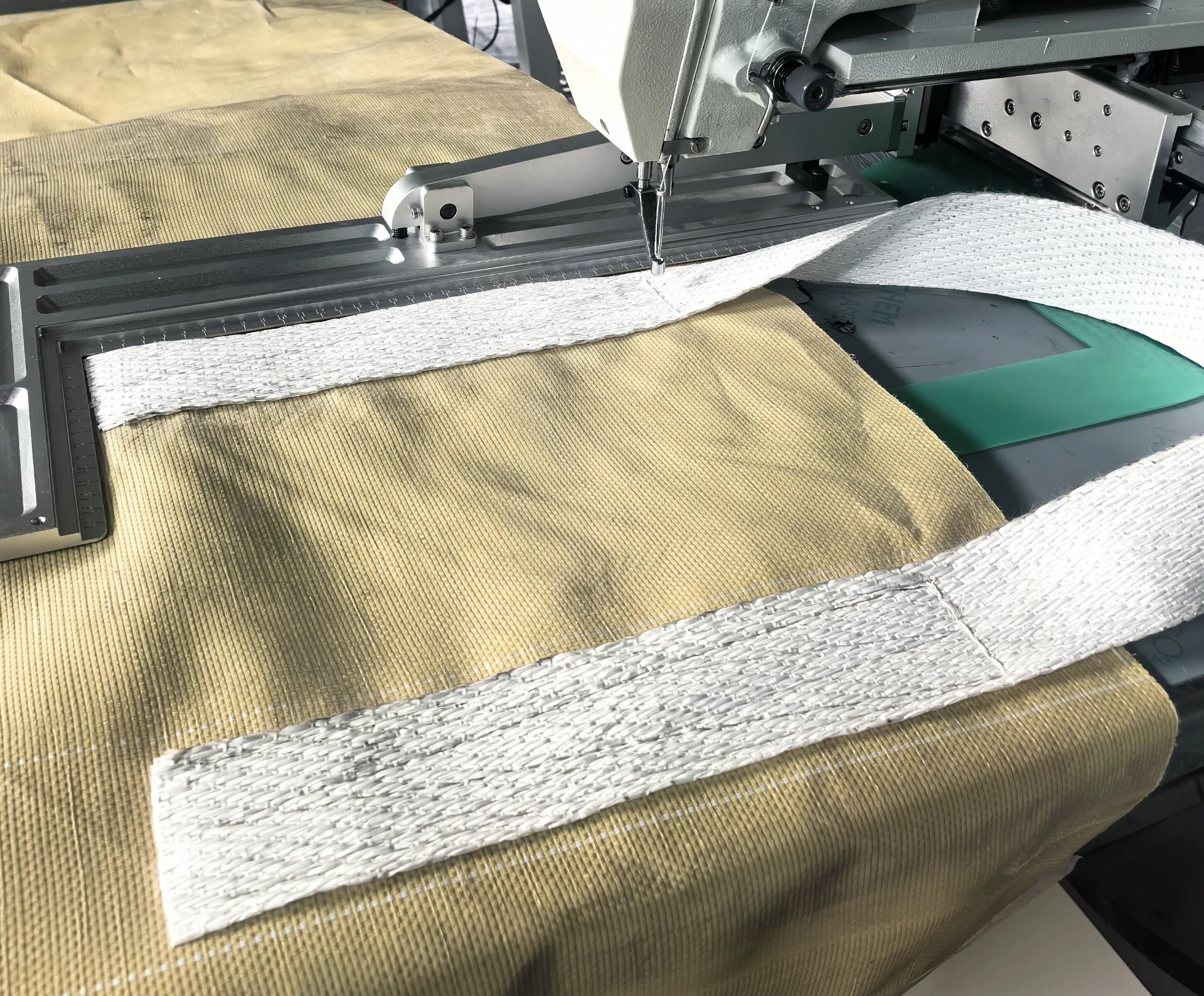

big bag sewing machine

The big bag sewing machine industry has seen significant advancements, offering solutions tailored for the bulk packaging sector. Understanding the intricacies of these machines can transform how businesses handle large-scale packaging needs, setting a new standard in efficiency and reliability.

The evolution of these machines speaks volumes about their authoritativeness in the bulk packaging domain. Major companies, across industries such as agriculture, construction, and pharmaceuticals, have relied heavily on these machines to uphold their packaging standards. Given the heavy-duty nature of their tasks, the machines' consistent performance establishes them as indispensable assets in large-scale operations. Trustworthiness is a critical factor when considering investment in such machinery. Top manufacturers ensure that every machine undergoes rigorous testing and quality assurance procedures. This testing covers a variety of scenarios, ensuring that the machines can operate faultlessly under different conditions. Businesses, therefore, can trust these machines to deliver beyond expectations, often noting reduced downtimes and lower maintenance costs as clear benefits. In conclusion, big bag sewing machines stand as a testament to how experience, expertise, authoritativeness, and trustworthiness come together to create superior industrial solutions. For businesses seeking to enhance their packaging processes, investing in a high-quality big bag sewing machine is not just a purchase—it's a commitment to excellence in production efficiency and product handling. As technology advances, these machines will undoubtedly continue to evolve, offering even greater capabilities and setting new benchmarks in the packaging industry.

The evolution of these machines speaks volumes about their authoritativeness in the bulk packaging domain. Major companies, across industries such as agriculture, construction, and pharmaceuticals, have relied heavily on these machines to uphold their packaging standards. Given the heavy-duty nature of their tasks, the machines' consistent performance establishes them as indispensable assets in large-scale operations. Trustworthiness is a critical factor when considering investment in such machinery. Top manufacturers ensure that every machine undergoes rigorous testing and quality assurance procedures. This testing covers a variety of scenarios, ensuring that the machines can operate faultlessly under different conditions. Businesses, therefore, can trust these machines to deliver beyond expectations, often noting reduced downtimes and lower maintenance costs as clear benefits. In conclusion, big bag sewing machines stand as a testament to how experience, expertise, authoritativeness, and trustworthiness come together to create superior industrial solutions. For businesses seeking to enhance their packaging processes, investing in a high-quality big bag sewing machine is not just a purchase—it's a commitment to excellence in production efficiency and product handling. As technology advances, these machines will undoubtedly continue to evolve, offering even greater capabilities and setting new benchmarks in the packaging industry.

Previous:

Next:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025