big bag sewing machine

The Big Bag Sewing Machine Revolutionizing Crafting and Production

In the world of textile and fabric industries, efficiency and precision are paramount. The introduction of specialized equipment is crucial in enhancing productivity while ensuring quality output. One such groundbreaking innovation is the big bag sewing machine, a marvel that has transformed the manufacturing of bulk bags used in various sectors, including agriculture, construction, and packaging.

Understanding Big Bag Sewing Machines

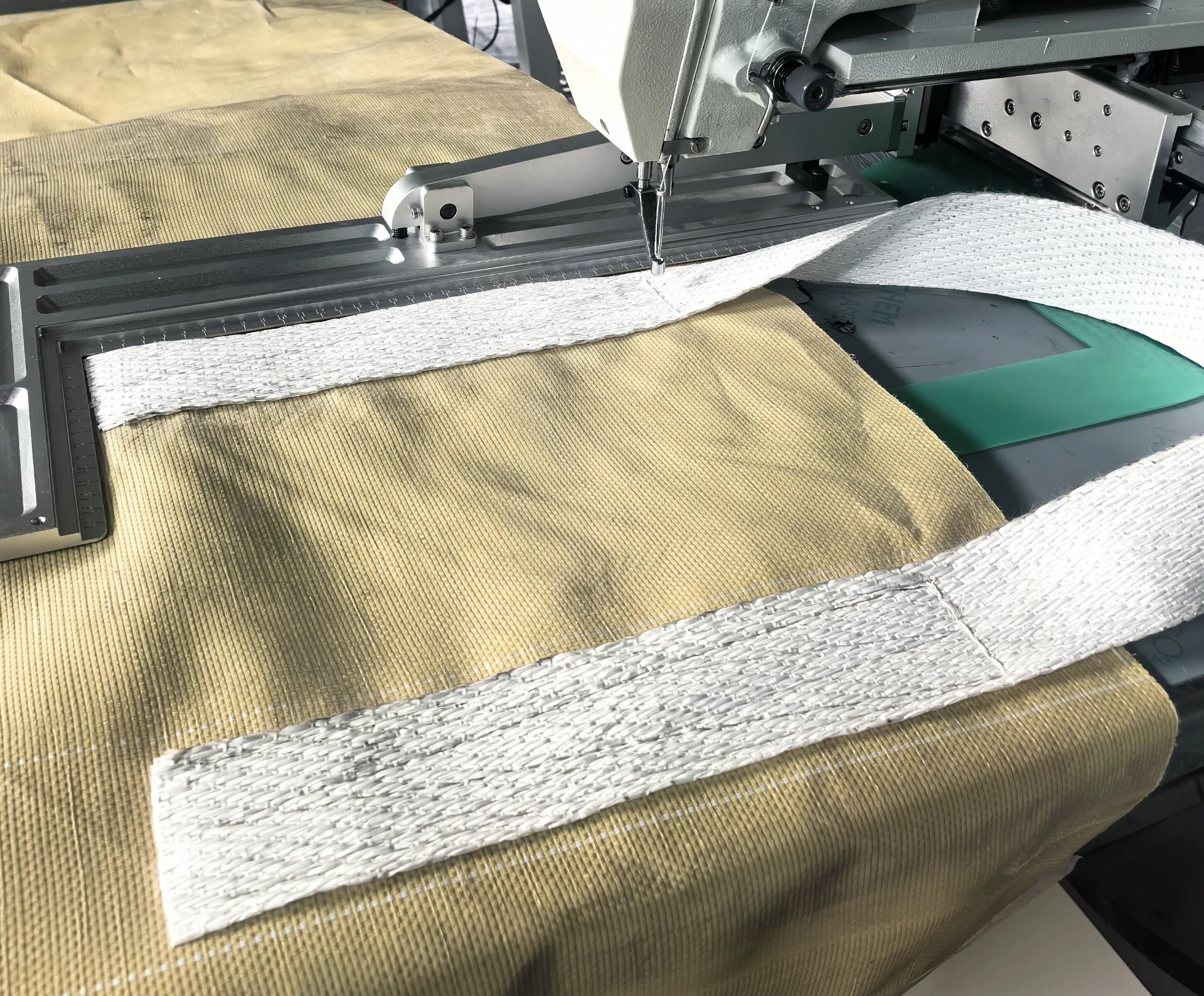

Big bag sewing machines are designed specifically for stitching large bags, often referred to as FIBCs (Flexible Intermediate Bulk Containers) or big bags. These bags are used for the bulk storage and transportation of materials such as sand, fertilizer, grain, and chemicals. The sewing machine’s capability to handle thick, heavy-duty fabrics such as polypropylene or woven fabrics makes it ideal for producing these robust bags.

The operation of a big bag sewing machine is relatively straightforward, yet it incorporates advanced technology to enhance its functionality. The machines come equipped with large needles and heavy-duty threads to ensure strong seams, thus providing the necessary durability for the bags. Additionally, many models feature automatic or semi-automatic functions that allow for faster production times and reduced labor costs.

Efficiency and Productivity

One of the standout features of big bag sewing machines is their ability to boost production efficiency significantly. Traditional sewing methods can be time-consuming, especially when dealing with large volumes. A big bag sewing machine can sew multiple bags in a fraction of the time it would take with manual sewing techniques. This efficiency translates directly to higher productivity levels for manufacturers, enabling them to meet market demands swiftly.

Moreover, with the increase in global trade, the need for reliable bulk packaging solutions has surged. Big bag sewing machines cater to this demand by allowing manufacturers to produce high-quality bags at scale. Their speed and efficiency ensure that businesses can keep up with production schedules and meet customer needs promptly.

big bag sewing machine

Enhanced Quality Control

Quality control is a significant concern in any manufacturing process. With big bag sewing machines, maintaining consistent quality is more achievable. These machines are designed to provide uniform stitch lengths and secure seams, minimizing the chances of production defects. Moreover, many machines are equipped with monitoring systems that alert operators to any issues that may arise during the sewing process, allowing for immediate adjustments to be made.

In addition, the use of technology in big bag sewing machines also means enhanced precision. Most machines are programmed to handle specific bag designs and dimensions, ensuring that every bag produced meets predetermined specifications. This level of precision guarantees that the bags perform effectively, reducing the risk of failure during transportation or storage.

Versatility of Applications

The versatility of big bag sewing machines makes them an asset across various industries. They can be used to manufacture bags for agricultural products, construction materials, and even hazardous materials. The adaptability of these machines to work with different fabrics and bag sizes further solidifies their importance in the manufacturing sector.

Beyond their primary use, these machines can also incorporate additional features such as printing capabilities and integrated handling systems, making them a multi-functional tool for manufacturers. As businesses continue to seek ways to streamline their processes, the big bag sewing machine plays a vital role in achieving these goals.

Conclusion

In conclusion, the big bag sewing machine represents a significant advancement in the textile manufacturing industry. Its ability to increase production efficiency, ensure consistent quality, and adapt to various applications makes it an invaluable tool for manufacturers aiming to meet the challenges of a competitive market. As the demand for bulk packaging solutions continues to grow, investing in a big bag sewing machine is not just a choice but a necessity for businesses looking to thrive. By embracing this technology, manufacturers can enhance their operational capabilities, improve product quality, and ultimately, drive their success in an ever-evolving marketplace.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025