Large Capacity Secure Stitch for Bag Closure Solutions

The Big Bag Lock Stitch A Revolution in Seam Technology

In the world of textile and sewing, few innovations have had as much impact as the lock stitch. This deceptively simple sewing technique is the backbone of countless sewing projects, from household items to high-end fashion. Among the notable applications of this technique is in creating big bags, which require durability, strength, and reliability. The marriage of big bags with the efficiency of lock stitching represents a revolutionary step in both design and functionality.

Understanding the Lock Stitch Mechanism

The lock stitch is formed by two threads the top thread and the bobbin thread. The needle passes through the fabric, creating a loop that captures the bobbin thread. As the needle rises, the lock stitch is formed, securing the threads in place. This interlocking of threads is what produces a tight seam that can withstand significant tension and wear.

This is particularly important in big bag manufacturing, where the materials used—often heavy-duty fabrics like canvas or nylon—require a sewing technique that can endure daily usage. Whether it’s for gym bags, travel totes, or large shopping bags, the lock stitch ensures that these items last through rigorous handling.

The Advantages of Using Lock Stitch in Big Bags

1. Durability One of the primary reasons for utilizing lock stitches in big bags is their strength. The interlocking nature of the stitch creates a seam that won’t easily come undone. This is vital for bags designed to carry heavy loads or withstand the elements.

2. Aesthetic Appeal Lock stitches can be executed with precision, allowing for clean and professional-looking seams. This is crucial for fashion and designer bags, where appearance can significantly affect customer perception and brand image.

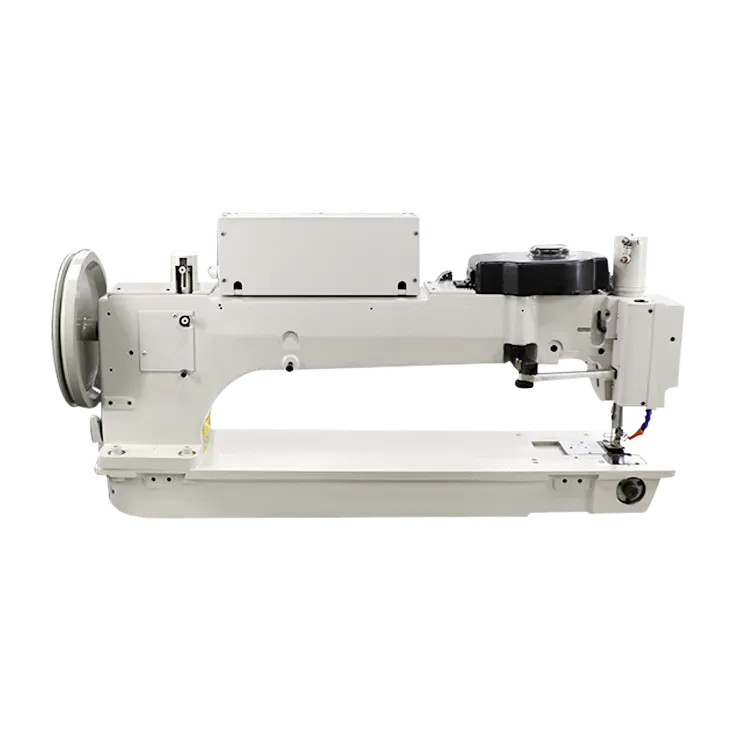

big bag lock stitch

3. Versatility The lock stitch is compatible with various types of fabric and can handle different thread types, making it suitable for a broad range of designs and styles in big bag manufacturing. This adaptability opens up numerous design possibilities, allowing creators to experiment with different materials and aesthetics.

4. Cost-Effective Production Thanks to advancements in sewing machines specifically designed for lock stitches, the production of big bags has become more efficient. High-speed sewing machines can produce stitches quickly and uniformly, reducing labor costs and increasing output without compromising quality.

5. Ease of Repair Should a seam become damaged, lock stitches are relatively straightforward to mend. The ability to repair and reinforce existing seams extends the life of a bag, which is an appealing feature for consumers who prioritize sustainability.

Innovations and Future Directions

With technological advances, the lock stitch continues to evolve. Automated sewing machines and robotic systems are making it possible to produce lock stitches with even greater precision and speed. Furthermore, the integration of smart technology into sewing practices is paving the way for innovative designs, where bags can be equipped with features like integrated charging ports or smart compartments.

Sustainability is also becoming a significant focus within the industry. Manufacturers are exploring eco-friendly materials and threads, ensuring that the production of big bags—from the lock stitch to the final product—aligns with environmentally conscious practices.

Conclusion

The big bag lock stitch epitomizes the perfect blend of function, durability, and aesthetic appeal. As technology continues to advance, the possibilities for innovation in bag manufacturing are limitless. This simple yet effective sewing technique will undoubtedly remain a cornerstone in the creation of bags that are not only practical but also stylish and sustainable. The future of big bags looks brighter with the lock stitch leading the charge.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025