Automated Tailoring Technology for Efficient and Precise Garment Production

The Evolution and Impact of Auto Tailoring Machines

In the world of fashion and garment manufacturing, innovation has played a crucial role in reshaping how clothing is produced. Among the most significant advancements in recent years is the development of auto tailoring machines. These state-of-the-art devices have revolutionized the tailoring process, optimizing efficiency, precision, and customization in ways that were previously unimaginable.

Understanding Auto Tailoring Machines

Auto tailoring machines are automated systems designed to assist in the creation of garments, reducing the need for extensive manual labor. These machines are capable of performing a variety of tasks, from cutting fabric to sewing intricate designs. By utilizing advanced technology such as computer-aided design (CAD), artificial intelligence, and robotics, auto tailoring machines ensure a higher degree of accuracy, minimizing errors that could otherwise occur in the traditional tailoring process.

These machines can produce clothing at a faster rate than human tailors, which is especially advantageous in large-scale production settings. Manufacturers can meet market demands more efficiently, responding to trends and consumer preferences almost in real-time. Furthermore, the incorporation of automated processes helps reduce the physical strain on workers, as heavy lifting and repetitive tasks can be delegated to machines.

Customization and Personalization

One of the most groundbreaking aspects of auto tailoring machines is their ability to facilitate customization. The rise of e-commerce has changed consumer expectations, with many individuals seeking unique clothing options that cater to their personal tastes. Auto tailoring machines can produce made-to-measure garments with precision, allowing customers to specify their measurements and design preferences.

This level of personalization has been made possible through advanced technological integration. For instance, some auto tailoring systems are linked directly to online platforms where customers can input their dimensions and desired styles. The machine then utilizes this data to create a tailored garment that fits perfectly. This shift toward personalized production not only enhances customer satisfaction but also sets brands apart in a competitive market.

Sustainability and Cost-Efficiency

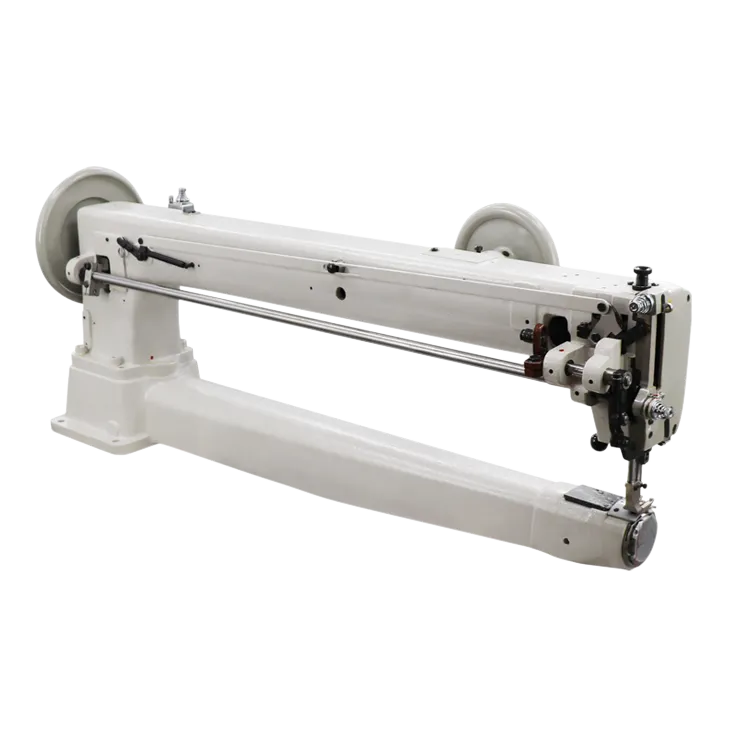

auto tailoring machine

As the fashion industry grapples with its environmental impact, auto tailoring machines also contribute to more sustainable practices. Traditional tailoring often results in significant fabric waste due to mismatched cuts and excess inventory. However, automated systems can optimize fabric usage, cutting patterns with minimal waste and using resources more efficiently.

Moreover, the cost-efficiency of auto tailoring machines cannot be overlooked. While the initial investment may be substantial, the long-term savings can be significant. Automated production reduces labor costs, speeds up production times, and minimizes waste, leading to lower overall expenses. These savings can be passed on to consumers, making high-quality, custom garments more accessible.

Challenges and the Future of Auto Tailoring

Despite the myriad advantages of auto tailoring machines, challenges remain. The initial costs associated with purchasing and maintaining these advanced systems can be prohibitive for smaller businesses. Additionally, there is a learning curve for operators unfamiliar with this technological landscape. Training staff to use these machines efficiently is essential to harnessing their full potential.

Furthermore, the rise of automation raises concerns regarding job displacement. While these machines enhance productivity, they also threaten traditional jobs in tailoring. The industry must balance technological advances with the need to provide job security for skilled workers.

Looking towards the future, the potential of auto tailoring machines seems limitless. As technology continues to evolve, so will the capabilities of these machines. Integration with artificial intelligence could lead to smarter systems that predict fashion trends and consumer desires, producing garments that align precisely with market demands.

Conclusion

Auto tailoring machines represent a significant leap forward in the garment manufacturing process. They enhance efficiency, precision, and customization, while also promoting sustainable practices. As the fashion industry continues to evolve in response to consumer demands and technological advancements, the auto tailoring machine will undoubtedly play a pivotal role in shaping the future of fashion production. Balancing innovation with ethical considerations will be crucial in ensuring that this technological leap benefits both businesses and the workforce.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025