Advanced Automated Dress Stitching Technology for Seamless and Efficient Garment Production

The Evolution of Automatic Dress Stitching Machines

In the ever-evolving world of fashion and garment manufacturing, the introduction of technology has transformed traditional practices into innovative solutions that enhance efficiency and creativity. One of the most remarkable advancements in this realm is the automatic dress stitching machine, a device that has revolutionized the way garments are produced and tailored.

The Historical Context

Historically, sewing was a labor-intensive process that required skilled artisans to create garments by hand. The advent of the sewing machine in the 19th century marked a significant turning point, significantly reducing the time and effort needed for construction. However, sewing machines were often limited in functionality and required a high level of manual input. It wasn't until the 21st century that automatic dress stitching machines began to emerge, integrating automation and artificial intelligence to streamline the sewing process.

How Automatic Dress Stitching Machines Work

Automatic dress stitching machines operate using advanced algorithms and robotics to execute sewing tasks with precision. These machines are equipped with computer-controlled systems that allow them to follow intricate patterns and designs, ensuring consistent and high-quality results. The machines can automatically adjust tension, stitch length, and speed based on the fabric type and thickness, minimizing the risk of errors and fabric damage.

Key features of these machines include multi-functional sewing heads, automatic threading systems, and the ability to interface with design software. This integration allows designers to upload digital patterns directly to the machine, where the stitching process can begin automatically. By reducing the need for manual intervention, these machines not only increase productivity but also free up skilled labor for more creative tasks within the design process.

Benefits to the Fashion Industry

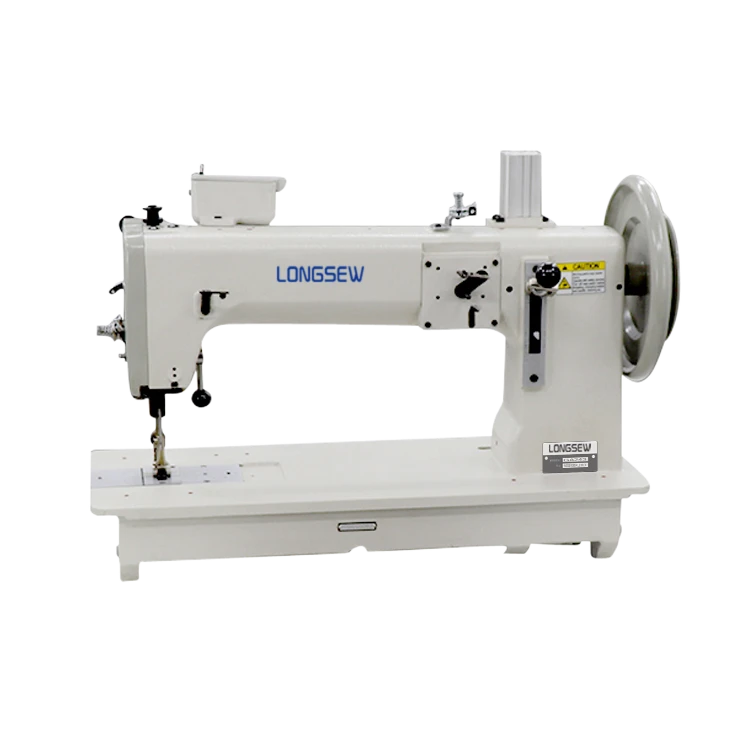

automatic dress stitching machine

The introduction of automatic dress stitching machines has had profound implications for the fashion industry. Firstly, they significantly reduce production time. What once took hours or days can now be accomplished in a fraction of the time, enabling manufacturers to respond quickly to market trends and consumer demands. This rapid turnaround is particularly vital in today’s fast-paced fashion environment, where the concept of “fast fashion” has become prevalent.

Secondly, these machines enhance precision in garment construction. Automatic stitch patterns ensure a uniform finish that is difficult to replicate by hand. This consistency not only improves the quality of the final product but also enhances brand reputation, as consumers increasingly seek reliable and well-made clothing.

Additionally, the sustainability of fashion production has greatly benefited from this technology. By optimizing fabric use and minimizing waste through precise cutting and stitching, automatic dress stitching machines contribute to a more sustainable manufacturing process. With growing awareness about environmental issues, brands that leverage such technologies stand to gain consumer trust and loyalty.

Challenges and Considerations

Despite their many advantages, the widespread adoption of automatic dress stitching machines is not without challenges. Initial costs can be prohibitive, especially for small-scale manufacturers or independent designers. Moreover, the reliance on automation raises concerns about job displacement within the industry. While these machines increase efficiency, it is essential to find a balance that preserves skilled labor while embracing technological advancements.

Furthermore, as fashion increasingly moves toward customization and personalization, the capabilities of automatic dress stitching machines must be continually upgraded. Manufacturers must ensure that their machines can handle bespoke requests while maintaining speed and accuracy.

Conclusion

Automatic dress stitching machines are a testament to the transformative power of technology in the fashion industry. By combining speed, precision, and sustainability, these innovative devices are changing the way garments are produced. As we move forward, it is crucial for the industry to adapt, embracing the potential of automation while also addressing the challenges that come with it. Ultimately, the goal should be to enhance creativity and craftsmanship, ensuring that fashion remains a vibrant and dynamic field for years to come. The future of garment manufacturing looks promising, and automatic dress stitching machines are at the forefront of this revolution.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025