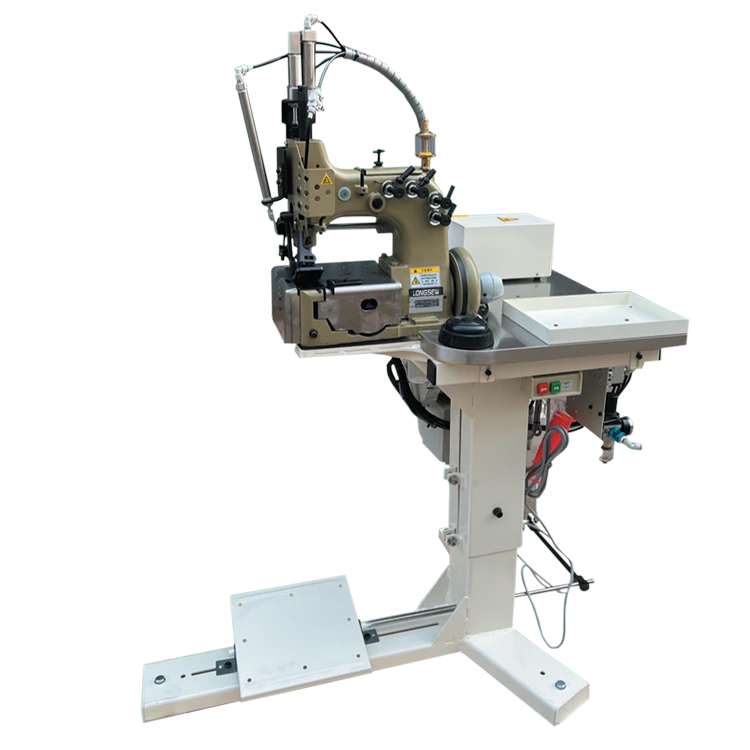

upholstery binding machine

The Evolution and Importance of Upholstery Binding Machines

Upholstery binding machines play a critical role in the upholstery industry, allowing manufacturers to create high-quality products with efficiency and precision. These machines have significantly evolved over the years, offering advanced functionalities that improve the quality of upholstery work while speeding up production times.

The Role of Upholstery Binding Machines

Upholstery binding machines are designed to apply binding to the edges of fabrics, ensuring a clean and durable finish. This process not only enhances the aesthetic appeal of furniture but also improves its longevity. The binding helps prevent fraying and provides a polished look that is crucial in the competitive upholstery market. As consumers become increasingly quality-conscious, the demand for well-finished upholstery has risen, making these machines an integral part of the production process.

Historical Overview

The evolution of upholstery binding machines can be traced back to the early 20th century when manual sewing techniques dominated the industry. Skilled craftsmen would painstakingly bind edges by hand, a labor-intensive process that required significant time and expertise. As industrialization progressed, the introduction of sewing machines revolutionized the upholstery trade, allowing for more efficient production.

By the mid-20th century, specialized binding machines began to emerge, focusing on the specific needs of upholstery. These machines utilized advanced needle techniques and specialized settings for various fabric types, greatly improving the binding process's speed and accuracy. Such innovations catered to mass production needs, enabling companies to keep up with increasing consumer demand.

Technological Advancements

upholstery binding machine

Today, upholstery binding machines are equipped with cutting-edge technologies that further enhance their functionality. Modern machines feature automatic feeding systems, allowing for continuous operation and minimal manual intervention. This automation significantly reduces the time required for binding operations, increasing overall productivity.

Another notable advancement is the integration of computer-driven controls, which enable precise adjustments to stitch length, tension, and speed. These features allow manufacturers to cater to different fabric types and binding styles without the need for extensive manual setup, thereby improving flexibility in production. Furthermore, some machines come with built-in design software, allowing upholsterers to create custom bindings tailored to specific projects, thus expanding creative possibilities.

Environmental Considerations

As environmental concerns continue to rise, upholstery binding machine manufacturers have also taken steps towards sustainability. Many models now use energy-efficient motors that consume less electricity, while waste reduction initiatives are implemented through optimized cutting and binding techniques. Eco-friendly materials are also increasingly used in the manufacturing of both the machines and the bindings themselves, allowing companies to meet the growing preference for sustainable practices within the upholstery industry.

Conclusion

The upholstery binding machine is an essential tool that not only enhances the visual appeal of furniture but also ensures its durability and longevity. From simple manual techniques to advanced automated systems, the evolution of these machines reflects the broader changes within the upholstery industry. As technology continues to advance, upholstery binding machines will likely become even more sophisticated, offering greater efficiency and quality.

In conclusion, the importance of upholstery binding machines cannot be overstated. They bridge the gap between artistry and functionality in upholstery production. By embracing modern technologies and sustainable practices, manufacturers can meet the demands of today’s consumers while ensuring that their products remain competitive in the marketplace. As the industry continues to evolve, so too will the capabilities of upholstery binding machines, contributing to the art and craft of upholstery for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025