single needle post bed sewing machine

Understanding the Single Needle Post Bed Sewing Machine

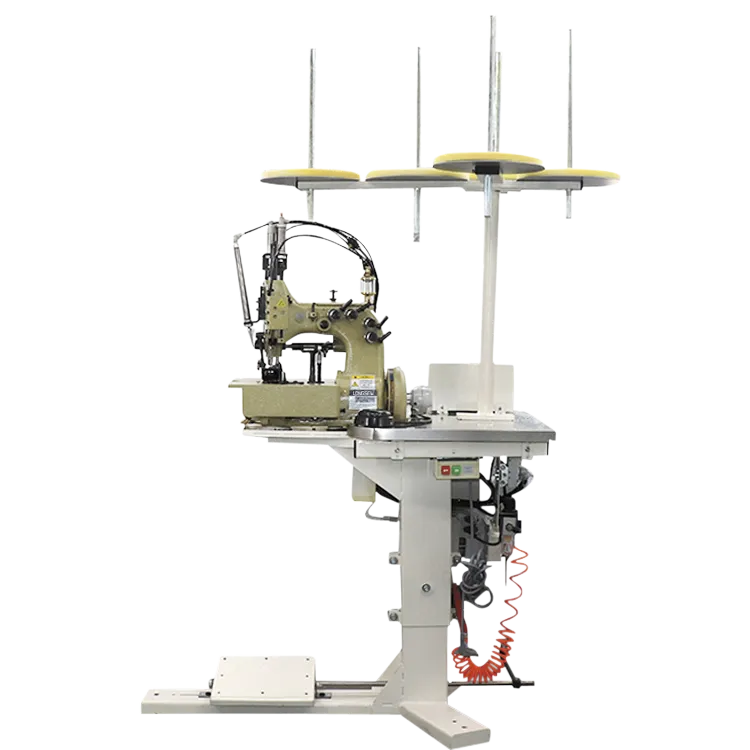

The single needle post bed sewing machine is an essential tool in the world of industrial sewing, particularly favored for its versatility and efficiency in handling various sewing tasks. Commonly used in garment manufacturing, leather goods, upholstery, and other applications, this machine has gained a reputation for its precision and ability to navigate challenging stitching requirements.

Design and Features

At the heart of the single needle post bed sewing machine is its unique construction. The post bed design elevates the needle and presser foot above the sewing table, allowing for easy manipulation of bulky materials such as leather and thick fabrics. This vertical post structure accommodates oversized items while maintaining stability and control during the sewing process. The single needle configuration provides a straight stitch, which is ideal for a wide range of sewing applications, from simple seams to complex patterns.

One of the distinguishing features of the single needle post bed machine is its ability to create strong, durable stitches. This is especially important in industries where the end product must withstand significant wear and tear, such as in the production of bags, belts, and other leather items. The machine typically operates at high speeds, which increases productivity while maintaining stitch quality.

Versatility in Applications

The versatility of the single needle post bed sewing machine is one of its most significant advantages. This machine can handle various materials, including cotton, polyester, nylon, and leather. As a result, it is widely employed in multiple sectors, including fashion, automotive, marine, and home furnishings. The ability to adjust settings for different types of fabric and thickness makes it an indispensable tool for manufacturers.

single needle post bed sewing machine

Additionally, the single needle post bed machine often comes equipped with various optional features, such as automatic needle positioning, thread trimming, and programmable stitching patterns. These enhancements contribute to improved efficiency and ease of use, allowing operators to handle more complex tasks with minimal downtime.

Maintenance and Operation

Proper training and maintenance are crucial for maximizing the performance and longevity of a single needle post bed sewing machine. Regular oiling, cleaning, and inspection of parts such as the needle, feed dog, and bobbin area can prevent breakdowns and ensure smooth operation. Operators should also be familiar with the machine’s threading process and tension adjustments, as these factors significantly influence stitch quality.

Training programs and manuals are often available from manufacturers, helping users understand the machine’s capabilities and best practices for different sewing tasks. As with any specialized equipment, investing in training can lead to greater efficiency and better-quality finished products.

Conclusion

The single needle post bed sewing machine is a vital piece of equipment in the textile and leather industries. With its unique post bed design, versatility, and robust stitching capabilities, it effectively meets the demands of various sewing applications. Properly maintained and operated, this machine can significantly enhance productivity and output quality, making it a favored choice for manufacturers looking to optimize their sewing operations. As advancements in technology continue to evolve, the single needle post bed machine remains a cornerstone in the industrial sewing landscape, ensuring high standards of craftsmanship in every stitch.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025