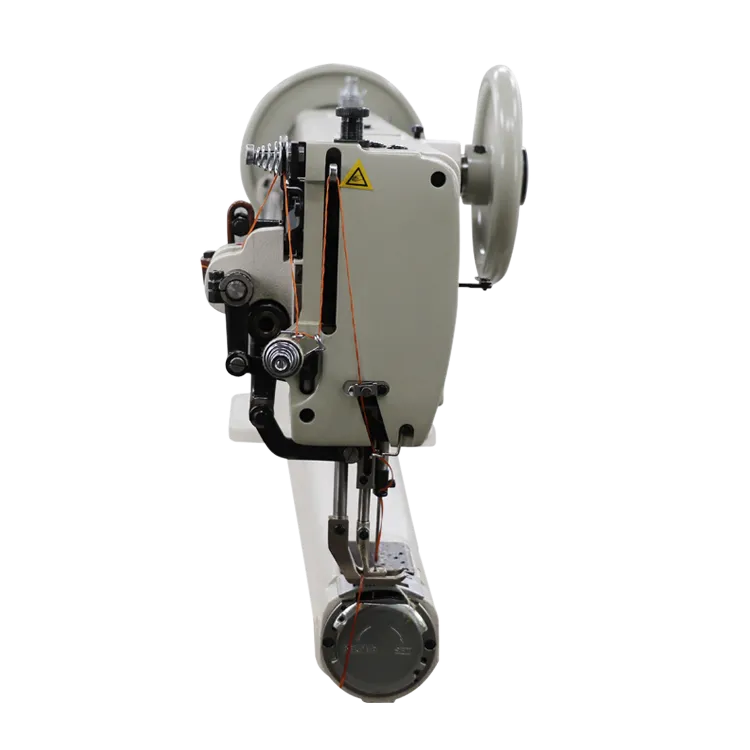

Single Needle Lockstitch Sewing Machine for Precision and Versatility in Textile Projects

The Evolution and Importance of the Single Needle Lockstitch Sewing Machine

The single needle lockstitch sewing machine is a pivotal tool in both the garment manufacturing industry and home sewing. This machine, celebrated for its reliability and precision, has been a cornerstone of textile production for over a century, evolving from its mechanical roots to sophisticated electronic models. Understanding the mechanisms, applications, and impact of this machine illuminates its significance in modern sewing practices.

The Mechanism Behind the Single Needle Lockstitch

At the heart of the single needle lockstitch sewing machine is its ingenious mechanism. The lockstitch itself is created by two threads the needle thread that is passed through the fabric and a bobbin thread that is turned up from below. This interlocking of threads forms a secure stitch, which is fundamental for constructing a wide range of fabric items, from clothing to home textiles. The needle moves up and down, allowing the thread to be pulled through the fabric, while the bobbin holds the lower thread in place, ensuring a neat finish on both sides of the material.

Early models of the single needle lockstitch machine relied on foot-powered mechanisms, but as technology progressed, electric machines became predominant. These newer models offer faster sewing speeds, built-in needle positioning, adjustable stitch lengths, and even programmable patterns, enhancing the efficiency and versatility required in modern textile production.

Applications of the Single Needle Lockstitch

The single needle lockstitch machine is incredibly versatile, making it suitable for various applications. It is extensively used in clothing manufacturing, where it helps produce garments with durable seams. Tailoring and designing are enhanced by the precision this machine offers, allowing for intricate detailing and custom fits.

Moreover, the machine is crucial in other areas such as upholstery, where heavy fabrics require sturdy stitching. Home sewers appreciate the lockstitch machine for its user-friendly operation and reliability, making it an ideal choice for DIY projects, quilting, and mending garments.

In addition to textiles, the machine finds applications in industries like automotive and leather goods, where high-strength seams are essential. Its adaptability to various materials and fabrics, such as denim, canvas, and linens, demonstrates its broad utility.

single needle lockstitch sewing machine

The Impact of Technology on Sewing

The advent of technology has transformed the single needle lockstitch machine into a highly sophisticated tool. Features such as computerized sewing functions, automatic threading, and built-in sensors have made these machines easier to use and more efficient. These advancements have drastically reduced production times while improving stitch quality.

Furthermore, electronic machines often include memory functions to save patterns, allowing for greater creativity and consistency in production. This progression has not only benefitted professional manufacturers but has also empowered hobbyists, allowing them to explore their creativity without the steep learning curve associated with more complex machines.

Challenges Within the Industry

Despite its many advantages, the sewing machine industry faces challenges. The shift toward automation in manufacturing processes has led to concerns about job displacement. However, it is important to acknowledge that while machines can streamline production, the artistry and skills of human workers remain irreplaceable. Trained seamstresses and tailors bring creativity, precision, and personalization to their work that machines cannot replicate.

Additionally, environmental concerns regarding waste and overproduction in the fashion industry highlight the need for sustainable practices. Many manufacturers are now focusing on producing high-quality garments with minimal waste, utilizing the capabilities of the single needle lockstitch machine to its fullest to enhance sustainability without compromising quality.

Conclusion

The single needle lockstitch sewing machine is an indispensable tool that has significantly impacted the textile industry. Its evolution from basic mechanical designs to advanced electronic machines showcases the interplay between tradition and technology. As the demands of the textile industry change, the single needle lockstitch machine continues to adapt, ensuring it remains a vital component in both professional and domestic sewing environments. The fusion of skilled craftsmanship and machine efficiency points towards a future where the art of sewing thrives amidst technological advancements, proving that innovation and tradition can coexist harmoniously.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025