Innovative Leather Machinery Solutions for Industrial Applications and Efficient Production Processes

The Role of Industrial Leather Machines in Modern Manufacturing

In the realm of manufacturing, the transformation of raw materials into finished products is a complex process that relies heavily on technology. Among the various machinery utilized in this field, industrial leather machines have carved a significant niche. These machines have revolutionized the way leather is processed, enhancing efficiency and quality while catering to the demands of a constantly evolving market.

Industrial leather machines are specialized equipment designed to handle the various stages of leather production. From tanning to cutting, stitching, and finishing, each machine plays a critical role in ensuring that the leather meets the exacting standards required for various applications, including fashion, automotive, and furniture industries. The advancement of technology has led to the development of sophisticated machines that not only improve productivity but also reduce environmental impact.

One of the primary types of industrial leather machinery is the tanning machine

. Tanning is a crucial step that converts animal hides into durable leather by preventing decay. Modern tanning machines employ advanced techniques, such as chrome tanning and vegetable tanning, to ensure a high-quality output while adhering to safety and environmental regulations. These machines have automated processes that enhance the consistency of the final product, reduce waste, and lower labor costs.Cutting machines are another essential component of leather processing. Traditionally, cutting was a manual task that required skilled artisans. However, today's automated cutting machines can precisely cut leather pieces according to specified patterns, significantly increasing accuracy and efficiency. Computer numerical control (CNC) technology allows for intricate designs that were once impossible to achieve, enabling manufacturers to produce complex products with ease.

industrial leather machine

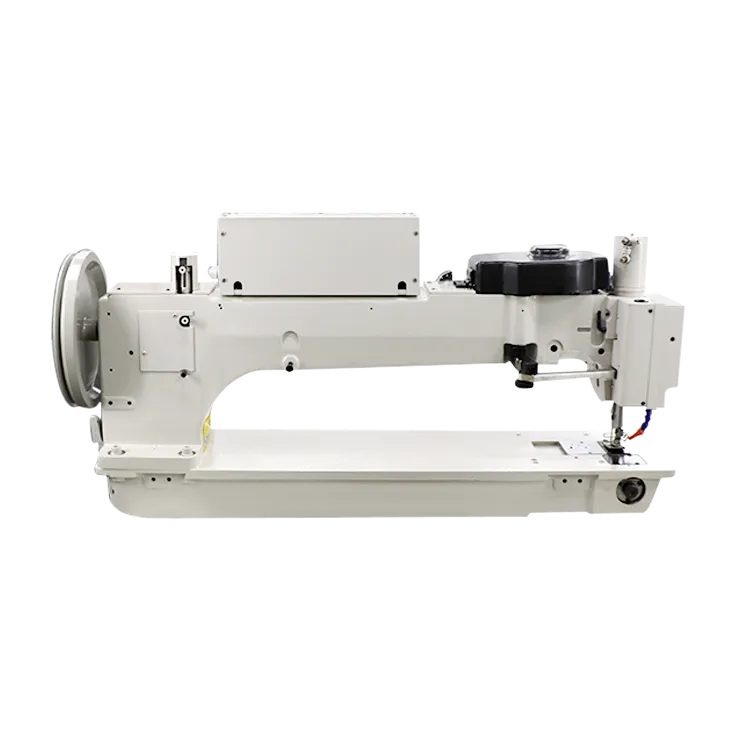

Sewing is equally vital in the leather manufacturing process. Industrial sewing machines are designed to handle the thickness and texture of leather, which can be challenging compared to other fabrics. These machines come equipped with specialized needles and presser feet that ensure even stitching and reduce the risk of damaging the material. Furthermore, advancements in technology have led to the creation of programmable sewing machines that can create intricate designs with minimal human intervention, thereby enhancing production rates.

Finishing processes have also been transformed by industrial leather machines. Finishing refers to the treatments applied to leather to improve appearance, durability, and resistance to environmental factors. This process may include dyeing, embossing, and applying protective coatings. Machinery designed for these purposes can provide a uniform finish, which is crucial for maintaining brand standards and consumer satisfaction.

One cannot overlook the growing importance of sustainable practices in leather manufacturing. The leather industry has faced scrutiny over environmental concerns, especially regarding water usage and chemical waste. To address these issues, manufacturers are increasingly investing in eco-friendly industrial leather machines equipped with technologies that minimize resource consumption and reduce pollution. Innovations such as closed-loop water systems and non-toxic tanning processes are becoming more prevalent, reflecting a shift towards sustainability in the industry.

In conclusion, industrial leather machines are an indispensable part of the leather manufacturing process. They drive efficiency, improve product quality, and facilitate sustainable practices. As technology continues to evolve, the future of these machines promises even greater advancements, offering exciting possibilities for manufacturers and consumers alike. The integration of automation and sustainability into leather processing not only enhances the operational capabilities of manufacturers but also helps meet the rising consumer demand for ethically produced goods. The journey of leather from raw hide to finished product is increasingly reliant on these remarkable machines, which will undoubtedly shape the future of the leather industry.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025