Industrial Cylinder Bed Sewing Machines: Precision & Durability

In the intricate world of industrial sewing, precision, durability, and adaptability are paramount. For manufacturers dealing with complex, three-dimensional, or bulky materials, the traditional flat-bed sewing machine often falls short. This is where the cylinder bed sewing machine emerges as an indispensable tool. Its unique design, featuring a narrow, cylindrical arm, allows operators to maneuver workpieces around the sewing area with unparalleled ease, making it the preferred choice for a wide array of specialized applications. From the robust seams in automotive upholstery to the intricate stitching on high-end leather goods, a cylinder bed sewing machine is engineered to deliver superior results where conventional machines cannot.

This comprehensive guide delves into the essence of these powerful machines, covering everything from their technological advancements and industry applications to the meticulous manufacturing processes that ensure their exceptional performance and longevity. We will explore the nuances of selecting the right machine, understanding key technical specifications, and even providing insights into market trends and the considerations for a cylinder bed sewing machine price, whether you're looking for a new model or a cylinder bed sewing machine for sale. We will also touch upon the capabilities of heavy-duty machines like the Extra Heavy Duty Top & Bottom Feeding Flat Bed Sewing Machine GA733/GA733-L30, which, while a flat bed, shares many robust features and application overlaps with its cylinder bed counterparts in handling challenging materials.

Industry Trends and the Evolving Landscape of Industrial Sewing

The industrial sewing machine market is dynamic, driven by innovation and the growing demand for specialized products. Key trends influencing the adoption and development of the cylinder bed sewing machine include:

- Automation and Smart Integration: Modern machines are increasingly incorporating servo motors for precise speed control and energy efficiency, programmable stitch patterns, and even IoT capabilities for remote monitoring and diagnostics. This reduces operator fatigue and increases output consistency, aligning with Industry 4.0 principles.

- Sustainable Manufacturing: A growing focus on reduced energy consumption, minimized waste, and the use of eco-friendly materials in machine construction and operation is becoming a priority. Manufacturers are designing machines that are more durable and require less frequent part replacement, contributing to a circular economy.

- Advanced Material Handling: As industries use more complex, multi-layered, and synthetic materials (e.g., carbon fiber composites, technical textiles, ballistic nylons), the need for sophisticated feeding mechanisms like compound feed (walking foot, needle feed, bottom feed) in a cylinder bed sewing machine becomes crucial. These systems ensure consistent feeding without material slippage or distortion, even on challenging textures.

- Ergonomics and Operator Comfort: Designs are evolving to enhance operator comfort and reduce repetitive strain injuries. Features like adjustable tables, improved lighting, and intuitive control panels contribute to higher productivity and lower operational costs in the long run.

- Global Supply Chain Diversification: The market sees an increase in regional manufacturing hubs and a greater focus on resilience in supply chains, which influences the availability and pricing, including the cylinder bed sewing machine price. Brands like Jack cylinder bed sewing machine are prominent examples in various markets due to their widespread availability and competitive offerings.

Technical Parameters and Specifications: Understanding Your Machine

Choosing the right cylinder bed sewing machine hinges on a thorough understanding of its technical specifications. These parameters directly influence the machine's capability to handle specific materials and sewing tasks effectively, ensuring optimal performance and product quality.

Key Components and Functions:

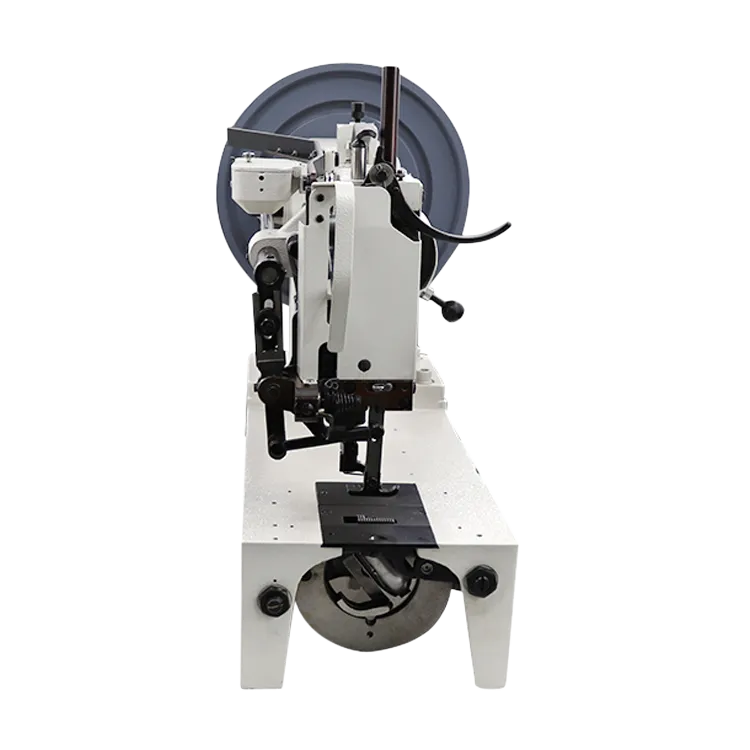

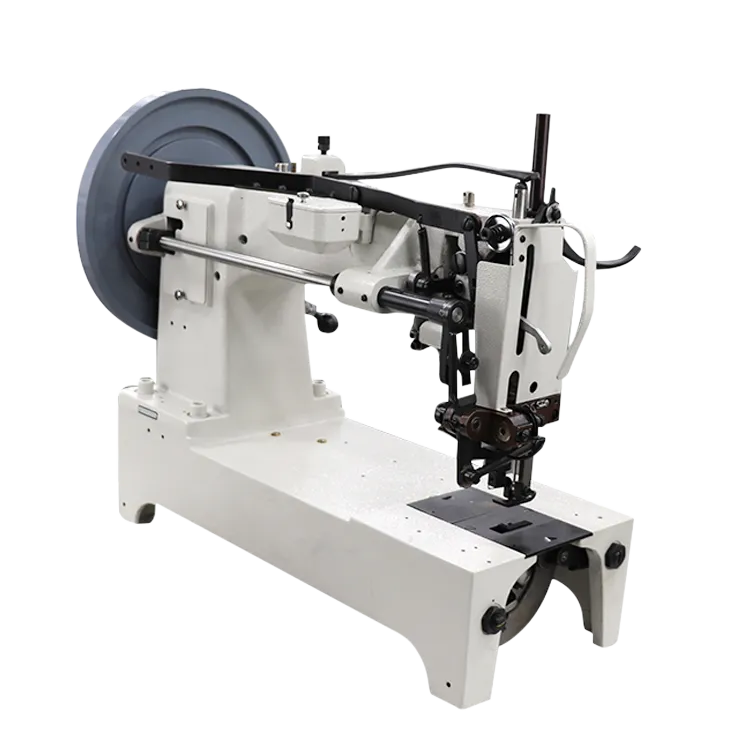

- Cylinder Arm: The defining feature of a cylinder bed sewing machine. This narrow, extended arm allows the sewing of tubular or curved items like bags, shoes, and automotive parts. The diameter and length of the arm vary based on application, with smaller diameters suitable for tighter curves (e.g., wallet corners) and larger for bulkier items (e.g., boat covers).

- Feeding Mechanism: Crucial for consistent stitch quality on heavy materials, preventing material slippage or distortion.

- Bottom Feed: The most basic feed system where a toothed feed dog moves the fabric from below. Suitable for light to medium materials.

- Needle Feed: The needle moves horizontally with the feed dog, actively assisting in pulling the fabric. This reduces ply shifting, especially on synthetic materials.

- Walking Foot (Top Feed): An additional independent presser foot moves along with the needle and feed dog, ensuring all layers are fed evenly from the top. This is essential for thick, slippery, or multi-layered materials, effectively "walking" over the fabric. This robust feeding system is a key feature in many heavy-duty machines, including the Extra Heavy Duty Top & Bottom Feeding Flat Bed Sewing Machine GA733/GA733-L30.

- Unison/Compound Feed: Combines walking foot, needle feed, and bottom feed for unparalleled material handling and consistent stitch length on challenging fabrics. This synchronized movement minimizes the potential for inconsistent stitches or fabric bunching on bulky items.

- Hook System: Determines bobbin capacity and stitch formation. Large rotary hooks (often referred to as "Jumbo" or "X-Large" bobbins) are common in heavy-duty machines for fewer bobbin changes, which translates to less downtime and higher productivity during long sewing runs. The hook mechanism also dictates the type of stitch (e.g., lockstitch).

- Stitch Length: Adjustable to accommodate different thread sizes and material thicknesses. A longer stitch length typically indicates a machine's capacity for heavier materials and provides a stronger seam, often ranging from 6mm to 15mm for heavy-duty applications.

- Presser Foot Lift: The maximum height the presser foot can be raised, indicating the maximum material thickness the machine can accommodate under the needle. For heavy-duty machines, a high lift (e.g., 15mm-25mm via knee lift or foot pedal) is critical for easily positioning bulky workpieces.

- Motor Type: Modern industrial machines primarily use servo motors, offering variable speed control, quiet operation, and significant energy efficiency (up to 70% energy savings compared to older clutch motors, according to industry benchmarks like those provided by the Industrial Sewing Machine Manufacturers Association). Clutch motors, while still available, provide high torque but are less efficient and louder.

Comparative Data: Typical Heavy-Duty Industrial Sewing Machine Parameters

The table below provides a general overview of parameters found in various heavy-duty industrial sewing machines, including those that are cylinder bed sewing machine or robust flat-bed models like the GA733/GA733-L30. These figures are indicative and vary by specific model and manufacturer, reflecting the diverse needs of industrial sewing.

| Parameter | Typical Range for Heavy-Duty Machines | Relevance for Cylinder Bed Sewing Machine / GA733/GA733-L30 |

|---|---|---|

| Max. Stitch Length | 6 - 15 mm (Adjustable) | Allows for strong, prominent stitches on thick materials like canvas, leather, or synthetic webbing. Longer stitches indicate higher capacity for heavy threads and greater seam strength required for durable goods. |

| Max. Sewing Speed | 800 - 2500 stitches/min | Lower speeds are typical for extra heavy-duty machines to ensure precise penetration and control on very thick materials, preventing needle deflection or thread breakage. High-speed options are for less dense materials. |

| Presser Foot Lift (Manual/Knee) | 13 - 25 mm | Critical for accommodating bulky and multi-layered materials easily. The GA733/GA733-L30, for instance, offers significant lift to manage its intended heavy-duty applications. |

| Needle System | DPx17, DPx17 LR (Leather Point), 7x3, 794 (for very heavy threads) | Specific needles designed for heavy fabrics and leather, often with special points (e.g., chisel or wedge point for leather) to penetrate without tearing fibers. |

| Thread Size Capacity | Tex 70 - Tex 350 (or V69 - V346) | Indicates the range of heavy threads the machine can handle, essential for creating strong seams in demanding applications like safety equipment, automotive, and marine products. |

| Bobbin Type | Large Capacity Rotary Hook (Jumbo, X-Large) | Minimizes downtime for bobbin changes, crucial for efficiency when using thick threads and on long production runs. |

| Cylinder Arm Diameter (for Cylinder Beds) | 50 - 80 mm | Smaller diameters allow for sewing tighter curves and smaller items; larger for bulkier but less intricate shapes (e.g., luggage). |

| Motor Power | 550W - 750W (Servo Motor) | Sufficient power for penetrating multiple layers of dense materials consistently without stalling. Servo motors also offer precise control and energy efficiency. |

| Lubrication System | Automatic/Semi-automatic | Ensures continuous and adequate lubrication of critical moving parts, prolonging machine life and reducing maintenance frequency. This is vital for high-performance industrial machines. |

| Net Weight (Head Only) | 35 - 70 kg | Heavier machines often indicate more robust construction with higher-density materials, leading to greater stability, less vibration, and improved stitch consistency during heavy-duty operation. |

Manufacturing Process of a High-Performance Industrial Sewing Machine

The creation of a high-performance cylinder bed sewing machine or heavy-duty flat-bed model like the GA733/GA733-L30 is a testament to precision engineering, material science, and stringent quality control. Every component, from the smallest screw to the main chassis, undergoes a rigorous manufacturing journey to ensure decades of reliable operation under demanding industrial conditions.

Manufacturing Process Overview

This process highlights the meticulous steps involved in producing a durable and precise industrial sewing machine, adhering to the highest industry standards.

Material Selection & Procurement

Product Material: The foundation of durability lies in material choice. High-grade cast iron (e.g., FC250-FC300, equivalent to ASTM A48 Class 35-40 in the US, or EN-GJL-250 in Europe) is selected for the machine's main body and cylinder arm components due to its exceptional vibration dampening properties, high compressive strength, and inherent rigidity. For critical moving parts like gears, shafts, connecting rods, and cam mechanisms, hardened steel alloys (e.g., Chromium-Molybdenum alloy steel like 40CrMo, or bearing steel such as GCr15, equivalent to AISI 52100) are chosen for their superior wear resistance, tensile strength, and fatigue limit. Precision bearings from globally recognized suppliers (e.g., SKF, NSK, FAG) are integrated to ensure smooth, low-friction operation and extend component life. All fasteners meet international standards like ANSI/ASME, DIN, or JIS for reliability and interchangeability.

Primary Component Forming (Casting & Forging)

Casting: The main frame, cylinder arm, and other large structural components are typically produced through advanced sand casting or investment casting methods. This ensures a robust, unitary structure capable of withstanding high operational stresses and minimizing machine deflection during intense use. After initial casting, components undergo an annealing process, a heat treatment that relieves internal stresses and improves machinability, preventing future warping or cracking.

Forging: Smaller, high-stress parts that require exceptional strength, impact resistance, and fatigue endurance, such as connecting rods, certain levers, and gear blanks, are hot-forged. Forging mechanically deforms the metal, refining its grain structure and eliminating internal voids, which dramatically enhances its mechanical properties and ensures structural integrity for the most demanding parts.

Precision Machining (CNC Machining)

Components from the casting and forging stages are then subjected to state-of-the-art CNC (Computer Numerical Control) machining. This stage is paramount for achieving the extremely tight tolerances (often within micrometers or 0.001mm) and complex geometries required for seamless machine operation. Multi-axis CNC machines precisely mill, bore, turn, and grind surfaces that interface with other parts or moving mechanisms. This ensures perfect fit, smooth movement, minimal friction, and precise timing. Examples include the precise bore for the needle bar, the mirror-smooth surface of the hook race, and the exact seating for bearings. Automated robotic machining arms are often utilized to maintain consistency and high throughput.

Heat Treatment & Surface Finishing

Following machining, many steel components undergo specialized heat treatments to enhance their performance characteristics. Processes like carburizing (adding carbon to the surface for hardness), nitriding (introducing nitrogen for wear and corrosion resistance), or induction hardening (localized hardening using electromagnetic induction) are employed. This significantly increases the surface hardness and wear resistance of critical parts like gears, shafts, hooks, and feed dogs, extending their operational lifespan and maintaining optimal performance under high loads. Subsequently, various surface finishes, such as chrome plating (for corrosion resistance and aesthetics), black oxide (for corrosion resistance and reduced glare), or phosphating, are applied to further protect components, reduce friction, and improve overall durability.

Assembly & Lubrication Systems

In meticulously controlled cleanroom environments, highly skilled technicians meticulously assemble thousands of components. Precision alignment and calibration are key to ensuring smooth operation, consistent stitch quality, and minimal vibration. High-end machines feature advanced automatic lubrication systems. These systems utilize precisely calibrated oil pumps and wicks to ensure continuous and adequate oil flow to all critical moving parts, effectively reducing wear, dissipating heat, and extending maintenance intervals. This proactive lubrication is vital for machines like the GA733/GA733-L30, which are designed for continuous, high-volume heavy-duty use, ensuring sustained performance and longevity.

Rigorous Testing & Quality Assurance

Each machine undergoes multi-stage, comprehensive testing before leaving the factory.

- Component-level inspection: Includes dimensional checks using CMM (Coordinate Measuring Machines), material analysis, hardness testing (e.g., Rockwell, Vickers), and surface roughness measurements.

- Sub-assembly testing: Ensuring proper function of critical modules like feeding mechanisms, hook timing, needle bar movement, and thread tensioning systems in isolation.

- Full machine run-in test: Every finished machine is subjected to a continuous run-in period (often several hours or even days) under load, frequently using typical application materials (e.g., thick leather or multi-layered canvas). During this phase, performance metrics such as stitch quality, noise levels, vibration, heat generation, and precise stitch formation are carefully monitored and logged.

Application Scenarios and Industry Advantages

The versatility and strength of a cylinder bed sewing machine make it indispensable across a wide range of industries, especially those dealing with complex shapes, thick materials, or products with pre-formed structures. While the GA733/GA733-L30 is technically a flat-bed machine, its heavy-duty top and bottom feeding capabilities mean it addresses many similar challenges in material handling, focusing on consistent, powerful feeding for very thick, multi-layered fabrics.

Typical Application Areas:

- Leather Goods Manufacturing: Crucial for crafting high-end leather bags, wallets, belts, briefcases, saddlery, and equestrian equipment. The cylinder arm is perfectly suited for sewing the curved edges of bag components, the intricate designs on horse saddles, or attaching handles to three-dimensional items.

- Automotive Upholstery: Essential for stitching complex components of car seats, dashboards, steering wheel covers, door panels, and airbags. The ability to maneuver the workpiece around contoured shapes ensures perfectly finished, durable interiors that meet strict automotive safety and aesthetic standards.

- Marine & Outdoor Canvas: Used extensively for sewing boat covers, bimini tops, sails, awnings, tents, and heavy-duty tarpaulins. These materials are often heavy, UV-resistant, water-resistant, and require strong, weather-proof seams that can withstand harsh outdoor elements.

- Luggage & Backpacks: Indispensable for assembling durable suitcases, travel bags, duffel bags, and specialized backpacks where robust construction and the ability to sew around corners and edges are critical for product longevity.

- Footwear Industry: Widely employed in shoe manufacturing for stitching shoe uppers, especially around curved parts, attaching soles, or where thick leather or synthetic materials are involved, demanding strong, consistent seams.

- Technical Textiles & Protective Gear: Critical for manufacturing industrial slings, safety harnesses, lifting straps, medical braces, tactical gear, ballistic vests, and specialized filtration systems. These applications often involve multi-layered, abrasive, high-strength, or composite materials that demand superior penetration power and consistent stitch formation.

- Furniture Upholstery: Especially for sofa arms, curved cushions, and other three-dimensional upholstered elements that are difficult to handle effectively on a standard flat-bed machine, allowing for precision and tight curves.

Regarding the less common applications mentioned in the prompt (petrochemical, metallurgy, water supply & drainage): While these machines are not directly used in the core processes of these industries (e.g., sewing a pipe while it's in a refinery), they are absolutely crucial for manufacturing products *used by* these industries. For instance:

- Petrochemical & Metallurgy: Production of heavy-duty personal protective equipment (PPE) like fire-resistant suits, welding aprons, high-temperature gloves, and specialized filters that require robust, heat-resistant stitching on thick, technical fabrics designed for extreme environments. These machines ensure the integrity of life-saving gear.

- Water Supply & Drainage: Fabrication of large-scale filtration bags for industrial water treatment, geotextiles for erosion control and filtration in civil engineering projects, and flexible pipes or bladder tanks that demand strong, durable, and often sealed seams to withstand harsh environmental conditions, chemicals, and pressure. The precision of a cylinder bed sewing machine ensures these critical components perform reliably.

Product Advantages in Application (GA733/GA733-L30 - Extra Heavy Duty Top & Bottom Feeding Flat Bed Sewing Machine):

While primarily a flat-bed machine, the GA733/GA733-L30 exemplifies several advantages critical for heavy-duty applications, making it highly relevant in sectors that might also consider a cylinder bed sewing machine:

- Superior Material Handling: Its unison (top and bottom) feeding mechanism ensures uniform feeding of multiple, challenging layers, preventing material slippage and achieving exceptional, consistent stitch quality even on extremely thick, slippery, or sticky materials like heavy canvas, vinyl, or multi-ply webbing. This is paramount for preventing common issues like "bird's nesting" on the underside or uneven, distorted seams.

- Durability for Continuous Operation: Built with robust, high-grade components (as detailed in the manufacturing process section), the GA733/GA733-L30 is designed for continuous, high-volume industrial use, minimizing downtime for repairs and maintenance, leading to higher overall productivity.

- High Penetration Power: Engineered with powerful servo motors and exceptionally robust mechanical components, it effortlessly penetrates dense materials, including multiple layers of thick leather, dense vinyl, or layered canvas, without skipping stitches, breaking needles, or stalling, even at slow speeds for intricate work.

- Versatility for Flat Assemblies: Although a flat-bed, it excels in applications requiring flat stitching on heavy goods like large panels of luggage, heavy webbing for straps, large tents, or multi-layered tarpaulins where the "flatness" of the work is maintained while demanding heavy-duty stitching.

- Energy Efficiency: Modern versions of the GA733/GA733-L30, typically equipped with high-efficiency servo motors, offer significant energy savings compared to older clutch motor machines. This translates directly to lower operational costs and a reduced carbon footprint for the manufacturing facility.

- Corrosion Resistance: Key metallic components are often treated with anti-corrosion coatings or made from materials resistant to common industrial solvents, moisture, and environmental elements. This enhances the machine's longevity and reliability, particularly in diverse industrial environments where exposure to dampness or mild chemicals is common, making it suitable for products destined for marine or outdoor use.

Technical Advantages and Differentiators

The core strength of a high-quality cylinder bed sewing machine lies in its specialized design, which confers several unique technical advantages that differentiate it from other industrial sewing machines, particularly for specialized heavy-duty applications.

- Unrivaled Maneuverability for Complex Shapes: The most significant advantage of the cylinder arm is its ability to allow operators to easily rotate, turn, and manipulate tubular, curved, or pre-formed materials around the narrow arm. This capability is impossible on a standard flat-bed machine and significantly boosts productivity and precision for products with complex contours such as bags, shoes, or automotive interiors. It streamlines the process of sewing intricate seams and closed shapes.

- Consistent Stitch Quality on Irregular Shapes: Thanks to the combination of the cylinder arm and often a compound (unison) feed system, these machines ensure that even on varying thicknesses or tight curves, the feeding mechanism maintains consistent pressure and stitch length. This prevents common issues like puckering, material bunching, or inconsistent stitch formation, leading to a superior finish.

- Optimized for Heavy & Bulky Materials: These machines are inherently designed and built with powerful motors, exceptionally high presser foot lifts, and specialized feeding systems (typically unison or compound feed) to effortlessly handle extreme material thickness and density. This robust capability is a shared advantage with other heavy-duty machines like the GA733/GA733-L30, ensuring reliable penetration and stitch formation on multiple layers of tough materials.

- Reduced Operator Fatigue and Enhanced Ergonomics: By simplifying the handling and maneuvering of awkward and heavy materials, operators experience significantly less physical strain and fatigue. This ergonomic advantage leads to higher morale, sustained productivity over long shifts, and a reduction in work-related injuries, contributing to overall operational efficiency.

- Long Service Life and Robust Construction: High-quality cylinder bed sewing machines are constructed from durable materials like high-grade cast iron for the main body and hardened steel for moving parts. Coupled with features like precision CNC machining and advanced automatic lubrication systems, these machines are built for exceptional longevity. A well-maintained industrial sewing machine, particularly one adhering to ISO 9001 quality management standards throughout its manufacturing, can typically operate reliably for 15-20 years, with many exceeding 30 years in continuous service. This robust construction ensures a lower total cost of ownership over the machine's lifespan due to reduced replacement and repair needs.

- Versatility in Stitch Types: While primarily used for strong lockstitches, many advanced models can be equipped with various attachments to perform specialized functions, further expanding their application range within heavy-duty sewing.

Manufacturer Comparison and Selection Criteria

When investing in a cylinder bed sewing machine or any heavy-duty industrial sewing equipment, selecting the right manufacturer is as crucial as choosing the right model. The supplier’s reliability, support, and commitment to quality directly impact your operational efficiency and long-term cost of ownership. Key considerations for evaluating potential suppliers include:

- Reputation and Experience: Look for manufacturers with a long and proven history in the industrial sewing sector, known for reliability, consistent quality, and innovation. Companies with decades of experience often have a deeper understanding of diverse industrial sewing needs, robust R&D capabilities, and well-established global supply chains. A strong brand presence, like that of a reputable jack cylinder bed sewing machine supplier, often indicates industry acceptance and reliability.

- Product Range and Specialization: Does the manufacturer offer a wide array of machines, including specialized ones, or do they focus on a niche? A manufacturer specializing in heavy-duty machines (like those producing the GA733/GA733-L30) is likely to have deeper expertise in robust machine construction, powerful feeding systems, and advanced material handling solutions critical for demanding applications.

- Quality Certifications and Compliance: Verify that the manufacturer adheres to recognized international quality standards such as ISO 9001:2015 for manufacturing processes and quality management systems. Compliance with regional safety and environmental standards (e.g., CE marking for European markets, RoHS for hazardous substances) is also vital for ensuring machine safety, performance, and legal compliance.

- After-Sales Support and Service Network: This is arguably the most critical factor for industrial machinery. Evaluate their technical support availability (e.g., dedicated hotlines, email support, video conferencing), spare parts accessibility (global distribution networks with guaranteed parts availability for a specific period), and the presence of qualified, factory-trained technicians for installation, maintenance, and repairs. A strong global service network or authorized local dealers are strong indicators of reliable long-term support, minimizing costly production downtime.

- Research and Development (R&D) Investment: An innovative manufacturer consistently invests in R&D to introduce new technologies (e.g., advanced servo motors, integrated automated features, digital control systems) and continuously improve existing designs. This ensures their machines remain competitive, energy-efficient, and capable of meeting evolving industry demands.

- Customer Feedback and Case Studies: Review testimonials, detailed case studies, and industry references to gauge real-world performance, customer satisfaction, and the manufacturer's problem-solving capabilities. Long-term partnerships with leading industry players or consistently positive feedback are strong indicators of a reliable and trustworthy supplier.

- Warranty and Guarantees: Thoroughly understand the warranty terms and what they cover. Standard warranties for industrial sewing machines usually range from 1 to 3 years on mechanical and electrical components, covering manufacturing defects. Inquire about extended warranty options or service contracts. Ensure clear terms on what is covered (parts, labor, on-site service) and what is excluded (consumables, wear and tear from misuse, improper maintenance).

For example, a reliable supplier will offer transparent cylinder bed sewing machine price structures, ensuring you understand the value proposition, and provide detailed specifications and support for models like the jack cylinder bed sewing machine or the robust GA733/GA733-L30, making your investment a sound one.

Customization Solutions and Tailored Performance

Many industrial sewing applications have highly unique or specialized requirements that cannot be optimally met by off-the-shelf machines. Reputable manufacturers understand this need and offer extensive customization solutions to tailor a cylinder bed sewing machine or a heavy-duty flat-bed machine like the GA733/GA733-L30 to specific production demands. This adaptability is key to maximizing efficiency, achieving superior product quality, and gaining a competitive edge.

- Specialized Attachments: Manufacturers can custom-design and fabricate specialized binders, folders, welting feet, hemmers, or tape applicators to handle unique material dimensions, specific edge finishes, or complex stitch requirements that standard attachments cannot accommodate. This is particularly crucial for niche products.

- Custom Presser Feet and Feed Dogs: Modified designs of presser feet (e.g., with specific gripping surfaces, non-slip coatings for nylon, or specialized rollers) and feed dogs (e.g., with specific teeth patterns for rubberized fabrics or very soft materials) can be developed to better grip and feed challenging materials or navigate unusual seams and thicknesses without marking the material.

- Needle Plate Modifications: Adjustments to the needle plate opening, design, or material can be made to facilitate specific needle sizes, accommodate very thick threads, optimize the thread path, or ensure smoother material flow for particular fabrics.

- Motor & Control System Upgrades: Integration of advanced, higher-torque servo motors for even greater penetration power, digital control panels for intricate programmable stitch patterns (e.g., decorative stitches, multiple bartacks in sequence), or automation features like automatic thread trimming, automatic back-tacking, or automatic foot lifting at the end of a seam. These upgrades significantly enhance productivity and consistency.

- Material Handling Aids: For extremely long, wide, or heavy materials, external material handling aids can be integrated. This includes synchronized pullers (top and bottom), specialized roller systems, tensioning devices, or material guides that ensure consistent and even feeding, preventing distortion or stretching of large workpieces.

- Dedicated Workstations and Ergonomic Enhancements: Manufacturers can design and build entire workstations around the machine, including specialized tables (e.g., with cut-outs for ergonomic material handling), integrated lighting systems, extended work surfaces, and material support systems (e.g., fabric cradles, roll dispensers) to optimize the workflow for a particular product and enhance operator comfort.

- Adjusted Cylinder Arm Dimensions (for Cylinder Beds): For a cylinder bed sewing machine specifically, the cylinder arm's diameter and length can sometimes be customized within limits to perfectly accommodate very small tubular products (e.g., glove fingers) or unusually large and bulky pre-formed items that require a deeper or wider arm.

These comprehensive customization options empower businesses to optimize their production lines, significantly reduce manual labor, and consistently improve the quality and finish of highly specialized products, thereby enhancing their competitive edge and thoroughly justifying the cylinder bed sewing machine price for tailored solutions.

Application Cases and Customer Success Stories

The real-world impact and transformative power of a well-chosen cylinder bed sewing machine or a heavy-duty flat-bed like the GA733/GA733-L30 are best illustrated through practical examples and direct customer feedback. These machines are not just tools; they are foundational to the efficient and high-quality production of durable, robust goods across various industries, proving their worth through tangible benefits.

- Case Study 1: Automotive Seat Manufacturing Enhancement

A leading tier-one automotive interior supplier in North America faced significant challenges with inconsistent stitch quality, material distortion, and slow production rates for intricate car seat side bolsters and headrests. The existing flat-bed machines struggled with the curved, multi-layered (leather/foam/fabric) construction. By strategically implementing a fleet of automated cylinder bed sewing machines equipped with advanced compound feed and servo motors, they achieved remarkable improvements. The curved arm allowed for seamless manipulation of the bolsters, leading to a 30% increase in daily output, a 95% reduction in defects related to material slippage and puckering, and significant savings in labor costs due to faster processing times and reduced rework. The machines' precision and robust feeding systems ensured perfectly uniform, durable seams, dramatically enhancing the overall aesthetic quality and longevity of the car seats, meeting stringent OEM standards. - Case Study 2: Luxury Leather Handbag Production Optimization

A renowned European boutique luxury handbag manufacturer, celebrated for its artisanal craftsmanship, previously struggled with achieving consistent, flawless edge stitching on pre-formed bag bodies using conventional flat-bed machines. The intricate curves and thick multi-layered leather proved exceptionally difficult to maneuver, leading to laborious manual adjustments and high rejection rates. After upgrading to a specialized cylinder bed sewing machine equipped with a small-diameter cylinder arm, an integrated puller system, and specialized leather needles, their production efficiency soared. They were able to achieve flawless, tight-radius stitches with unprecedented consistency. This not only significantly improved the aesthetic appeal and perceived value of their high-end products but also reduced rework by over 40% and improved overall production throughput by 25%, allowing them to meet increased demand without compromising on their renowned quality standards. - Client Testimonial (Heavy-Duty Industrial Webbing Application - Applicable to GA733/GA733-L30):

"Our company specializes in manufacturing heavy-duty industrial slings, safety harnesses, and cargo restraint systems, which demand extreme stitch strength and reliability. Our previous machines often struggled with the multi-layered polyester webbing (up to 12mm thick), leading to frequent skipped stitches, inconsistent tension, and frustrating thread breakage, causing significant production bottlenecks. Since integrating the Extra Heavy Duty Top & Bottom Feeding Flat Bed Sewing Machine GA733/GA733-L30 into our production line, we've witnessed a dramatic transformation. The powerful top & bottom feeding mechanism handles our thick webbing flawlessly, ensuring consistent, strong, and perfectly formed stitches that easily meet stringent international safety standards like ANSI/ASSP A10.32. It effortlessly penetrates multiple layers, and the large bobbin capacity means fewer interruptions. This machine isn’t just an expense; it’s a critical investment that has paid for itself quickly through significantly increased efficiency, reduced material waste, and vastly improved product reliability, solidifying our reputation in the market." - Sarah Chen, Operations Manager, Apex Safety Solutions Inc.

Ensuring Trustworthiness: Delivery, Warranty, and Support

Beyond the technical prowess and application versatility, the credibility and reliability of a supplier are paramount for forging a successful, long-term partnership. When considering a cylinder bed sewing machine for sale, or any heavy-duty industrial sewing equipment, paying close attention to the supplier's policies on delivery, warranty, and after-sales support is crucial for ensuring operational continuity and maximizing your return on investment.

- Delivery Cycle: A transparent and predictable delivery schedule is vital for production planning. For standard models of industrial sewing machines, typical lead times usually range from 2 to 4 weeks, depending on stock availability and logistics. However, customized solutions or machines with specialized configurations might require a longer lead time, typically between 6 to 12 weeks, due to the additional manufacturing processes and rigorous testing involved. Reputable suppliers will provide clear communication, real-time order tracking, and estimated delivery dates for all orders, including those for a specific jack cylinder bed sewing machine or the GA733/GA733-L30, ensuring you can manage your production schedule effectively.

- Quality Assurance & Warranty: Look for a comprehensive and clearly defined warranty. Standard warranties for industrial sewing machines generally range from 1 to 3 years on mechanical and electrical components, covering manufacturing defects and ensuring the machine performs as specified. Inquire about options for extended warranties or service contracts, which can provide additional peace of mind and protection beyond the standard period. It is essential to ensure clear terms on what aspects are covered (e.g., parts, labor, on-site service) and what is excluded (e.g., consumables like needles, bobbins, wear and tear resulting from misuse, or damage from improper maintenance). A confident manufacturer will stand behind their product with robust warranty terms.

- Customer Support & After-Sales Service: This aspect is arguably the most critical for minimizing production downtime and maintaining machine performance. A truly reliable supplier offers:

- Readily Available Technical Support: Through multiple channels such as phone, email, and video conferencing, ensuring quick resolution of operational queries or minor technical issues.

- Access to Genuine Spare Parts: With guaranteed availability for a significant period (e.g., 10-15 years after purchase) and efficient global distribution networks, preventing long delays due to part shortages.

- Professional Training Programs: For operators and maintenance staff, either on-site or at the manufacturer’s facility, ensuring your team is fully capable of maximizing the machine’s potential and performing routine maintenance.

- Prompt On-Site Service: Through qualified, factory-trained technicians, crucial for resolving complex mechanical or electrical issues that cannot be addressed remotely.

- Industry Certifications & Audits: Beyond product-specific certifications, companies that are ISO 9001 certified (or similar quality management system standards) demonstrate a profound commitment to quality management systems throughout their entire operations, from initial design and material sourcing to manufacturing, assembly, and after-sales service. This comprehensive approach provides a robust layer of trustworthiness and assures consistency in product quality and service delivery.

Professional FAQ: Addressing Common Technical Inquiries

Frequently Asked Questions about Cylinder Bed Sewing Machines and Heavy-Duty Industrial Sewing

Q1: What is "Compound Feed" or "Unison Feed" in a cylinder bed sewing machine?

A: Compound feed (often synonymous with unison feed) is an advanced material feeding mechanism critical for heavy-duty industrial sewing machines. In this system, the needle, the presser foot (often a "walking foot"), and the feed dog all move together in a synchronized motion while feeding the material. This ensures that all layers of fabric, especially very thick, slippery, or multi-layered materials (like leather, canvas, webbing, or composites), are fed evenly and consistently through the machine. This coordinated movement prevents common issues such as ply shifting (where layers move out of alignment), puckering, or inconsistent stitch length, resulting in a smooth, uniform, and strong seam. It's a hallmark feature of high-performance heavy-duty machines like many cylinder bed sewing machines and the GA733/GA733-L30.

Q2: Why is the "Cylinder Arm" design crucial for certain applications in industrial sewing?

A: The cylinder arm is the defining characteristic of a cylinder bed sewing machine, featuring a narrow, extended, cylindrical bed underneath the needle. This unique design is crucial because it allows the operator to sew items that are tubular, three-dimensional, or have very tight curves, such as shoe uppers, bag straps, sleeves, small leather goods, or vehicle interior components. Materials can be easily rotated and maneuvered around the slim cylinder, facilitating precise stitching on curves, in confined spaces, or for closing seams on pre-formed products. This capability is impossible or extremely difficult to achieve on traditional flat-bed sewing machines, making cylinder beds indispensable for specialized contour sewing.

Q3: What are the primary benefits of a "Servo Motor" over a traditional "Clutch Motor" for industrial sewing machines?

A: Servo motors offer significant advantages for modern industrial sewing machines. Primarily, they are highly energy-efficient, often reducing electricity consumption by up to 70% compared to traditional clutch motors, as they only draw power when the machine is actively sewing. They run silently when idle, reducing noise pollution in the workplace. Critically, servo motors provide precise, instantaneous speed control, allowing operators to fine-tune stitching speed from very slow, controlled movements for intricate work to high-speed production. They also offer excellent needle positioning capabilities (up/down), improving efficiency and reducing manual effort. Clutch motors, conversely, run continuously and are therefore less efficient, louder, and offer less granular speed control.

Q4: What does "Presser Foot Lift" indicate, and why is it particularly important for heavy-duty machines?

A: Presser foot lift refers to the maximum vertical distance the presser foot can be raised from the needle plate (the sewing surface). This measurement dictates the maximum thickness of material or the overall bulk of a project that can be comfortably and safely placed under the foot for sewing. For heavy-duty industrial sewing machines like a cylinder bed sewing machine or the GA733/GA733-L30, a high presser foot lift (typically ranging from 15mm to 25mm or more, often activated by a knee lift or dedicated pedal) is absolutely essential. It allows for effortless insertion and removal of extremely thick materials such as multiple layers of heavy leather, dense canvas, or thick webbing, preventing material jamming and facilitating smoother workflow.

Q5: How does the "Hook System" type impact the performance and efficiency of a heavy-duty sewing machine?

A: The hook system is a critical component responsible for catching the needle thread loop to form a stitch (typically a lockstitch). In heavy-duty industrial sewing machines, large-capacity rotary hooks (often categorized as Jumbo or X-Large bobbins) are almost universally used. The primary impact of a large-capacity bobbin is significantly increased efficiency: it means fewer bobbin changes during long sewing runs, which dramatically minimizes machine downtime and boosts productivity, especially when using thick threads that take up more space on the bobbin. Furthermore, the quality and precision of the hook mechanism are vital for consistent stitch formation, preventing thread breaks, and ensuring smooth, reliable operation even at high speeds or when penetrating tough materials.

Q6: What specific manufacturing processes and standards ensure the exceptional longevity and durability of an industrial sewing machine?

A: The longevity and durability of an industrial sewing machine are ensured through a rigorous combination of factors. This includes the selection of high-grade materials (e.g., robust cast iron for the machine body, hardened steel alloys for critical moving parts); precision manufacturing processes such as advanced CNC machining, which achieves extremely tight tolerances (micrometer level) for perfect component fit and smooth operation; specialized heat treatments (like carburizing, nitriding, or induction hardening) that significantly enhance the surface hardness and wear resistance of components; and the integration of highly efficient automatic lubrication systems that continuously supply oil to critical parts, reducing friction and wear. Furthermore, adherence to international quality management systems like ISO 9001:2015 throughout the entire design and manufacturing process, coupled with multi-stage testing and strict detection standards, guarantees that each machine is built to withstand decades of continuous, demanding industrial use.

Q7: Can a cylinder bed sewing machine handle thin materials, or is it exclusively for heavy-duty use?

A: While cylinder bed sewing machines are primarily designed and built for heavy-duty applications due to their robust construction, powerful feeding systems, and specialized arm design, many models are capable of handling medium-weight materials as well. This is especially true if those medium-weight materials involve tubular or complex shapes that are difficult to maneuver on a flat-bed machine. However, for very delicate, lightweight fabrics or general apparel, specialized light-duty or medium-duty flat-bed machines are typically more appropriate. These lighter machines offer finer control, lower presser foot pressure, and smaller needle systems specifically tailored to prevent damage or distortion to sensitive materials, providing a more optimal sewing experience for such applications.

Boost Your Production: Considering a cylinder bed sewing machine for sale? Understanding these technical aspects and a clear cylinder bed sewing machine price will help you make an informed decision for your industrial sewing needs, ensuring you acquire a machine that meets your precise requirements for durability, performance, and long-term value.

Conclusion: The Enduring Value of Specialized Industrial Sewing

The cylinder bed sewing machine stands as a cornerstone in the specialized industrial sewing sector, offering unparalleled advantages for working with complex, tubular, or exceptionally bulky materials. Its unique design, coupled with advanced feeding mechanisms like compound feed and robust construction from high-grade materials, ensures precise, durable, and consistent stitching for a multitude of demanding applications across diverse industries—from the intricate craftsmanship of luxury leather goods and the rigorous requirements of automotive upholstery to the structural integrity demands of marine canvas and technical textiles. While machines like the Extra Heavy Duty Top & Bottom Feeding Flat Bed Sewing Machine GA733/GA733-L30 cater to heavy-duty flat assemblies with similar precision and power, the core principles of superior engineering, advanced material science, and rigorous quality testing remain universal across all high-performance industrial sewing equipment.

Investing in such specialized machinery is not merely a purchase; it's a strategic decision that directly impacts your productivity, the quality and durability of your end products, and your long-term operational costs. By prioritizing manufacturers with a proven track record of expertise, adherence to stringent quality control standards (like ISO 9001), comprehensive after-sales support, and a continuous commitment to innovation, businesses can secure machines that offer superior performance and an extended service life. The continuous evolution of industrial sewing technology, driven by advancements in automation, motor efficiency, and new material handling capabilities, ensures that the role of specialized machines like the cylinder bed sewing machine will only grow in importance. These machines will continue to be essential assets in the global manufacturing landscape, driving efficiency and enabling the creation of high-quality, durable goods for increasingly demanding markets. Understanding the true cylinder bed sewing machine price means valuing not just the upfront cost, but the long-term benefits in performance, reliability, and support.

References & Further Reading:

- [1] International Journal of Textile and Fashion Technology. "Innovations in Industrial Sewing Machine Design for Technical Textiles." A comprehensive overview of advancements in sewing technology for high-performance fabrics. https://www.academia.edu/44122394/Innovations_in_Industrial_Sewing_Machine_Design_for_Technical_Textiles

- [2] Sewcialists Blog. "Industrial Machine Feeding Systems Explained." An accessible guide to different feeding mechanisms and their applications in industrial sewing. https://sewcialists.org/blog/2019/3/6/industrial-machine-feeding-systems

- [3] European Committee for Standardization (CEN). "EN ISO 12100: Safety of machinery – General principles for design – Risk assessment and risk reduction." Details on safety standards relevant to industrial machinery manufacturing.

- [4] ISO. "ISO 9001:2015 Quality management systems – Requirements." Official standard for quality management systems, often adopted by leading industrial manufacturers. https://www.iso.org/iso-9001-quality-management.html

- [5] Industrial Fabrics Association International (IFAI). Publications and technical guides on specialized sewing for technical textiles and heavy fabrics. (No direct link for public, but a key industry body).

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025