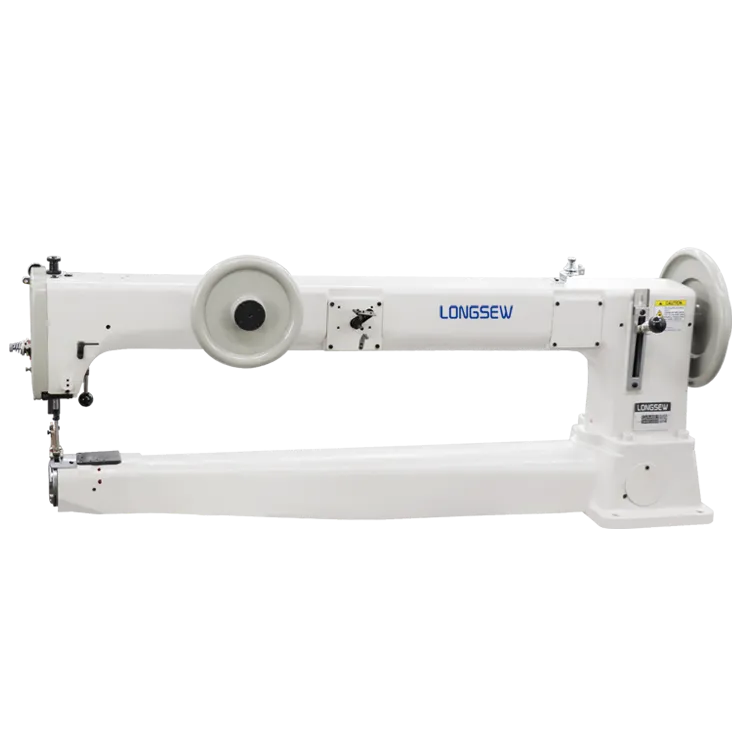

fibc sewing machine head

The Evolution and Importance of FIBC Sewing Machine Heads

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, have become the backbone of the logistics and industrial sectors, allowing for efficient transportation and storage of granular materials. The sewing machine head dedicated to manufacturing these bags plays a pivotal role in ensuring the durability and efficiency of the final product.

The Evolution and Importance of FIBC Sewing Machine Heads

Modern FIBC sewing machine heads are engineered for higher efficiency and adaptability. They come equipped with advanced features such as programmable stitching patterns, enhanced speed controls, and robust needle systems that can handle heavy-duty fabrics like woven polypropylene. This evolution has led to increased productivity, as manufacturers can now produce a higher volume of FIBCs within a shorter timeframe, thus meeting the rising demand in various sectors, including construction, agriculture, and chemicals.

fibc sewing machine head

Another crucial aspect of FIBC sewing machine heads is their ability to ensure quality control. Precision stitching is essential in bulk bag manufacturing to prevent any leakage or failure during transport and storage. Contemporary sewing machine heads are designed to execute consistent stitching under varying conditions, ensuring that each bag can withstand the rigors of handling and transportation. The durability of the sewing directly contributes to the bag's overall performance, making it essential to invest in high-quality sewing machine heads.

Moreover, the industry is witnessing a shift towards automation. Automated sewing machine heads increase production efficiency by minimizing human intervention and reducing the risk of error. This trend aligns with the increasing demand for sustainability and cost-effectiveness in manufacturing processes. Automated setups can operate continuously, requiring minimal downtime for maintenance, thus maximizing output and minimizing production costs.

In recent years, there has also been a growing emphasis on ergonomic designs in sewing machine heads. As operator safety and comfort become more crucial in modern manufacturing environments, manufacturers are developing machines that require less physical strain on workers. Features such as adjustable heights, user-friendly controls, and reduced noise levels are becoming standard, ensuring a better working environment for operators.

In conclusion, the evolution of FIBC sewing machine heads has revolutionized the production of bulk bags. By integrating technology and design improvements, manufacturers are not only enhancing productivity but also ensuring the quality and reliability of their products. As the demand for FIBCs continues to grow across various sectors, the importance of advanced sewing machine heads in maintaining competitive advantage cannot be overstated. This will likely drive further innovations, ensuring that the industry remains equipped to meet future challenges.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025