fibc loop sewing machine

FIBC Loop Sewing Machines Revolutionizing Bulk Packaging

In the world of packaging, especially for bulk materials, FIBC (Flexible Intermediate Bulk Container) bags have become a vital solution. These large, flexible bags are designed to hold everything from chemicals to agricultural products, and their effectiveness relies heavily on the quality of their seams. This is where FIBC loop sewing machines come into play, offering advanced technology for optimal manufacturing processes.

FIBC bags, often referred to as bulk bags or tote bags, are designed to carry significant weights, and their construction demands precision and strength. The bags typically consist of fabric made from woven polypropylene, which is incredibly durable yet lightweight. To ensure the contents are secure, the seams must withstand the stress of heavy loads. This requirement has led to the development of specialized sewing machines tailored to the unique needs of FIBC manufacturing.

FIBC Loop Sewing Machines Revolutionizing Bulk Packaging

One of the standout features of FIBC loop sewing machines is their ability to sew different types of loops. These loops are essential for the lifting and handling of the bags. FIBC bags typically feature four corner loops, allowing for easy loading and unloading with forklifts or other machinery. The sewing machines are capable of creating these loops with consistent strength and durability, ensuring that the bags can hold the required weight while minimizing the risk of failure.

fibc loop sewing machine

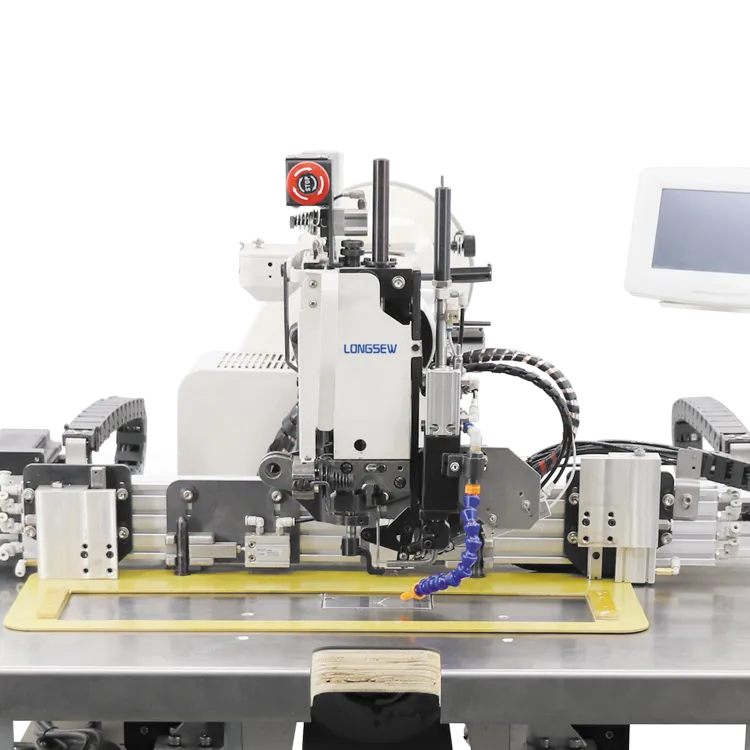

The automation of sewing machines has also transformed the FIBC manufacturing process. Modern FIBC loop sewing machines are equipped with computerized systems that enhance accuracy and consistency. These machines can be programmed to perform specific tasks, allowing for the rapid production of bags with identical specifications. This is particularly advantageous for companies aiming for large production runs, as it significantly reduces labor costs and time while improving quality control.

Environmental sustainability is becoming increasingly important in all fields, including packaging. Many manufacturers are now seeking eco-friendly materials and processes. FIBC loop sewing machines contribute to this movement by enabling the production of biodegradable or recyclable bulk bags, thereby reducing the environmental impact of packaging waste.

Furthermore, the versatility of FIBC loop sewing machines means they can be adapted for various applications. Whether for agriculture, food, construction, or chemical industries, these machines can be configured to meet diverse production needs. This flexibility allows manufacturers to cater to specific client requirements while maintaining high standards of quality.

In conclusion, FIBC loop sewing machines are integral to the production of high-quality bulk bags. Their specialized designs, automated features, and versatility make them indispensable in a rapidly evolving packaging landscape. As industries continue to prioritize efficiency and sustainability, the role of these machines in enhancing manufacturing processes will only grow, solidifying their importance in securing products and ensuring safe transportation. The future of bulk packaging looks robust, thanks to the remarkable technology behind FIBC loop sewing machines.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025