Exploring the Innovations and Benefits of Chain Stitching Machinery in Textile Industry

The Chain Stitching Machine An Essential Tool in Textile Manufacturing

In the realm of textile manufacturing, few machines have had as significant an impact as the chain stitching machine. This versatile equipment, known for its capacity to produce a secure and durable stitch, is a crucial asset in various sectors, including garment production, quilting, and upholstery. Its unique stitching mechanism and wide range of applications make it indispensable for professionals and hobbyists alike.

Understanding Chain Stitching

The chain stitch is a type of stitch that allows for flexibility and elasticity, making it ideal for fabrics that experience tension and movement. Unlike regular stitches, which rely on a single thread and needle, chain stitching uses a looped thread that creates a series of interconnected stitches. This design not only enhances the overall strength of the seam but also ensures that the stitching remains effective under stress. The result is a strong, resilient seam capable of withstanding the rigors of everyday use.

Versatility and Applications

One of the most appealing aspects of the chain stitching machine is its versatility. It is widely used in the production of various clothing items, including T-shirts, jeans, and sweatshirts. This machine is particularly favored in the construction of garments that require stretchy seams, as the chain stitch allows for ease of movement without compromising durability.

In addition to its use in garment manufacturing, chain stitching machines find applications in quilting and home décor projects. Quilters appreciate the efficiency and speed of these machines, which allows for the quick assembly of quilt layers and intricate designs. Upholsterers also utilize chain stitching for creating durable seams in furniture covers and cushions, ensuring that their products are both functional and aesthetically pleasing.

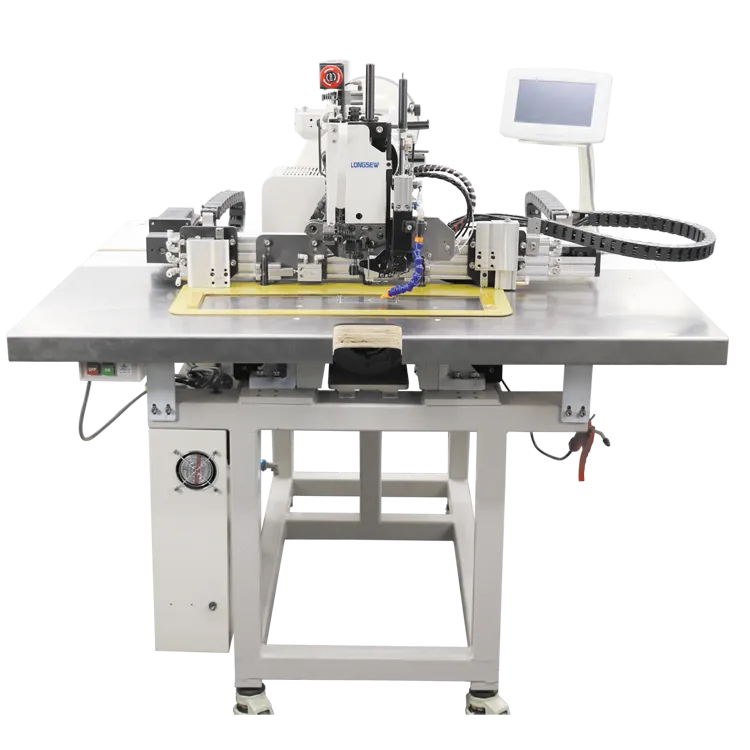

chainstitching machine

Technological Advancements

Over the years, chain stitching machines have evolved significantly, incorporating advanced technologies that enhance performance and ease of use. Modern machines often feature automatic thread tension adjustments, which help maintain consistent stitch quality regardless of fabric type. Additionally, computerized models offer programmable stitch patterns and speeds, allowing users to customize their projects with precision.

Safety features have also advanced, with many machines now equipped with automatic shut-off mechanisms and protective guards. These innovations not only promote safer working environments but also help reduce the risk of material waste and ensure product quality.

Maintenance and Care

To maximize the efficiency and longevity of a chain stitching machine, proper maintenance is essential. Regular cleaning to remove lint and debris, along with periodic oiling of moving parts, is crucial in preventing malfunctions and ensuring smooth operation. Additionally, users should periodically check the needle and thread tension to maintain consistent stitch quality.

Conclusion

The chain stitching machine has solidified its place as a cornerstone of the textile industry. Its ability to produce strong, flexible seams has made it a favorite among manufacturers and artisans alike. As technology continues to advance, the functionality and capabilities of these machines will only improve, providing users with enhanced productivity and creative opportunities. Whether in mass production or individual projects, the chain stitching machine is an essential tool that shapes and redefines the landscape of textile manufacturing. With its rich history and promising future, it will undoubtedly remain a fixture in workshops and factories for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025