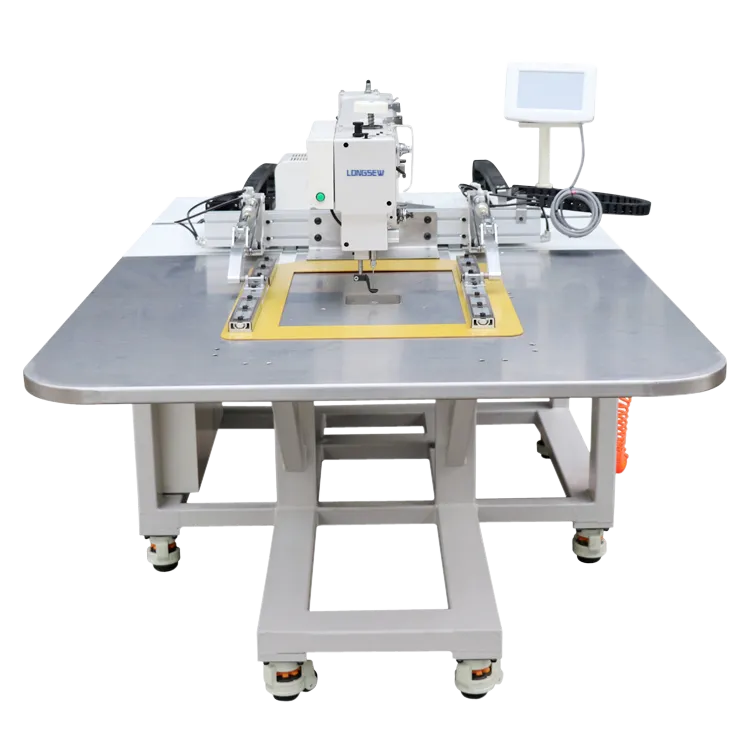

double stitch industrial sewing machine

The Double Stitch Industrial Sewing Machine A Key Player in Modern Manufacturing

In the realm of industrial manufacturing, the efficiency and precision of machinery are paramount. Among the various types of sewing machines that have emerged to meet the needs of the textile and garment industries, the double stitch industrial sewing machine has gained significant prominence. This machine not only streamlines the sewing process but also enhances product quality, making it an indispensable tool for manufacturers.

The double stitch industrial sewing machine is designed to create two parallel lines of stitching, which provides superior strength and durability compared to a single stitch. This feature is particularly advantageous for sewing fabrics that experience a high degree of stress, such as denim, upholstery, and heavy-duty materials. As a result, products sewn with double stitches are more resilient, which is crucial in industries that prioritize long-lasting goods, such as fashion and home textiles.

One of the standout benefits of using a double stitch machine is its efficiency. With the ability to sew multiple lines simultaneously, manufacturers can significantly reduce production time. This efficiency is not only beneficial for meeting tight deadlines but also plays a vital role in enhancing overall productivity. In a competitive market, being able to deliver high-quality products quickly can be a major differentiator for businesses.

double stitch industrial sewing machine

Moreover, the double stitch industrial sewing machine features advanced technology that allows for precise control over stitch length and tension. This adaptability ensures that manufacturers can achieve consistent results across different fabric types and thicknesses. Additionally, modern double stitch machines are often equipped with computerized controls and automation capabilities, further improving the speed and accuracy of the sewing process. With such technological advancements, the days of manual stitching errors and inconsistencies are becoming a thing of the past.

Maintenance is another important aspect of using industrial sewing machines. The double stitch machines are generally designed for heavy use, but like any machinery, they require regular upkeep to maintain optimal performance. Manufacturers typically invest in skilled technicians to perform routine maintenance checks, ensuring that the machines run smoothly and efficiently. This proactive approach helps prolong the lifespan of the equipment and minimizes unexpected downtime during production.

In conclusion, the double stitch industrial sewing machine is a crucial asset in contemporary manufacturing. By offering enhanced durability, improved efficiency, and precise control, it meets the evolving demands of the textile and garment industries. As manufacturers strive to balance quality with speed, the double stitch machine stands out as a reliable solution that not only meets production needs but also upholds the standards of craftsmanship. As technology continues to advance, we can expect the capabilities of these machines to expand further, solidifying their role in shaping the future of industrial sewing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025