ফেব্রু. . 11, 2025 19:16

Back to list

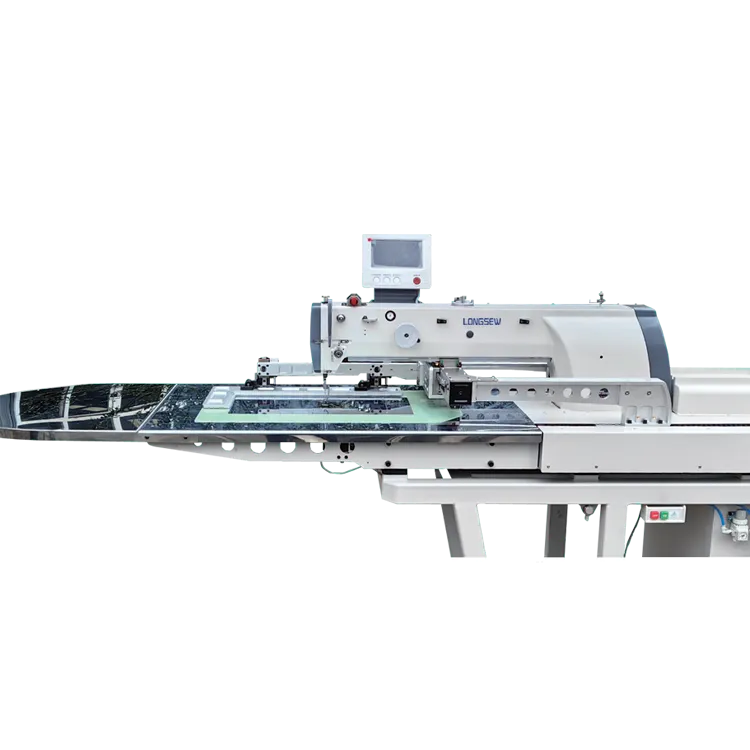

cylinder leather sewing machine

Cylinder leather sewing machines have increasingly become a staple in the textile and leather industries due to their versatile application and robust build. Professionals seeking precision and quality in leather stitching often turn to these machines. Below, we delve into a comprehensive analysis of the advantages, functionality, and application suitable for diverse leather crafting needs.

Selecting the right cylinder leather sewing machine requires consideration of several factors, including the type of leatherwork, frequency of use, and desired production outcomes. Choosing a machine that accommodates a variety of stitches, from decorative to functional, can significantly impact the versatility and breadth of projects one can undertake. Investing in a high-quality cylinder leather sewing machine also involves understanding the maintenance requirements to ensure longevity and consistent performance. Regular cleaning, timely oiling of parts, and routine checking of needle and thread compatibility are essential practices for keeping the machine in peak condition. These maintenance tasks not only increase the machine's lifespan but also enhance its stitching precision and efficiency. Cylinder leather sewing machines are renowned for their exceptional durability and ability to empower creators with the tools needed to express innovation through leather. As leather crafting continues to evolve, these machines continue to play an integral role, serving as reliable partners for artisans who seek to produce high-quality and aesthetically pleasing products. When considering the purchase of a cylinder leather sewing machine, one must evaluate the brand's reputation for reliability, customer support, and parts availability. Reliable brands offer extensive warranties, which reflect their confidence in their products, thus adding an extra layer of trustworthiness. Knowing that ongoing technical support and replacement parts are accessible ensures minimal disruptions during production and maximizes workflow efficiency. In conclusion, cylinder leather sewing machines are indispensable tools for any serious leather artisan. Their design facilitates detailed and robust stitching, enabling creators to construct superior leather products. By comprehending the mechanics, selecting appropriately, and maintaining these machines diligently, artisans can ensure sustained excellence in their craft, build a reputable brand, and deliver prized products that resonate with quality and authenticity.

Selecting the right cylinder leather sewing machine requires consideration of several factors, including the type of leatherwork, frequency of use, and desired production outcomes. Choosing a machine that accommodates a variety of stitches, from decorative to functional, can significantly impact the versatility and breadth of projects one can undertake. Investing in a high-quality cylinder leather sewing machine also involves understanding the maintenance requirements to ensure longevity and consistent performance. Regular cleaning, timely oiling of parts, and routine checking of needle and thread compatibility are essential practices for keeping the machine in peak condition. These maintenance tasks not only increase the machine's lifespan but also enhance its stitching precision and efficiency. Cylinder leather sewing machines are renowned for their exceptional durability and ability to empower creators with the tools needed to express innovation through leather. As leather crafting continues to evolve, these machines continue to play an integral role, serving as reliable partners for artisans who seek to produce high-quality and aesthetically pleasing products. When considering the purchase of a cylinder leather sewing machine, one must evaluate the brand's reputation for reliability, customer support, and parts availability. Reliable brands offer extensive warranties, which reflect their confidence in their products, thus adding an extra layer of trustworthiness. Knowing that ongoing technical support and replacement parts are accessible ensures minimal disruptions during production and maximizes workflow efficiency. In conclusion, cylinder leather sewing machines are indispensable tools for any serious leather artisan. Their design facilitates detailed and robust stitching, enabling creators to construct superior leather products. By comprehending the mechanics, selecting appropriately, and maintaining these machines diligently, artisans can ensure sustained excellence in their craft, build a reputable brand, and deliver prized products that resonate with quality and authenticity.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025