Optimizing Bag Closure Techniques for Enhanced Packaging Efficiency and Security

The Bag Closing System An Essential Component in Packaging

In today's fast-paced world, the efficiency of packaging processes plays a pivotal role in manufacturing and distribution across various industries. One critical aspect of this process is the bag closing system, a technology that ensures products are securely packaged, safe from environmental factors, and ready for transport. This article explores the significance of bag closing systems, their types, functionalities, and the innovations driving their development.

Understanding Bag Closing Systems

A bag closing system is a mechanism or machine designed to seal bags after they have been filled with products. These bags can contain anything from grains and powders to medical supplies and consumer goods. The primary purpose of these systems is to protect the contents from contamination, spillage, and deterioration, while also providing a tamper-proof seal that assures the integrity of the product to consumers.

Types of Bag Closing Systems

There are several types of bag closing systems available, each tailored for specific applications and materials

1. Heat Sealers These machines use heat to bond thermoplastic materials at the top of the bag, creating a strong seal. They are ideal for plastic bags and are commonly used in food packaging. The ability to adjust temperature settings ensures that the seal is both efficient and effective.

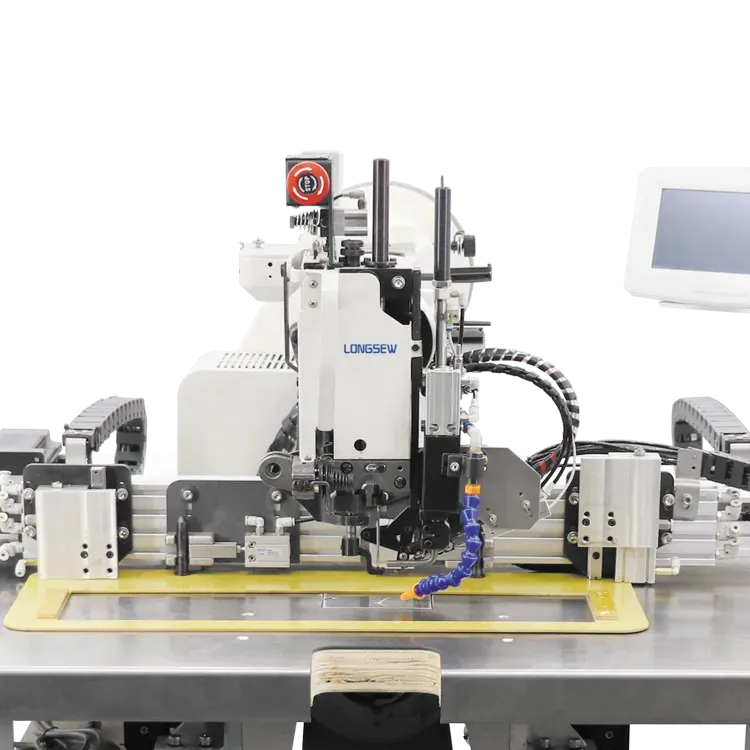

2. Sewing Machines Some industries prefer to use sewing machines that stitch the bags closed. This method is particularly effective for heavier materials, such as burlap or cloth bags. The stitched closure offers a robust and durable seal, making it ideal for agricultural or bulk food products.

3. Adhesives Adhesive sealing involves applying a special glue that adheres the bag's opening together. This method is versatile and popular in cases where other sealing techniques may not be feasible or cost-effective.

4. Compression Sealing This process involves placing the bag in a chamber where pressure is applied to the opening, allowing for a secure closure without heat or stitching. It is increasingly used in vacuum packaging systems to extend shelf life.

bag closing system

5. Twist Ties and Clips For lower-volume applications or retail packaging, twist ties or clips are often used to secure the bag opening. While less secure than other methods, they provide an economical and user-friendly option.

The Importance of Efficiency and Reliability

The success of manufacturing and distribution heavily depends on the efficiency and reliability of bag closing systems. A slow or malfunctioning closing system can lead to bottlenecks in production lines, resulting in increased labor costs and delayed shipments. Therefore, investing in high-quality bag closing systems can enhance overall operational efficiency, resulting in faster turnaround times and improved customer satisfaction.

Moreover, reliability is crucial in ensuring that products reach consumers in perfect condition. Any breach in packaging can lead to contamination or damage, which not only results in financial losses but can also harm a company's reputation. Thus, selecting an appropriate bag closing system tailored to the specific product and packaging environment is essential.

Innovations in Bag Closing Technology

As industries evolve, so too do bag closing systems. Advancements in technology are paving the way for smarter, more efficient packaging solutions. For instance, automated bag closing systems can integrate with filling machines to streamline the entire packaging process. These systems can offer features such as adjustable sealing settings, real-time monitoring, and data collection to optimize performance.

Additionally, environmentally friendly sealing options are gaining popularity as companies strive to reduce their carbon footprint. Innovations such as biodegradable adhesives and recyclable materials are being explored to make packaging more sustainable without compromising on durability or protection.

Conclusion

The bag closing system is a crucial element in the packaging process that ensures product integrity, safety, and efficiency. With various methods to choose from and continuous innovations driving improvements, businesses can tailor their packaging solutions to meet specific needs. Investing in reliable and advanced bag closing technology not only enhances operational productivity but also safeguards brand reputation through the secure delivery of high-quality products. As markets evolve and consumer expectations rise, the importance of efficient bag closing systems will only continue to grow.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025