bag closing system

Understanding the Bag Closing System A Key to Efficiency in Packaging

In a world that relies heavily on efficient packaging solutions, the bag closing system has emerged as a crucial element in the production line of various industries. This system, designed to securely seal bags, is vital for maintaining product integrity, ensuring freshness, and reducing waste. Here, we explore the significance and operation of bag closing systems, highlighting their advantages and the technology driving them.

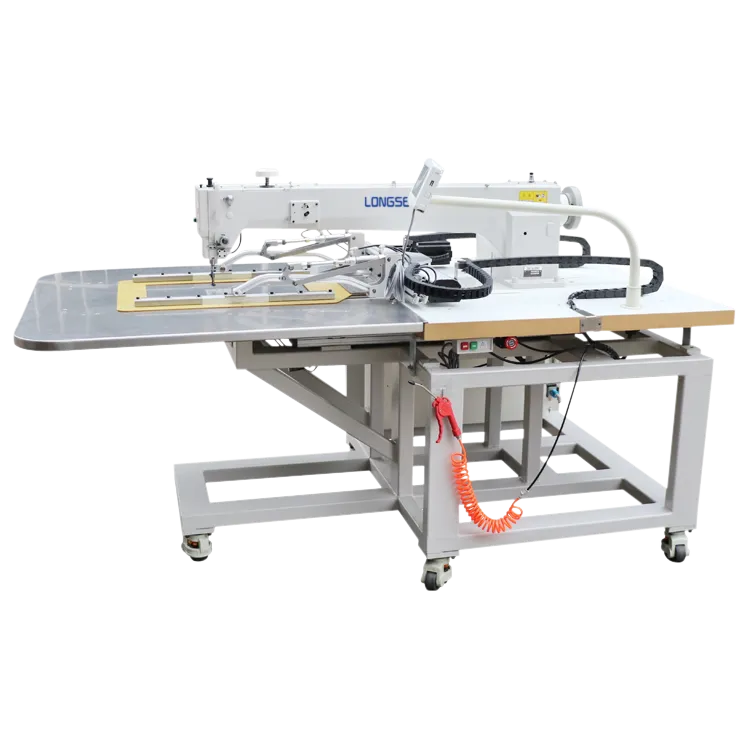

At its core, a bag closing system involves sealing the open ends of bags containing various products, such as food items, agricultural produce, chemicals, or pharmaceuticals. The method of closure can vary, ranging from heat sealing and stitching to adhesive applications. Each method offers distinct benefits tailored to specific types of products and storage requirements.

Heat sealing is one of the most prevalent methods used in bag closing systems. By applying heat to the edges of plastic bags, the system creates a strong bond that ensures airtight containment. This is particularly beneficial for perishable goods, as it prevents spoilage and extends shelf life. In contrast, stitching is often used for bags made of fabric or paper. Industrial sewing machines equipped with specialized thread can firmly secure the bags, making this technique suitable for heavy-duty applications.

bag closing system

The efficiency of a bag closing system is further enhanced by automation. Modern systems often incorporate advanced technology such as sensors, automatic bag feeding, and integrated quality control mechanisms. These innovations allow for high-speed operations, reducing the need for manual intervention and minimizing human error. As a result, manufacturers can achieve higher throughput, ultimately leading to reduced operational costs and increased productivity.

Moreover, employing an automated bag closing system can significantly improve workplace safety. By minimizing physical handling of products, the risk of accidents and injuries can be decreased. Additionally, by ensuring bags are sealed correctly, companies can avoid costly product recalls due to contamination or mislabeling, safeguarding their reputation and bottom line.

Sustainability is another important consideration in the contemporary packaging landscape. With growing awareness regarding environmental impact, many bag closing systems utilize eco-friendly materials and energy-efficient technologies. This shift not only meets regulatory standards but also resonates with environmentally conscious consumers.

In conclusion, the bag closing system is a fundamental component of the packaging industry that directly impacts product quality, operational efficiency, and sustainability. As technology continues to evolve, we can expect further advancements that enhance these systems, driving greater innovation in how we package and protect products across diverse sectors. Investing in a reliable bag closing system is thus not just a matter of compliance; it is a strategic choice that can lead to significant gains in efficiency and market competitiveness.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025