Innovative Sewing Technology for Effortless Dressmaking and Custom Tailoring Solutions

The Evolution of Automatic Dress Stitching Machines

In the ever-evolving world of fashion and garment manufacturing, the emergence of automatic dress stitching machines has revolutionized the way clothing is produced. These sophisticated machines have not only increased efficiency and productivity but have also enhanced the quality of the finished products, making them indispensable in modern garment factories.

Automatic dress stitching machines are designed to perform a wide variety of stitching operations with minimal human intervention. Equipped with advanced technology, these machines can execute complex stitching patterns, perform multiple sewing techniques, and even adapt to different fabric types. This versatility is a significant advantage over manual stitching, where the skill level of the operator can greatly affect the quality and speed of production.

One of the most significant benefits of automatic dress stitching machines is their ability to drastically reduce production time. Traditional sewing methods often require several skilled laborers to complete a single garment, leading to increased labor costs and longer lead times. In contrast, automatic machines can stitch an entire dress in a matter of minutes, allowing manufacturers to meet the high demand for fast fashion without compromising quality. This efficiency not only improves profit margins but also enables retailers to respond swiftly to changing fashion trends.

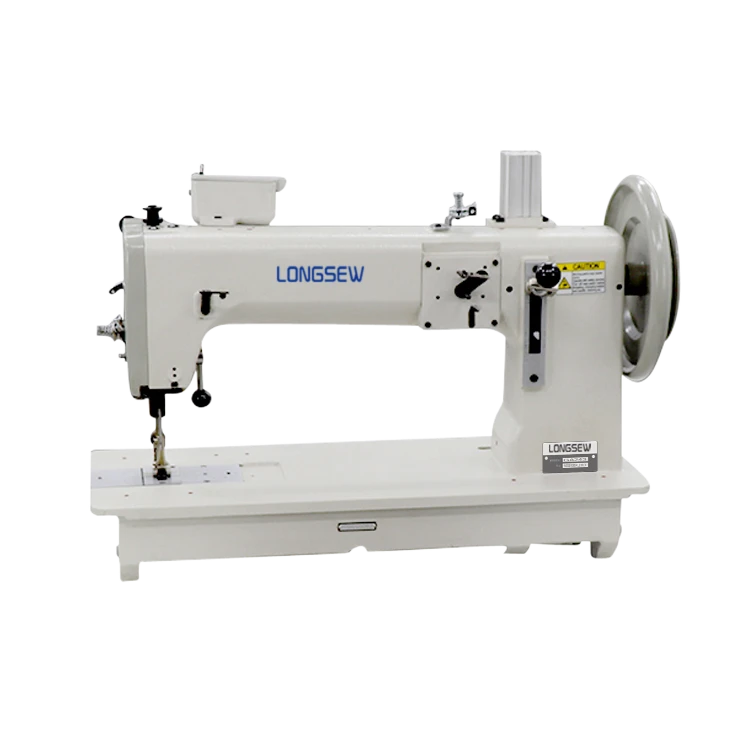

automatic dress stitching machine

Moreover, the precision offered by automatic machines is unparalleled. They are programmed to ensure that each stitch is uniform and accurate, resulting in a polished finish that manual sewing often struggles to achieve. This consistency is crucial in the fashion industry, where the smallest details can significantly influence a garment's overall appeal. Furthermore, the integration of computer-aided design (CAD) technology allows designers to create intricate patterns and styles that can be consistently replicated by the machine, ensuring that the designer's vision is accurately executed on a large scale.

As sustainability becomes an increasingly pressing issue in the fashion industry, automatic dress stitching machines also offer potential eco-friendly benefits. By streamlining production processes and reducing fabric waste, these machines contribute to more sustainable manufacturing practices. Automation can optimize fabric usage, minimizing leftovers and reducing the environmental impact associated with textile waste. Furthermore, faster production times mean that manufacturers can react quickly to market demands, potentially curbing overproduction and the associated waste that comes with unsold inventory.

However, the rise of automatic dress stitching machines also raises questions about the future of the workforce in the garment industry. As these machines become more prevalent, there is concern over job displacement for skilled seamstresses and tailors. While it is true that some lower-skilled positions may be replaced, it is also essential to recognize that the demand for high-level technical skills in operating and maintaining these machines will increase. Workers will need to adapt to this new landscape by acquiring training in advanced sewing techniques, machine operation, and troubleshooting, ensuring that they remain relevant in a technology-driven industry.

In conclusion, automatic dress stitching machines represent a significant advancement in garment manufacturing. Their efficiency, precision, and potential for sustainability are transforming the fashion industry, enabling manufacturers to produce high-quality garments at an unprecedented pace. While challenges remain regarding workforce adaptation, the overall impact of these machines is paving the way for a more innovative and responsive fashion industry, setting the stage for the future of apparel production. As technology continues to advance, the journey of automatic dress stitching machines will undoubtedly reshape how we conceive clothing, pushing the boundaries of creativity and efficiency in fashion.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025